Super-lubricating composition based on beta-diketone and cellulose nanocrystals and super-lubricating material

A cellulose and nanocrystalline technology, used in lubricating compositions, base materials, petroleum industry, etc., can solve the problems of poor performance, narrow working conditions, limited bearing capacity, etc., and achieve obvious shear thinning characteristics, wide ultra Slip condition range, the effect of reducing viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

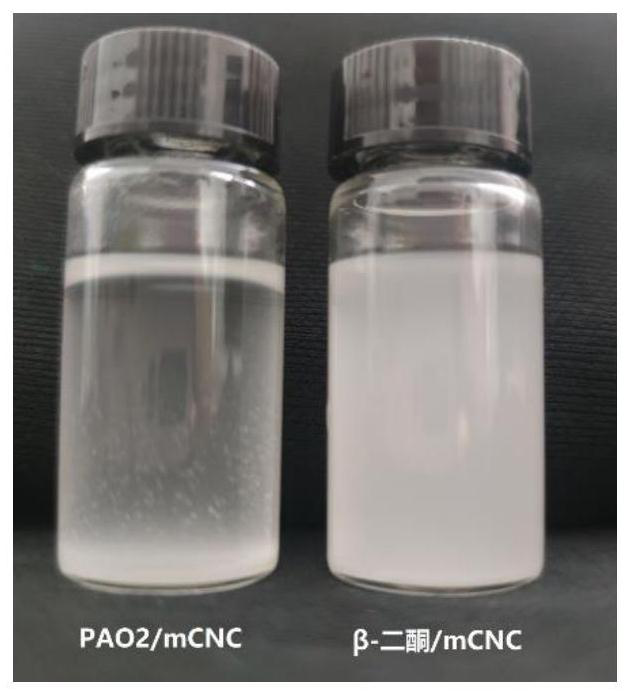

[0039] with R 1 =C 3 h 7 , R 2 =C 5 h 11 The β-diketone is the base oil, with R=C 6 h 11 β-diketone and mCNC were respectively dissolved in amylacetophenone with amyl acetophenone as an additive, and β-diketone and mCNC were respectively dissolved in pentyl acetophenone, and then mixed again, and the solvent was evaporated to obtain uniformly dispersed β-diketone / mCNC Composite oil, wherein the doping amount of mCNC is 0.5wt%. At the same time, the corresponding PAO2 / mCNC composite oil was prepared with the low-viscosity oil PAO2 as the base oil, as a comparative example.

