High-color-purity red light up-conversion nanoparticle material and preparation method thereof

A nanoparticle and color purity technology, applied in the field of high color purity red light up-conversion nanoparticle materials and their preparation, can solve problems such as inability to suppress luminescence quenching, and achieve the effects of reducing surface defects, luminescence enhancement, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

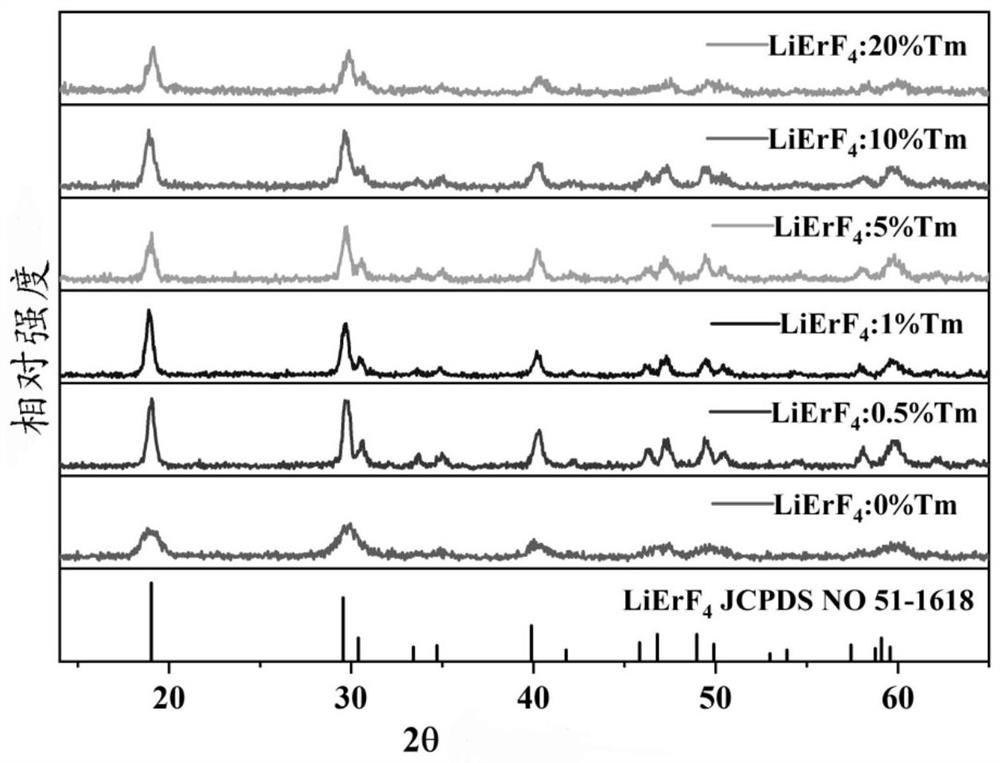

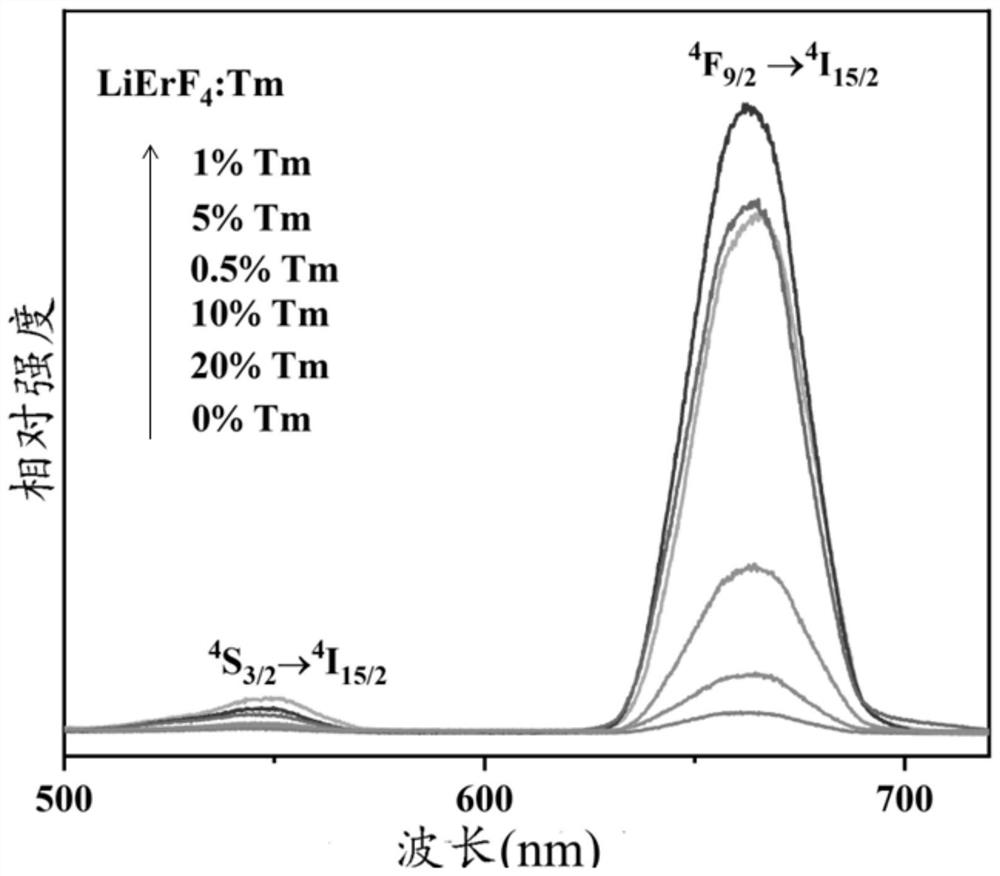

[0034] Example 1: This example is converted from nanoparticle materials on high-color purity red light, and chemical formula is LIERF. 4 : TM 3+ Tm 3+ Doped mole is in turn. 3+ TM 3+ The total molar amount of 0.5%, 1.0%, 5.0%, 10%, 20%;

[0035] TM 3+ The doping concentration is 0.5%, 1.0%, 5.0%, 10%, 20% of Lierf in turn. 4 The preparation method of the nanoparticles are up-converted, and the specific steps are as follows:

[0036] (1) Put ERCL 3 The solution was added to an organic solvent, and the temperature increasing segment was carried out under stirring conditions to obtain a mixed liquid A; wherein the organic solvent is a mixed solvent of oleic acid and octadene; wherein the volume ratio of oleic acid and octadene in the organic solvent is 2: 3, ERCL 3 The volume ratio of the solution to the organic solvent is 1: 10, ERCL 3 The solution concentration is 0.5mol / L; ERCL 3 Solution and TMCL 3 The volume ratio of the solution was 1.99: 0.01, 1.98: 0.02, 1.9: 0.1, 1.8: 0.2 ...

