Rice collecting and impurity removing machine

A technology for removing impurities and machines, applied in the fields of motor vehicles, chemical instruments and methods, solid separation, etc., can solve the problems of low work efficiency, large workload, inability to adjust the speed of rice impurity removal, etc., to improve work efficiency and reduce work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

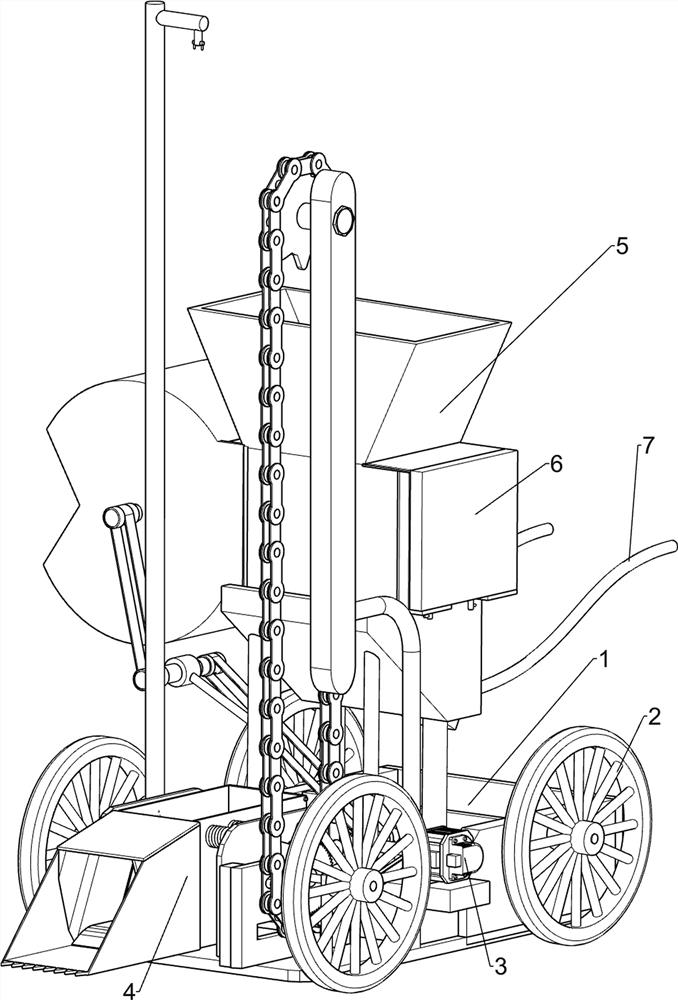

[0060] A machine for collecting and removing impurities from rice, such as figure 1 As shown, it includes a support plate 1, a wheel 2, a motor 3, a loading and rotating mechanism 4, a collecting and removing impurity mechanism 5 and a handle 7, and the left and right sides of the support plate 1 are connected with the wheels 2 in a forward and backward symmetrical rotation type. A motor 3 is installed in the middle of the support plate 1. A loading and rotating mechanism 4 is provided on the top front side of the support plate 1. The loading and rotating mechanism 4 is connected to the output shaft of the motor 3. A collection and removal mechanism 5 is provided in the middle of the top of the support plate 1 to collect and remove impurities. The left and right sides of the lower rear part of the mechanism 5 are provided with handles 7 .

[0061]When people need to remove impurities from rice, people first place the rice collection frame under the parts of the collecting and ...

