Method for preparing rollable nano-paper-based flexible solar cells by 3D airgel jet printing

A technology of solar cells and jet printing, applied in nanotechnology, nano optics, nanotechnology, etc., can solve the problems of different dispersion and preparation conditions, no high haze, material waste efficiency, etc., and achieve the free design of hierarchical structure , reduce battery structure damage, and achieve the effect of one-time molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

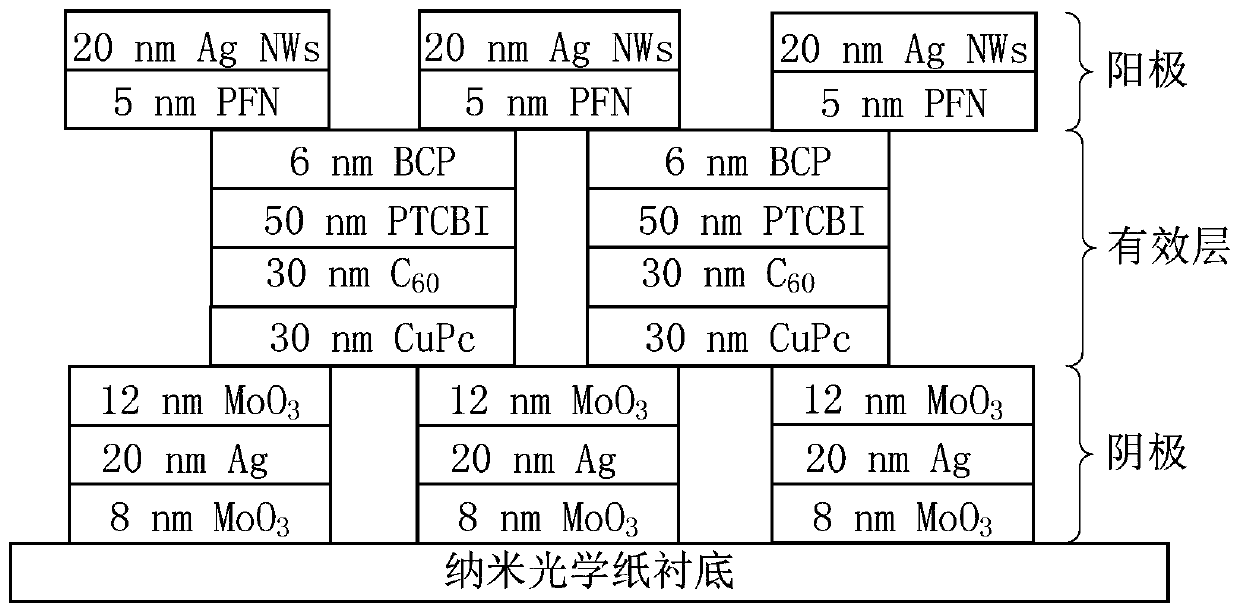

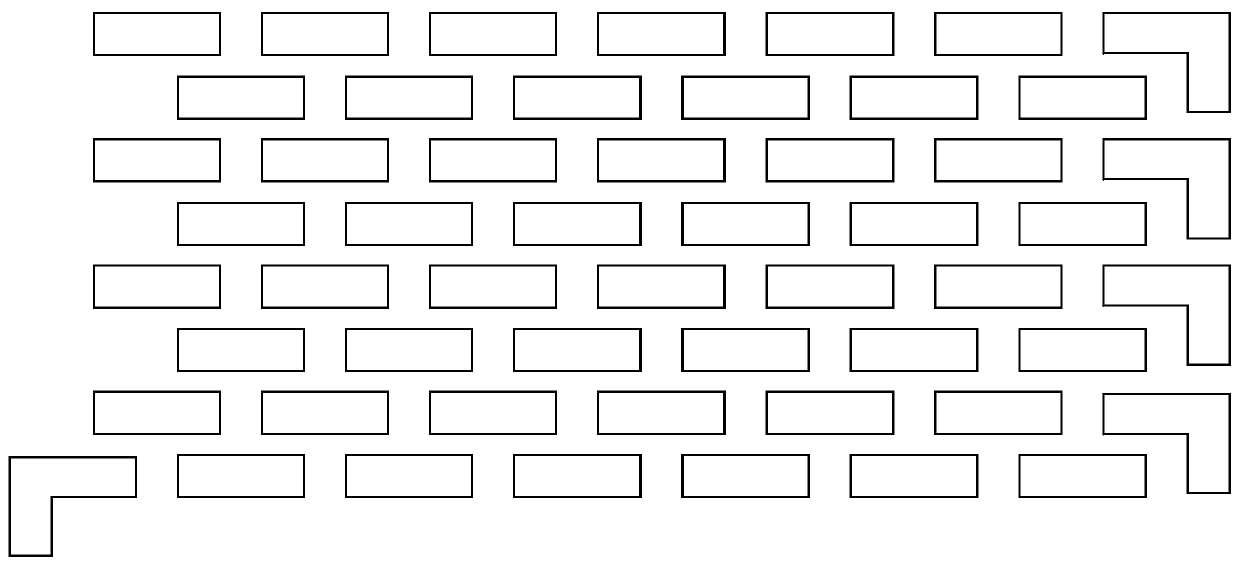

[0044] A method for preparing rollable nano paper-based flexible solar cells by 3D airgel jet printing, comprising the following steps and process conditions:

[0045] A) Preparation of flexible paper-based nano-optical paper: using ionic liquid to directly soak the whole cellulose base paper, and then heat-rolled to regenerate and prepare the nano-optical paper substrate, including the following steps:

[0046] 1) Use ionic liquid (N-ethylimidazolium hydrogen phosphite) to soak the whole cellulose paper (double-circle medium-speed qualitative filter paper) for 10 seconds, then sandwich it between polytetrafluoroethylene films and use a flat vulcanizer at 80°C Pressurize at 1 MPa and heat for 120 seconds to partially dissolve the surface and fill the pores of the full cellulose paper to ensure that the light refractive index in the thickness direction is almost the same to prepare a partially dissolved full cellulose paper.

[0047] 2) The partially dissolved whole cellulose p...

Embodiment 2

[0060] A method for preparing rollable nano paper-based flexible solar cells by 3D airgel jet precision printing, comprising the following steps and process conditions:

