Preparation method of aluminum alloy complex component product with bidirectional curvature

An aluminum alloy and curvature technology, which is applied in the field of aerospace propellant storage tanks, can solve the problems of insufficient success rate and long heat preservation time of formed aluminum alloy components, and achieve the goals of improving mechanical properties, reducing heat preservation time, and improving forming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

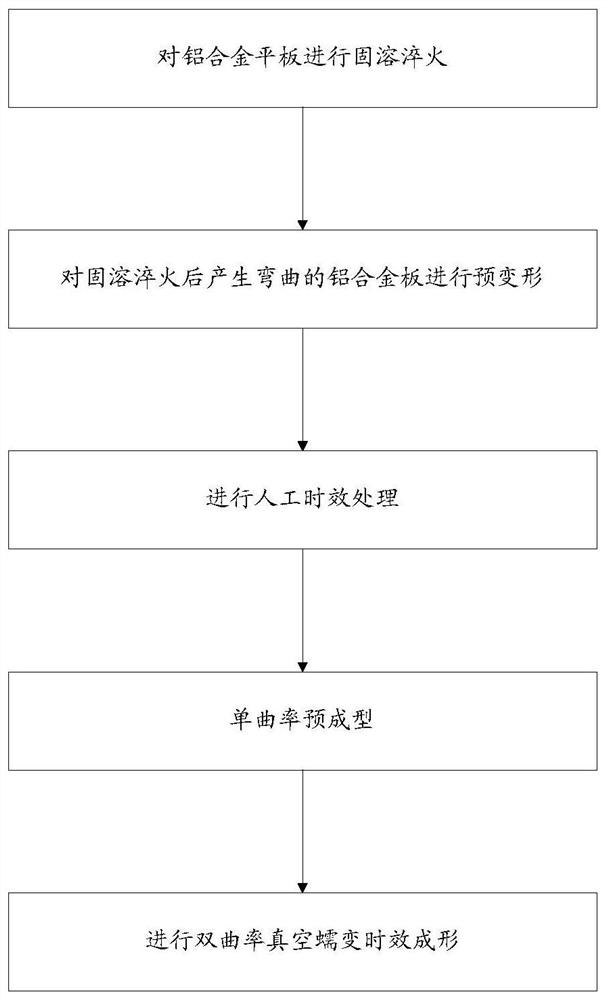

[0033] Such as figure 1 Shown, the preparation method of the aluminum alloy component product of a kind of bidirectional curvature of the present invention, comprises the following steps:

[0034] Step A: Perform solution treatment on the aluminum alloy plate in an electric furnace, the temperature of the solution treatment is 480-560°C, the time of the solution treatment is 20-80 minutes, and then spray and quench with water; the aluminum alloy plate is 2219 aluminum alloy plate;

[0035] Step B, using a cold forming step combining drawing and rolling to pre-deform the bent aluminum alloy plate after solution quenching with a deformation amount of 8-10%;

[0036] Step B makes the aluminum alloy plate that has become somewhat curved after solution quenching return to flatness. The purpose of pre-deformation of the aluminum alloy sheet in this step is to smooth the deformed aluminum alloy sheet after solution quenching and reduce residual stress, and the other is to facilitat...

Embodiment 1

[0051] The method of the invention is used to prepare aluminum alloy component products with two-way curvature.

