Spinning collecting equipment capable of achieving direct weaving and fiber weaving method

A collection equipment and fiber weaving technology, which is applied in the field of fiber manufacturing, can solve the problems of low efficiency and no universal device, etc., and achieve the effect of strong versatility and high-efficiency weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

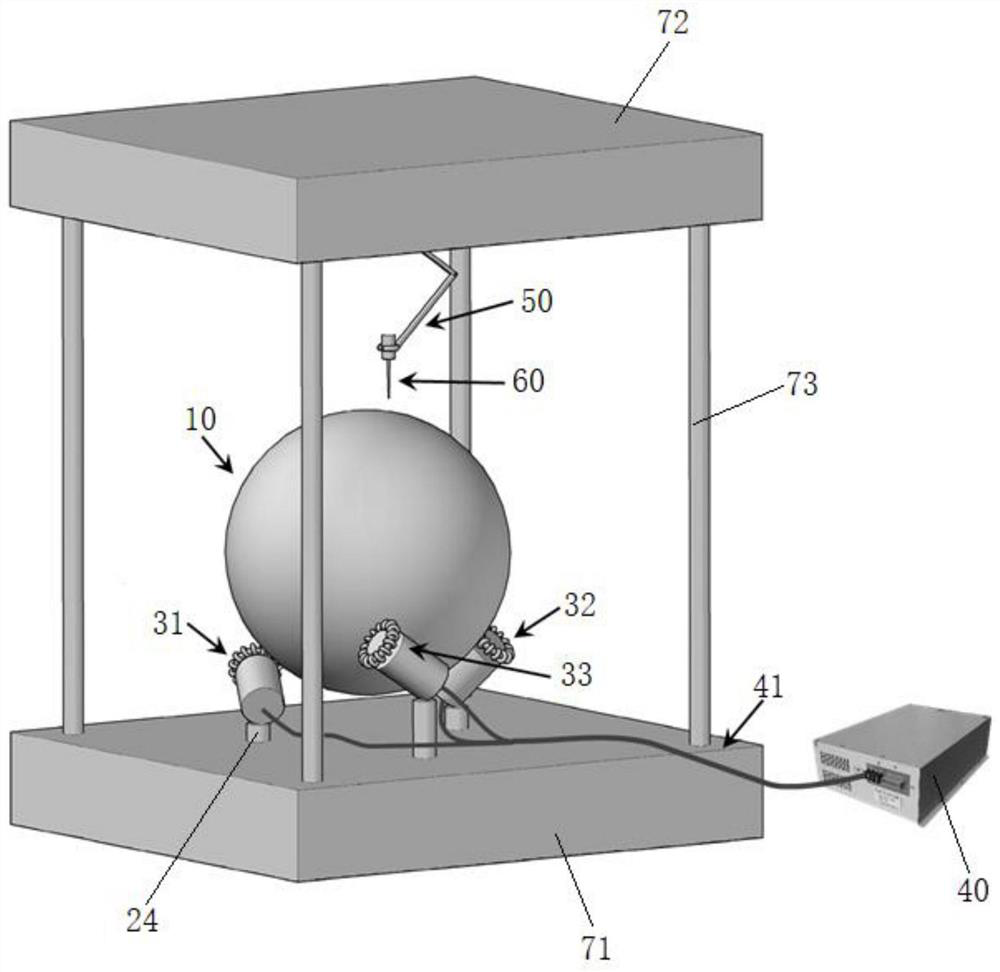

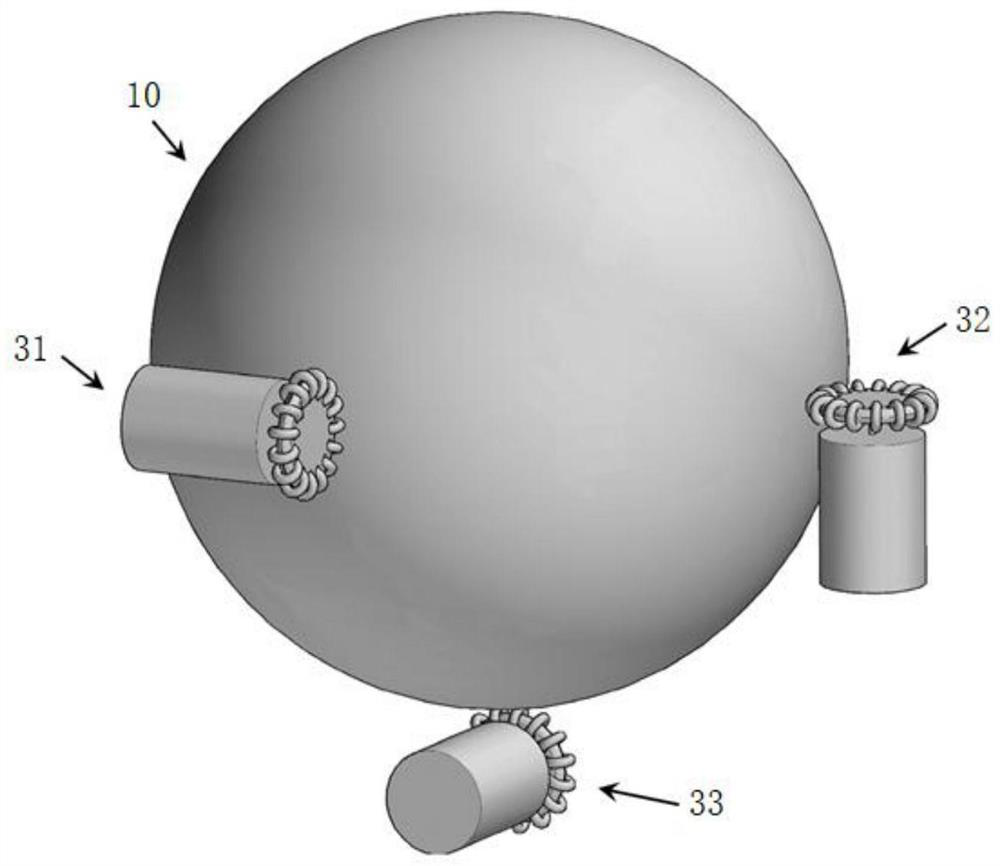

[0041] Such as Figure 4 As shown, in this embodiment, the spinning and collecting equipment that can be directly woven is used for dry spinning to obtain acetate fibers with a "cross" weaving structure.

[0042] S1. Dissolve diacetate in acetone solution, and keep stirring at a high speed in a constant temperature water bath at 30°C;

