Reinforced concrete beam-column joint structure using prestressed steel strands for reinforcement and construction method therefor

A technology of prestressed steel strands and reinforced concrete beams, which is applied in building construction, building maintenance, and construction, and can solve problems such as ineffective prestressing effects, affecting energy dissipation and vibration reduction effects, and weakening of beam and column sections. , to achieve the effect of strengthening the core area of the joint, reducing human and financial resources, and enhancing the stiffness of the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

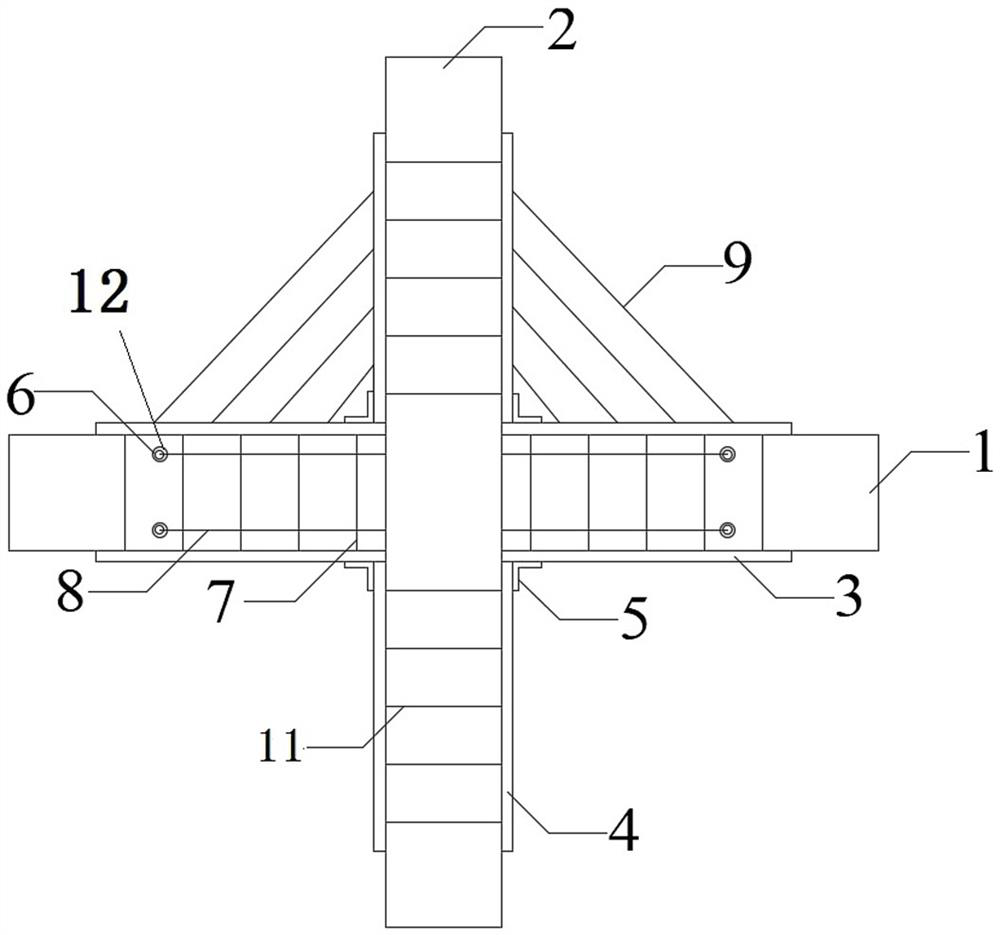

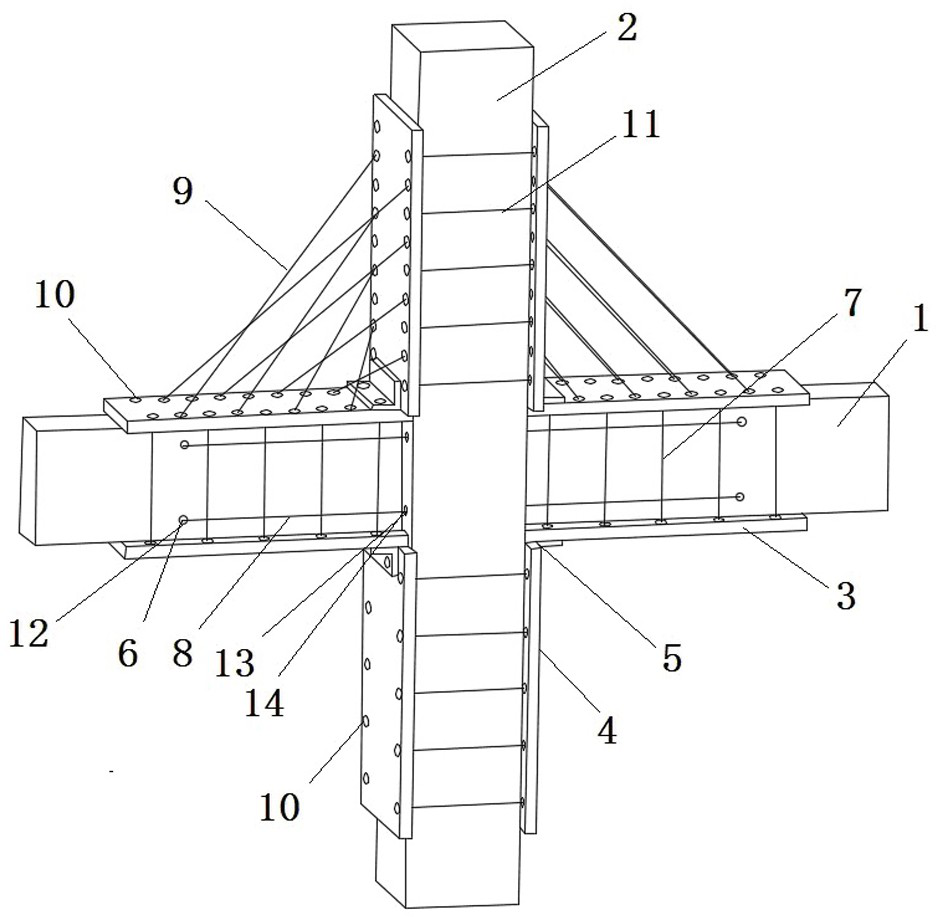

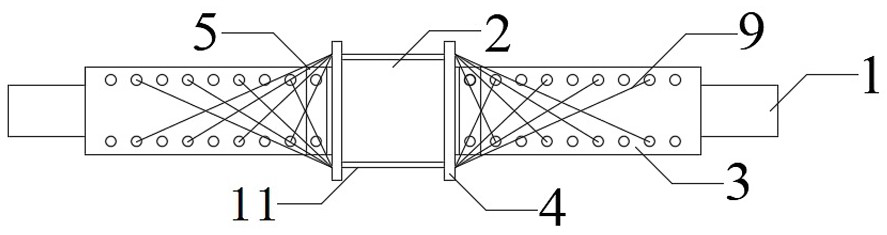

[0029] The prestressed steel strand reinforced reinforced concrete beam-column node structure of the present invention includes reinforced concrete beams 1 and reinforced concrete columns 2 connected horizontally and vertically and vertically, and the upper surface and the lower surface of the reinforced concrete beam 1 are respectively connected with a joint wider than the Beam end steel plate 3 of reinforced concrete beam width (the width here refers to figure 1 The width of the inside of the paper surface), the left and right sides of the reinforced concrete column are respectively connected with column end steel plates 4 wider than the width of the reinforced concrete column (the width here refers to the figure 1 The width of the inside of the paper surface), the steel plate at the beam end and the steel plate at the column end are provided with perforations 10 at positions protruding from the width of the beam or column, and each steel plate is provided with two rows of pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com