Embodiment 2

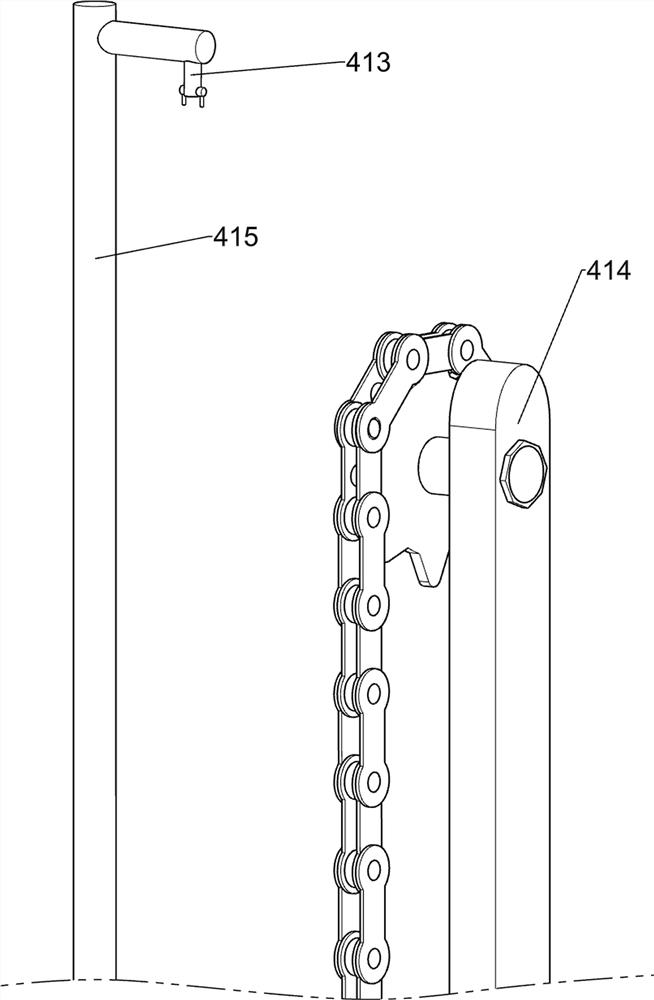

[0063] On the basis of Example 1, such as Figure 2-5 As shown, the loading and rotating mechanism 4 includes a dustpan 41, a first connecting plate 42, a sliding sleeve 43, a torsion spring 44, a rotating baffle plate 45, a second connecting plate 46, a chain 47, a pulley combination 48, and a first fixed rod 49 , reduction gear 410, linkage gear 411, slider 412, auxiliary offset rod 413, second fixed rod 414, slide rod 415, sprocket wheel 416 and first rotating rod 417, the right front side of the top of the support plate 1 is provided with a first Fixed rod 49, the top of the first fixed rod 49 is rotatably connected with linkage gear 411, the right side of the transmission shaft of linkage gear 411 and the output shaft of motor 3 are connected with pulley assembly 48, the left front side of support plate 1 is provided with slide bar 415, The top of the slide bar 415 is provided with an auxiliary offset bar 413, the slide bar 415 is slidably connected with a sliding sleeve ...

Embodiment 3

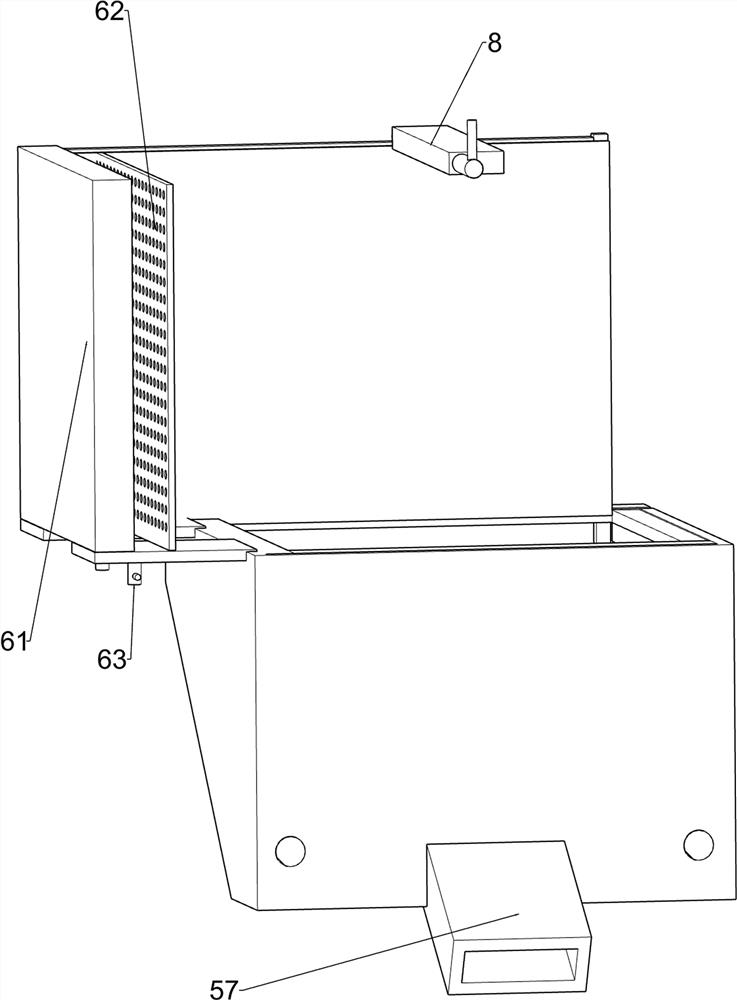

[0068] On the basis of Example 2, such as Image 6 Shown, also include to collect residue mechanism 6, collect residue mechanism 6 and include baffle plate 61, mesh screen 62 and hook 63, the right part of miscellaneous box 59 is provided with baffle plate 61, and the bottom of baffle plate 61 is provided with Square groove, both sides front and back of object baffle 61 bottoms are all provided with hook 63, are connected with screen 62 between the bottom right side of object baffle 61 inwall bottoms and the top right side of 59 inwalls of removal box, on mesh sieve 62 evenly be provided with hole.

[0069] When people need to collect the impurities in the rice, people can hang the impurity collection bags on the hooks 63 on the front and rear sides. When the fan blades 55 rotate, the air flow driven by the fan blades 55 drives the impurities to move to the right. Under the cooperation of the sieve 62, the impurities fall into the impurity collection bag from the square hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com