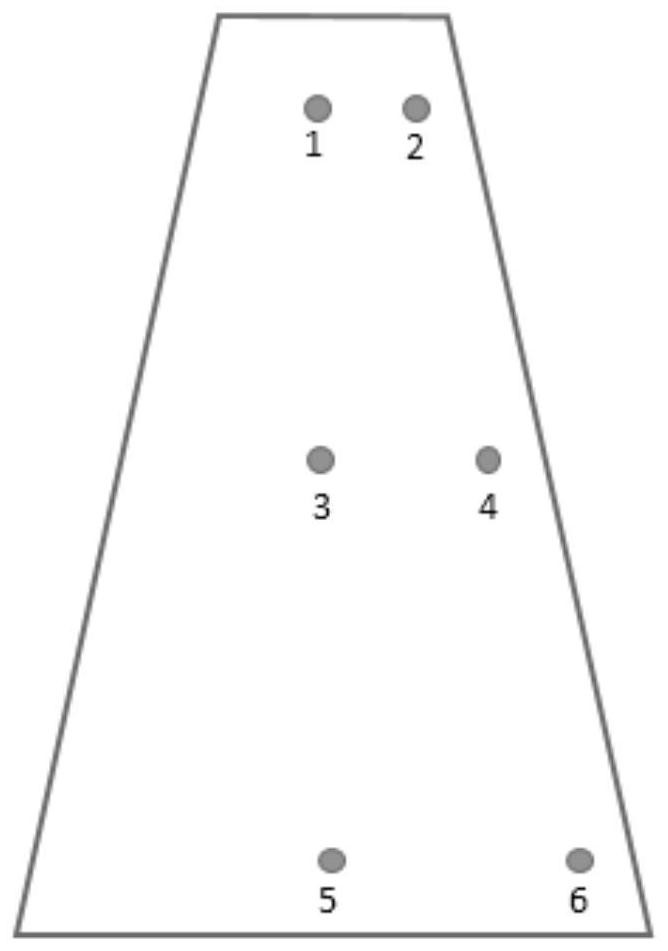

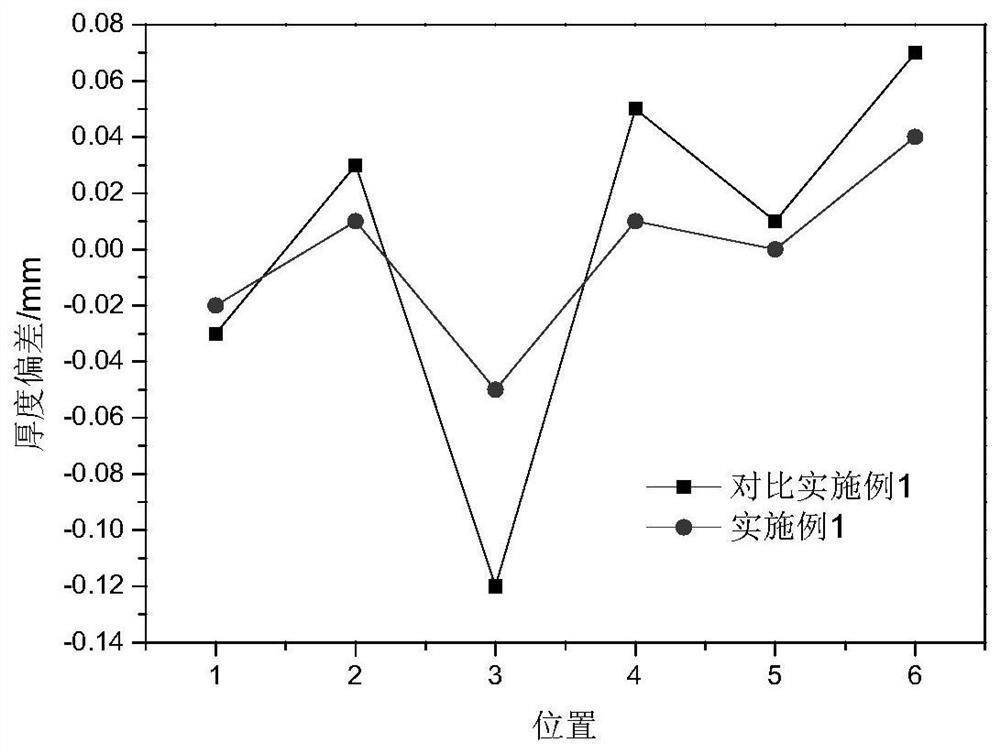

[0052] The 2219 aluminum alloy plate is subjected to solution treatment in an electric heating furnace. The temperature of the solution treatment is 535 ° C, the solution is 45 minutes, and then water is sprayed and quenched; the deformation of the aluminum alloy plate after solution quenching is 8% Deformation; place the aluminum alloy plate in an aging furnace for artificial aging, and treat it at 175°C for 8 hours; perform single-curvature preforming on the aluminum alloy plate, and the time for single-curvature preforming is about 20 minutes; The final aluminum alloy curved plate is subjected to double-curvature vacuum creep aging forming. The temperature in the autoclave is raised to 180°C and the pressure is increased to 0.6MPa, and the heat preservation and pressure are kept for about 3 hours. After cooling down, the formed aluminum alloy is obtained. alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com