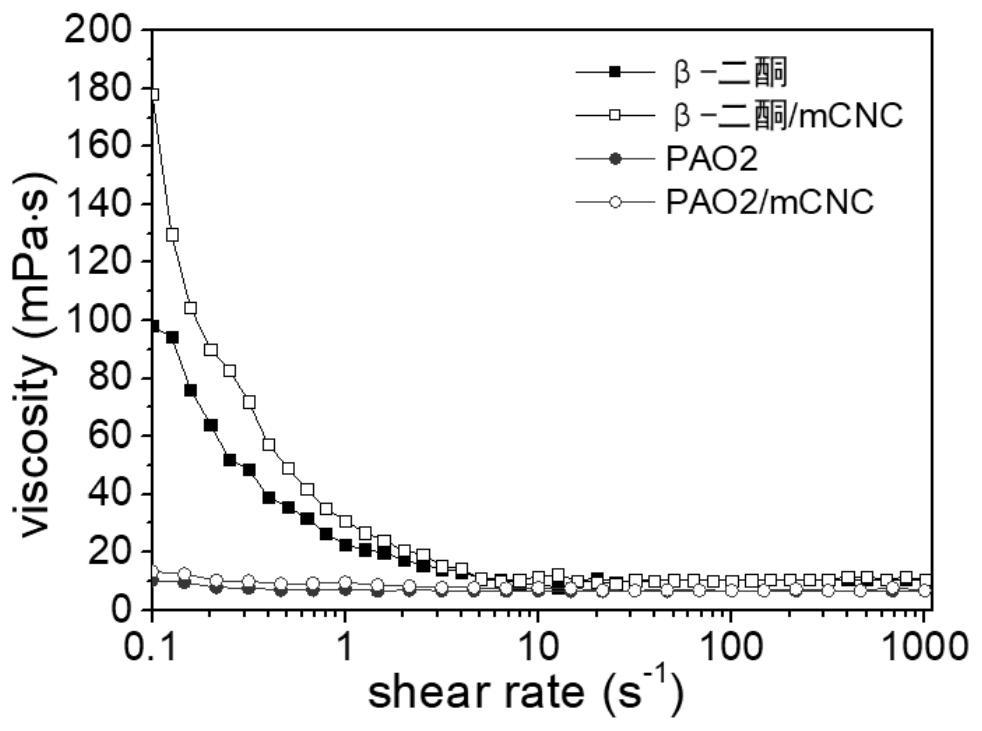

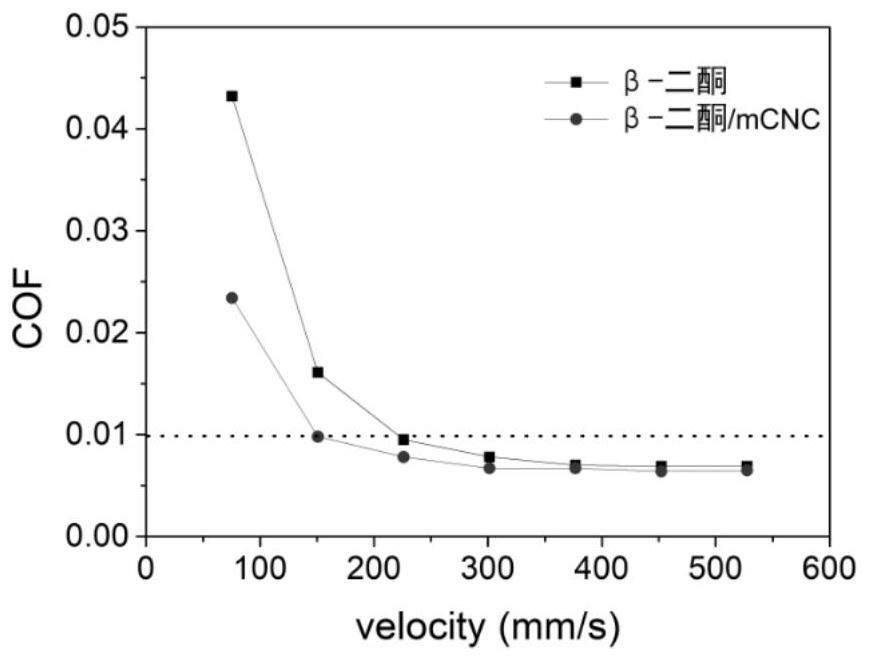

[0040] Rheological tests were performed on β-diketone, β-diketone / mCNC, PAO2 and PAO2 / mCNC with a rotational rheometer, and the results were as follows figure 1As shown, it can be seen that β-diketone has a higher viscosity than PAO2 at a low shear rate. After mCNC is added, the molecular chains grafted on its surface can entangle with β-diketone to form a physically cross-linked network structure ...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is: in the chemical structural formula of the β-diketone adopted, R 1 =R 2 =C 4 h 8 OCH 3 , in the chemical structural formula of mCNC used R=C 4 h 8 OCH 3 . Other steps, reagents and parameters are the same as in Example 1, wherein the content of mCNC is 5wt%.

[0045] The rheological properties of the β-diketone / mCNC prepared in this example were confirmed by a rotational rheometer, and at 0.1s -1 At a certain shear rate, the viscosity of β-diketone can be raised from 90mPa·s to 172mPa·s; -1 Keep the low viscosity of β-diketone 8mPa·s. The dispersion stability of β-diketone / mCNC was confirmed by a 30-day anti-sedimentation test; the super-slip performance of β-diketone / mCNC was confirmed by a multifunctional friction tester. The minimum sliding speed has been expanded from 230mm / s to 160mm / s.

Embodiment 3

[0047] This example differs from Example 1 in that: in the process of doping mCNC into β-diketone, ethyl 2-methylbenzoate is used as the intermediate solvent, and the doping amount of mCNC is 1 wt%. Other steps, reagents and parameters are the same as in Example 1. The rheological properties of the β-diketone / mCNC prepared in this example were confirmed by a rotational rheometer, and at 0.1s -1 At a certain shear rate, the viscosity of β-diketone can be raised from 98mPa·s to 190mPa·s; -1 Keep the low viscosity of β-diketone 8mPa·s. The dispersion stability of β-diketone / mCNC was confirmed by a 30-day anti-sedimentation test; the super-slip performance of β-diketone / mCNC was confirmed by a multifunctional friction tester. The minimum sliding speed has been expanded from 220mm / s to 145mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com