Embodiment 2

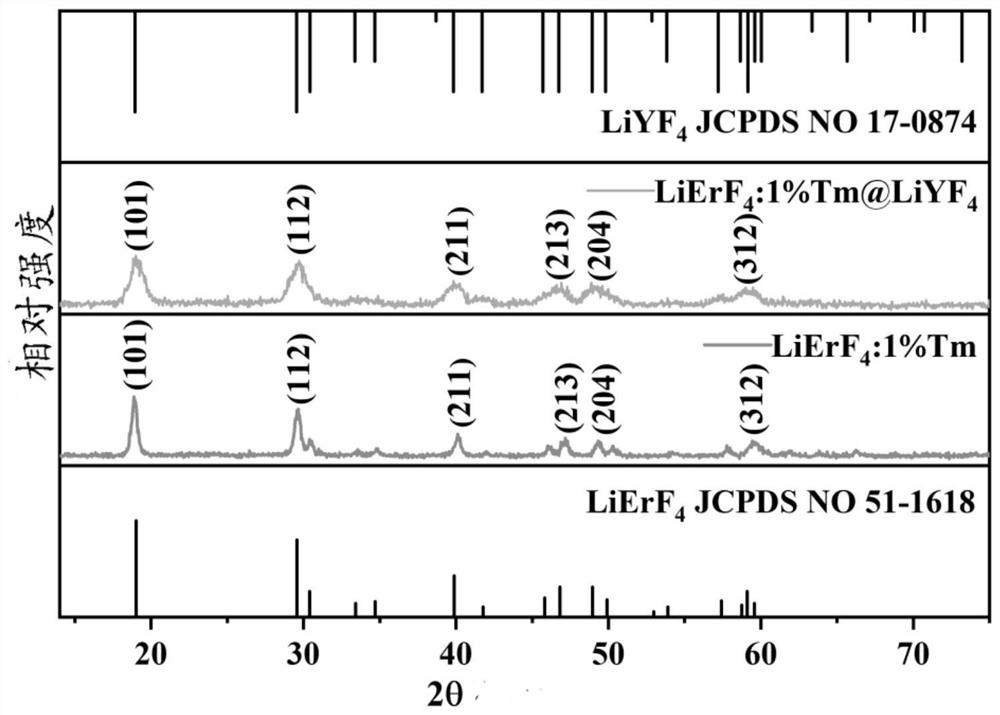

[0041] Example 2: This example high-colored purity red light conversion nanoparticle material, chemical formula is LIERF 4 : TM 3+ @Liyf 4 LIERF 4 : TM 3+ @Liyf 4 LIERF 4 : TM 3+ Like core, LiYf 4 For the shell of the shell structure, Lierf 4 : TM 3+ TM in nanoparticles 3+ Doped mole is ER and TM in turn 3+ The total molar amount of 0.5%, 1.0%, 5.0%, 10.0%, 20.0%;

[0042] TM 3+ The doping concentration is 0.5%, 1.0%, 5.0%, 10.0%, 20.0% of Lierf. 4 : TM 3+ @Liyf 4 The preparation method, the specific steps are as follows:

[0043] (1) Put ERCL 3 The solution was added to an organic solvent, and the temperature increasing segment was carried out under stirring conditions to obtain a mixed liquid A; wherein the organic solvent is a mixed solvent of oleic acid and octadene; wherein the volume ratio of oleic acid and octadene in the organic solvent is 2: 3.2, ERCL 3 The volume ratio of the solution to the organic solvent is 1: 11, ERCL 3 The solution concentration is 0.5mol / L; ERCL ...

Embodiment 3

[0052] Example 3: This example high-colored purity red light conversion nanoparticle material, chemical formula is LIERF 4 : TM 3+ @Liyf 4 LIERF 4 : TM 3+ @Liyf 4 LIERF 4 : TM 3+ Like core, LiYf 4 For the shell of the shell structure, Lierf 4 : TM 3+ TM in nanoparticles 3+ Doped molar amount for ER 3+ TM 3+ 1.0% of the total mole;

[0053] TM 3+ Lierf in doped concentration is 1.0% 4 Upload nanoparticles and lierf 4 : TM 3+ @Liyf 4 The preparation method, the specific steps are as follows:

[0054] (1) Put ERCL 3 Solution and TMCL 3 The solution was added to an organic solvent, and the temperature increasing segment was carried out under stirring conditions to obtain a mixed liquid A; wherein the organic solvent is a mixed solvent of oleic acid and octadene; wherein the volume ratio of oleic acid and octadene in the organic solvent is 2: 3.2, ERCL 3 Solution and TMCL 3 The total volume ratio of the solution and the volume ratio of the organic solvent is 1: 10, ERCL 3 The concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com