[0061] A) Preparation of flexible paper-based nano-optical paper: using ionic liquid to directly soak the whole cellulose base paper, and then heat-rolled to regenerate and prepare the nano-optical paper substrate, including the following steps:

[0062] 1) Use ionic liquid (N-ethylimidazolium hydrogen phosphite) to soak the whole cellulose paper (double-circle medium-speed qualitative filter paper) for 10 seconds, then sandwich it between polytetrafluoroethylene films and use a flat vulcanizer at 80°C Pressurize at 1 MPa and heat for 30 seconds to partially dissolve the surface and fill pores of the whole cellulose paper to ensure that the light refractive index in the thickness direction is almost the same to prepare a partially dissolved whole cellulose paper.

[0063] 2) The partially dissolved whole cell...

Embodiment 3

[0073] A method for preparing rollable nano paper-based flexible solar cells by 3D airgel jet precision printing, comprising the following steps and process conditions:

[0074] A) Preparation of flexible paper-based nano-optical paper: using ionic liquid to directly soak the whole cellulose base paper, and then heat-rolled to regenerate and prepare the nano-optical paper substrate, including the following steps:

[0075] 1) Use ionic liquid (N-ethylimidazolium hydrogen phosphite) to soak the whole cellulose paper (double-circle medium-speed qualitative filter paper) for 10 seconds, then sandwich it between polytetrafluoroethylene films and use a flat vulcanizer at 80°C Pressurize at 1 MPa and heat for 30 seconds to partially dissolve the surface and fill pores of the whole cellulose paper to ensure that the light refractive index in the thickness direction is almost the same to prepare a partially dissolved whole cellulose paper.

[0076] 2) The partially dissolved whole cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power conversion efficiency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com