Integrated efficient concrete production equipment

A technology for production equipment and concrete, which is applied in the field of integrated high-efficiency concrete production equipment, can solve problems such as dust, time-consuming, and large quantities, and achieve the effects of ensuring environmental protection, improving production efficiency, and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

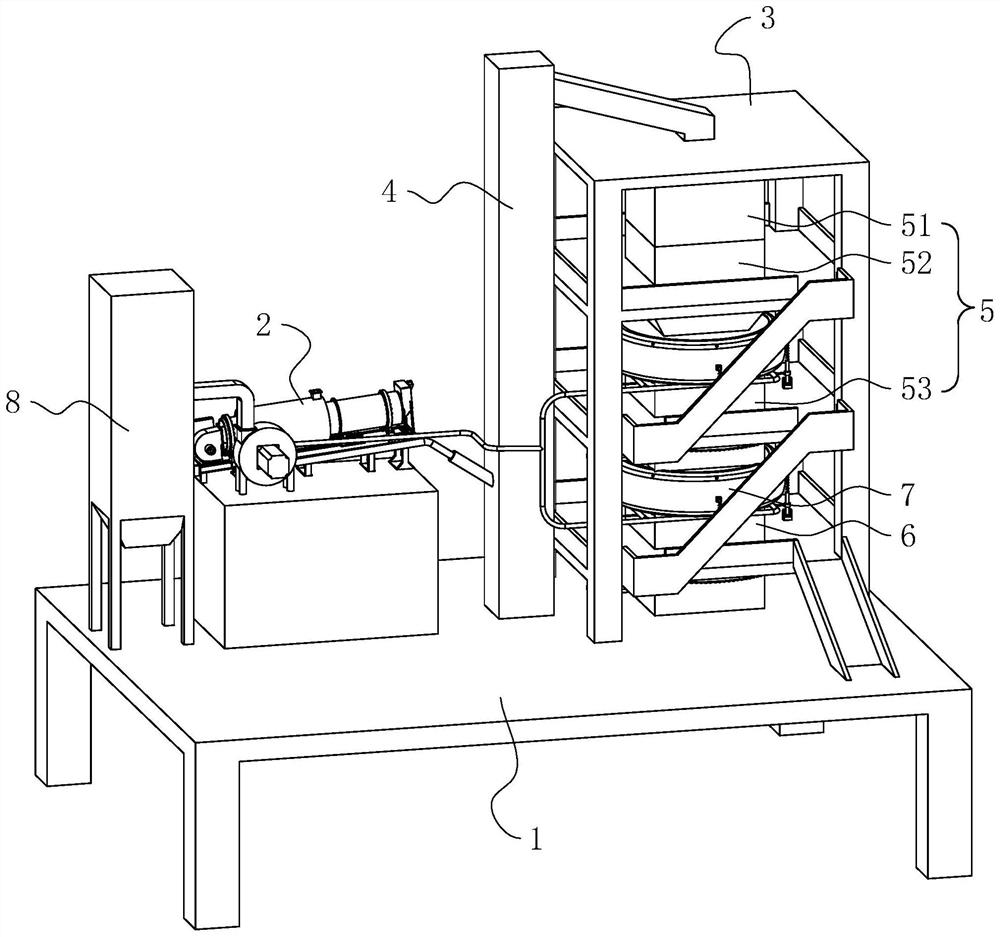

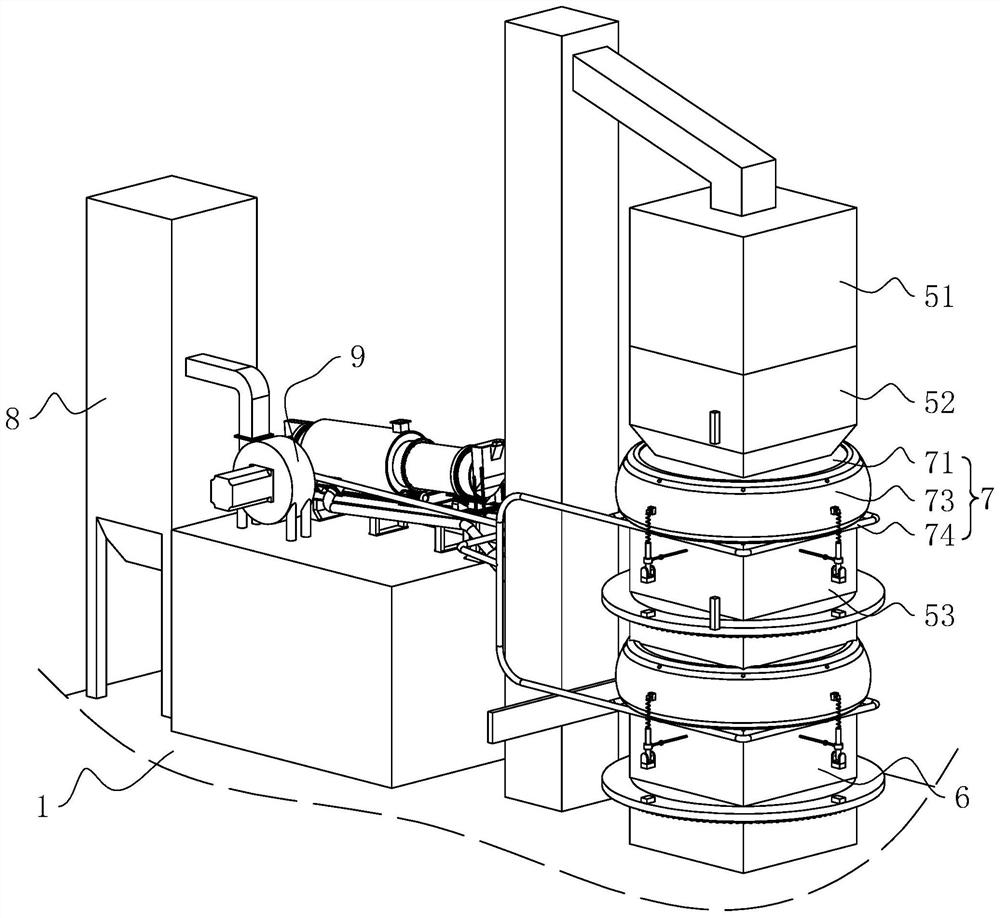

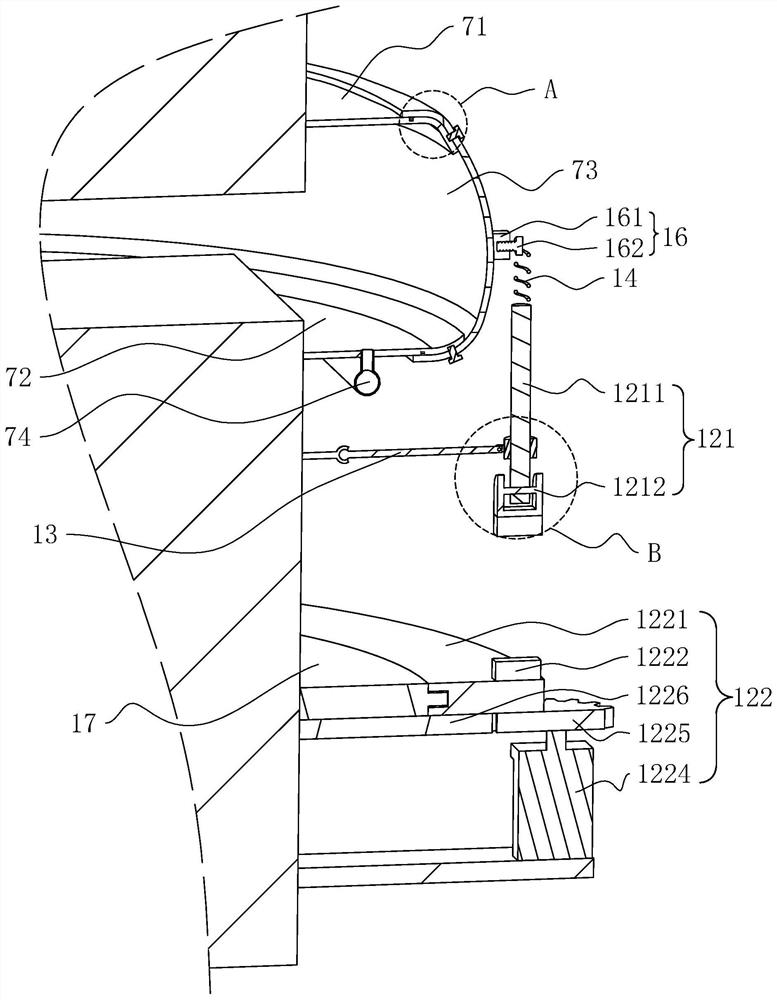

[0034] The following is attached Figure 1-5 The application is described in further detail.

[0035] The embodiment of this application discloses an integrated high-efficiency concrete production equipment, referring to figure 1 , comprising a frame 1, a mixer 2 arranged on the frame 1 and an integrated frame 3, the integrated frame 3 is provided with a lifting mechanism, the discharge port of the mixer 2 is connected with the feed inlet of the lifting mechanism, and the lifting The mechanism can use the elevator 4, and the mixer 2 can heat-treat the raw concrete materials and recycled materials, and the heated materials will enter the elevator 4, and the elevator 4 will transport the materials upwards.

[0036] refer to figure 1 , the integrated frame 3 is provided with a batching mechanism 5, and the batching mechanism 5 includes a screening assembly 51 for screening sand and gravel, a material storage assembly for storing sand and gravel arranged in sequence from top to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap