Fusing hollowed-out fabric and preparation method thereof

A kind of fabric and melting technology, which is applied in the direction of improved hand feeling fiber, fiber type, textile decoration, etc., can solve the problems of physical properties such as fabric tearing strength and snagging, and the hollowing can not be too small, etc., to improve wear Performance and comfort, easy care, comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

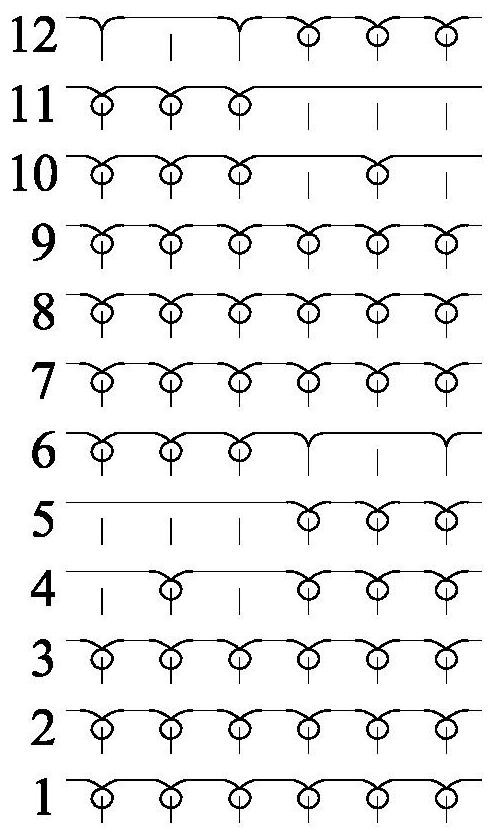

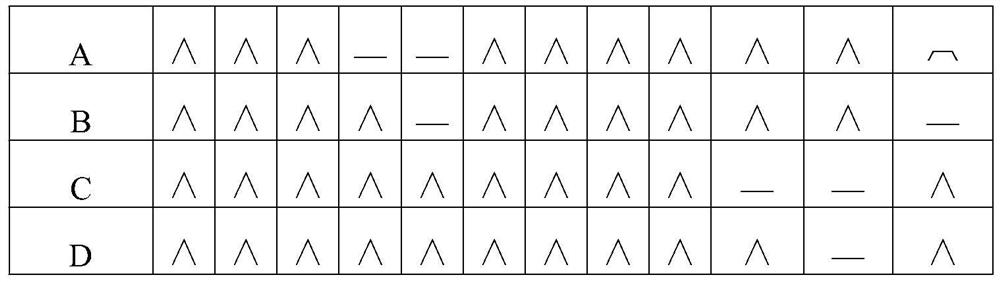

[0026] A melt-off hollow fabric, composed of soluble yarns and insoluble yarns, the melt-break hollow fabric includes several hollow areas obtained by dissolving and removing soluble yarns, each hollow area includes 5 circular hollows, and the The area of the hollow area is 1.2mm 2 .

[0027] As a preferred embodiment, the soluble yarn is blended yarn of polyester fiber and soluble vinylon fiber; the insoluble yarn is pure cotton of JC21-60S. The count of the soluble yarn accounts for 30% of the count of the insoluble yarn. The area of the hollow area accounts for 0.9% of the whole fabric. The mass ratio of the soluble yarn to the insoluble yarn is 2:100. The grammage of the melted hollow fabric is 100g / m 2 .

[0028] The preparation method of the above-mentioned melting hollow fabric comprises the following steps:

[0029] S1: Select insoluble yarns and soluble yarns as raw materials, in which insoluble yarns account for 85% of the total, and soluble yarns account f...

Embodiment 2

[0034] A melt-off hollow fabric, formed by soluble yarns and insoluble yarns, the melt-break hollow fabric includes several hollow areas obtained by dissolving and removing soluble yarns, each hollow area includes 7 circular hollows, and the The area of the hollow area is 1.3mm 2 .

[0035] As a preferred embodiment, the soluble yarn is selected from 45S soluble vinylon yarn; the insoluble yarn is selected from 150D / 96F DTY polyester filament. The count of the soluble yarn is 65% of the count of the insoluble yarn. The area of the hollow area accounts for 1.5% of the whole fabric.

[0036] The preparation method of the above-mentioned melting hollow fabric comprises the following steps:

[0037] S1: Select insoluble yarns and soluble yarns as raw materials, in which insoluble yarns account for 90% of the total, and soluble yarns account for 10% of the total;

[0038] S2: Based on plain weft knitting, a single-sided circular weft machine with a gauge of 24 needles / inch ...

Embodiment 3

[0046] A melt-off hollow fabric, composed of soluble yarns and insoluble yarns, the melt-break hollow fabric includes several hollow areas obtained by dissolving and removing soluble yarns, each hollow area includes 8 circular hollows, and the The area of the hollow area is 1.5mm 2 .

[0047] As a preferred embodiment, the soluble yarn is selected from 45S soluble vinylon yarn; the insoluble yarn is selected from JC21-60S pure cotton. The count of the soluble yarn accounts for 95% of the count of the insoluble yarn. The area of the hollow area accounts for 1.8% of the whole fabric. The mass ratio of the soluble yarn to the insoluble yarn is 7:100. The grammage of the melted hollow fabric is 150g / m 2 .

[0048] The preparation method of the above-mentioned melting hollow fabric comprises the following steps:

[0049] S1: Select insoluble yarn and soluble yarn as raw materials, in which insoluble yarn accounts for 95% of the total amount, and soluble yarn accounts for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com