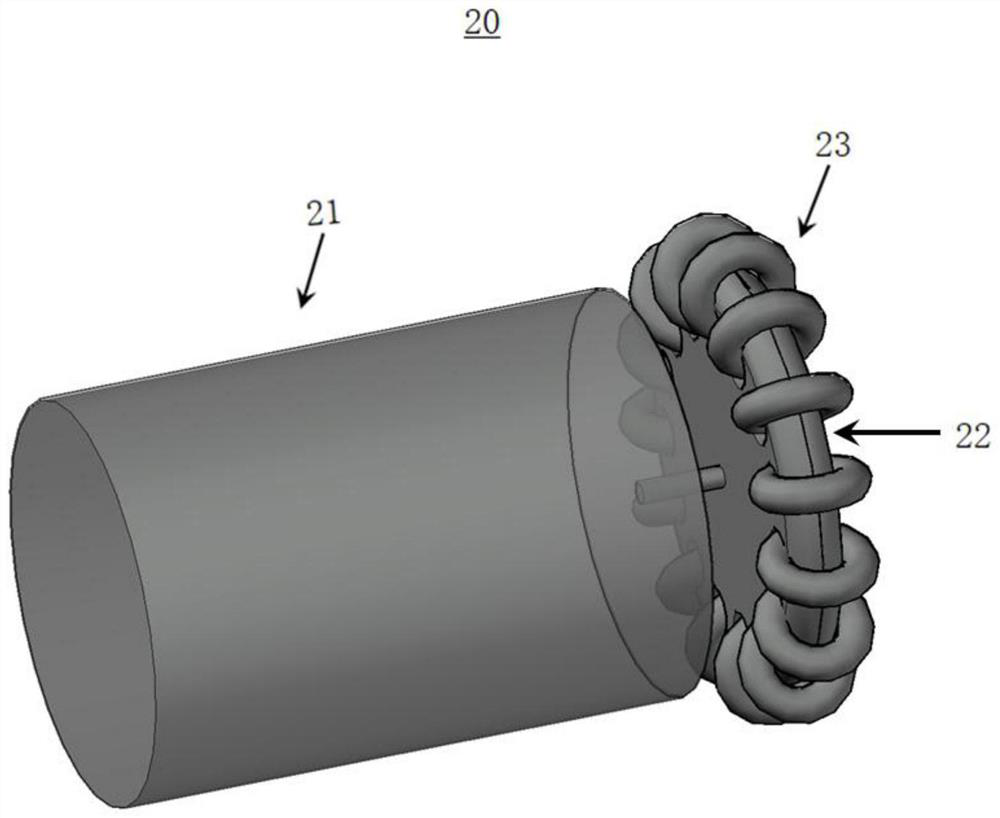

[0043] S2. Adjust the upper support arm 50 so that the spinning needle 60 is 20cm away from the top of the collection ball 10; set the speed program of the drive wheel 20, first the drive wheel 20X rotates at 90° / s for 16s, so that the collection ball 10 rotates one circle on the Y-Z plane, Then the driving wheel 20Y rotates at 90° / s for 16s, so that the collecting ball 10 rotates one circle in the X-Z plane, completes a cycle, and runs cyclically with this program;

[0044] S3. use the peristaltic constant flow pump 80 to draw the mixed solution to the spinning needle 60, and extrude from the needle, the solvent acetone in the spinning soluti...

Embodiment 2

[0046] Such as Figure 5 As shown, in this embodiment, blow spinning is performed using a spinning collection device that can be directly woven to obtain polyvinylpyrrolidone nanofibers with a "cross" weaving structure.

[0047] 1. Dissolve polyvinylpyrrolidone in the aqueous solution and keep stirring at a high speed in a constant temperature water bath at 30°C;

[0048] 2. Adjust the upper support arm 50 so that the spinning needle 60 is 20cm away from the top of the collection ball 10; set the speed program of the driving wheel 20, firstly the driving wheel 20X rotates at 360° / s for 4s, so that the collection ball 10 rotates one circle on the Y-Z plane, Then the driving wheel 20Y rotates at 360° / s for 4s, so that the collecting ball 10 rotates once in the X-Z plane, completes a cycle, and runs in this program cycle;

[0049] 3. Use the peristaltic constant flow pump 80 to pump the mixed solution to the spinning needle 60, turn on the high-pressure air pump 90, the high-spe...

Embodiment 3

[0051] Such as Figure 6 As shown, in this example, a spinning and collecting device that can be directly woven is used for electrospinning to obtain silica nanofibers with a "cross" weaving structure.

[0052] 1. Mix tetraethyl orthosilicate with the aqueous solution, hydrolyze it for 6 hours, add it to the beaker of the constant temperature water bath, then add 3% polyethylene oxide to dissolve, and keep stirring at a high speed in the constant temperature water bath at 30°C;

[0053] 2. Adjust the upper support arm 50 so that the spinning needle 60 is 10cm away from the top of the collection ball 10; the collection ball 10 is wrapped with a layer of aluminum foil paper, and the speed program of the driving wheel 20 is set. First, the driving wheel 20X rotates at 360° / s for 4s, Make the collection ball 10 rotate one circle on the Y-Z plane, then the driving wheel 20Y rotates at 360° / s for 4s, make the collection ball 10 rotate one circle on the X-Z plane, complete one cycle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com