Casting method of stainless steel water cooling pipe pre-embedded mold

A water-cooled tube and stainless steel technology, which is applied in casting molding equipment, molds, mold components, etc., can solve the problems of poor effect and high cost, and achieve the effect of good effect, low cost and free design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

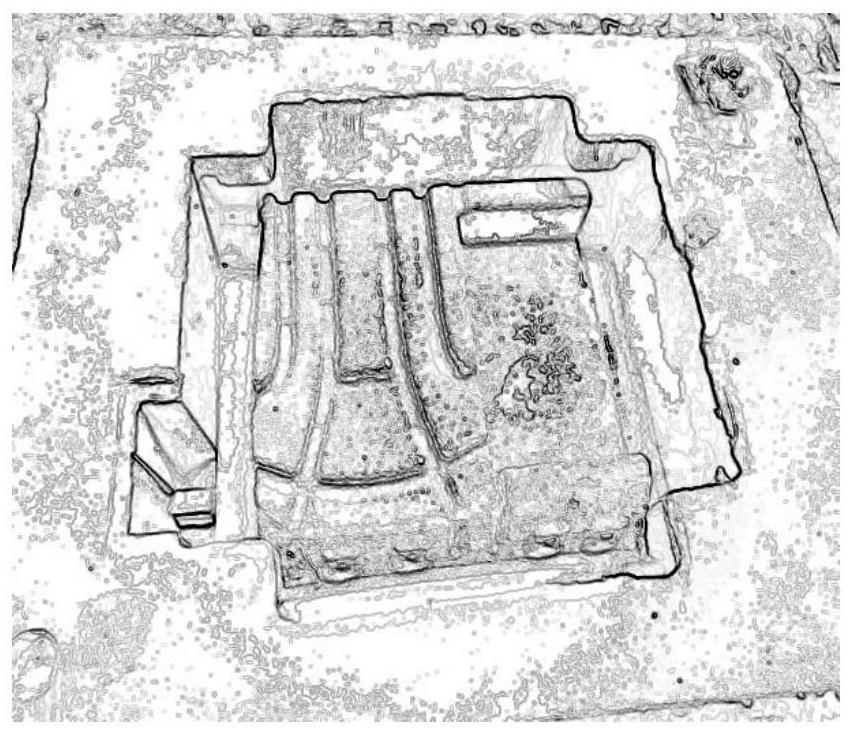

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

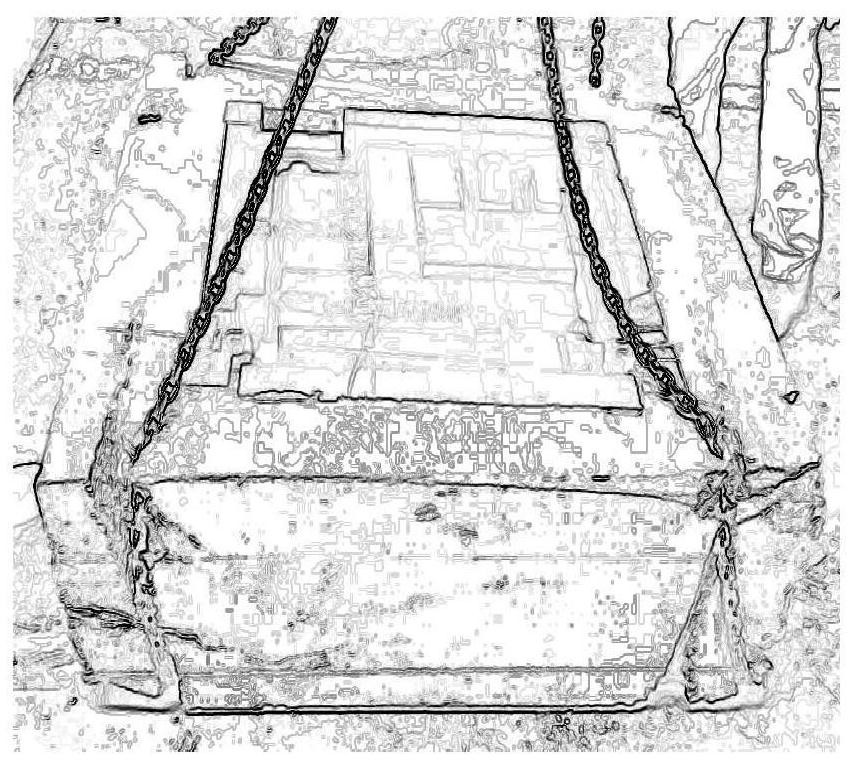

[0036] For mold water cooling purposes, refer to Figure 8 , the water-cooled pipe pre-embedded casting technical scheme of the present invention is as follows:

[0037] The first step is to use the CNC machining center to process a set of polystyrene foam molds and bend the stainless steel tubes into water-cooled tubes according to the required water-cooling path.

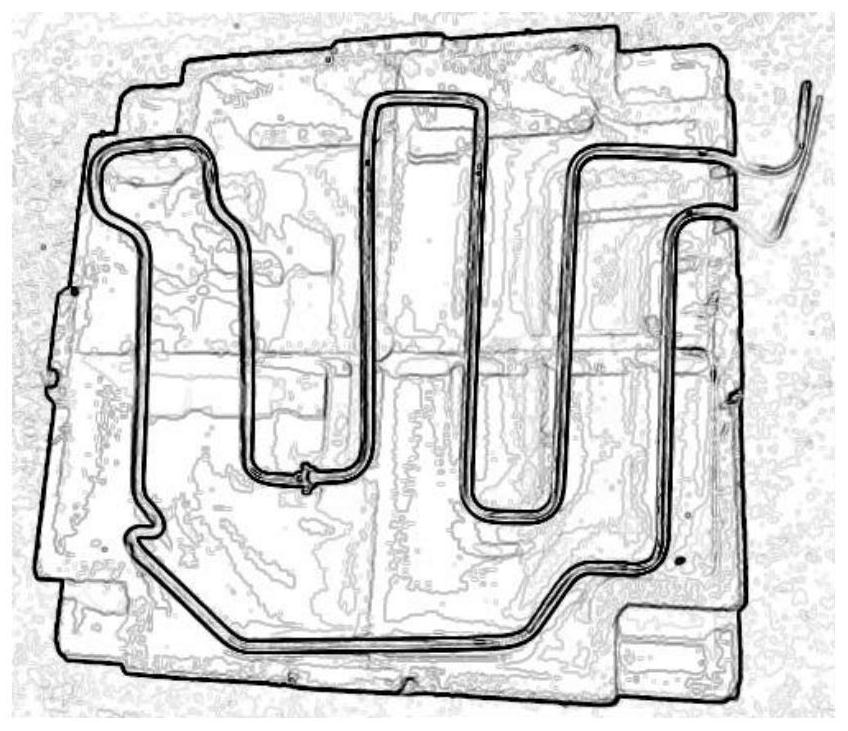

[0038] refer to figure 1 , figure 1 A schematic diagram of the pre-assembly of the water cooling tube and the white mold;

[0039] The white mold refers to the polystyrene foam mold;

[0040] "White mold" is processed by CNC machining center according to the needs of polystyrene sheet.

[0041] The water-cooled pipe is based on the cooling water cooling path given in the design, using a pipe bender or pipe bending fixture to bend the stainless steel pipe into a pipe of the shape required by the design.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com