Treatment method of superior molten slag of monazite

A treatment method and a technology for optimizing slag dissolution, which are applied in chemical instruments and methods, improvement of process efficiency, uranium oxide/hydroxide, etc., can solve problems such as complicated process, difficult management, and unsatisfactory separation effect, and achieve waste Less acid discharge, good separation effect, and low raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

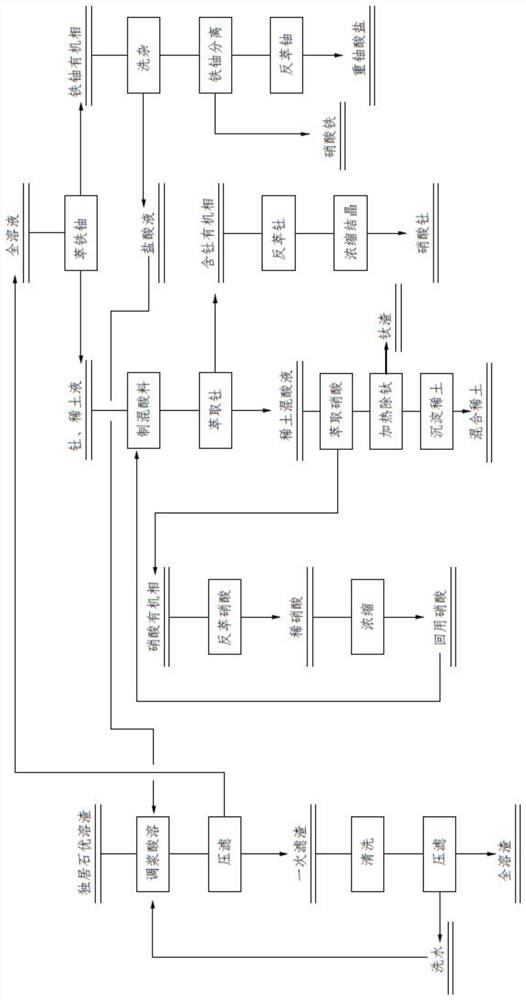

Method used

Image

Examples

Embodiment 1

[0104] Dissolve a certain batch of monazite excellent molten slag (Kg): industrial HCl (L) (about 9.5mol / L) = 1.0:2.0 according to the method of the above-mentioned step (1), and the pulping concentration is 40Be', and it is as listed in Table 1. The complete solution composed of;

[0105] Table 1 Composition of the complete solution obtained from monazite excellent slag dissolution

[0106] components u 3 o 8

[0107] According to the above-mentioned steps (2), with 20% tributyl phosphate (TBP)-kerosene solution as the extractant, the obtained iron-containing and uranium-containing organic phase is washed with 2.5mol / L HCl as the washing liquid; wherein, the iron-uranium extractant : Total solution: cleaning solution ratio=2.0:1.0:0.33, 12 grades in the extraction section, 6 grades in the cleaning section;

[0108] According to above-mentioned steps (3), take 20% tributyl phosphate (TBP)-kerosene solution as extraction agent, 0.25mol / LHNO 3 For washing iron,...

Embodiment 2

[0116] Monazite rare earth excellent molten slag (Kg): industrial HCl (L) (about 9.5mol / L)=1.0:2.0 (L) is dissolved excellent molten slag according to the method for above-mentioned step (1), and the mixing concentration is 45Be ', Properly controlling the dilution volume can obtain a higher concentration of the whole solution. Its composition is listed in Table 4.

[0117] Table 4 Composition of the complete solution obtained from monazite excellent melting slag

[0118] components u 3 o 8

THO 2

REO Fe 2 o 3

HCl Concentration(g / L) 3.5 62 40 8 2.5N

[0119] According to the above steps (2), with 20% dimethylheptyl methylphosphate (P-350)-kerosene solution as the extractant, the obtained iron-containing and uranium-containing organic phase uses 2.5mol / L HCl as the washing liquid; Agent: full solution: washing liquid = 2.0:1.0:0.33, 12 stages in the extraction section, 6 stages in the washing section;

[0120] According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com