Combined anti-cracking and anti-falling external wall insulation board and forming process thereof

An external wall insulation board and anti-cracking technology, which is applied in the field of concrete pouring, can solve the problems of foamed cement boards with many joints, low strength, and danger, and achieve good external wall insulation, strong mechanical fixation, and prevent falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

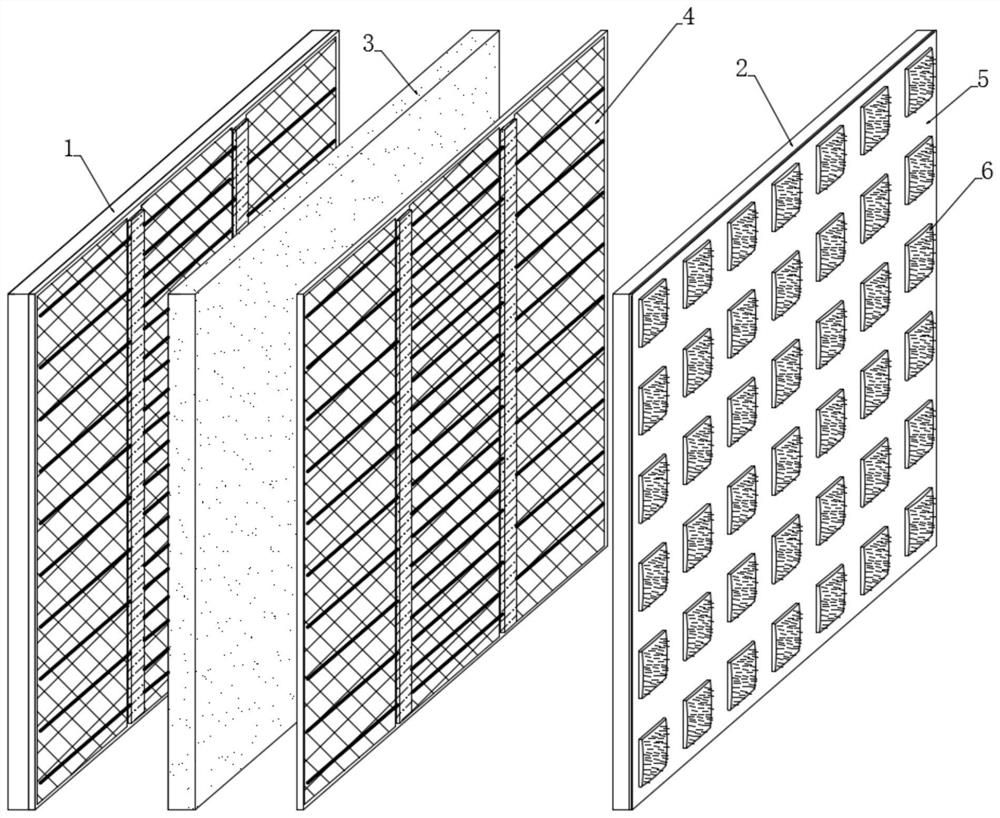

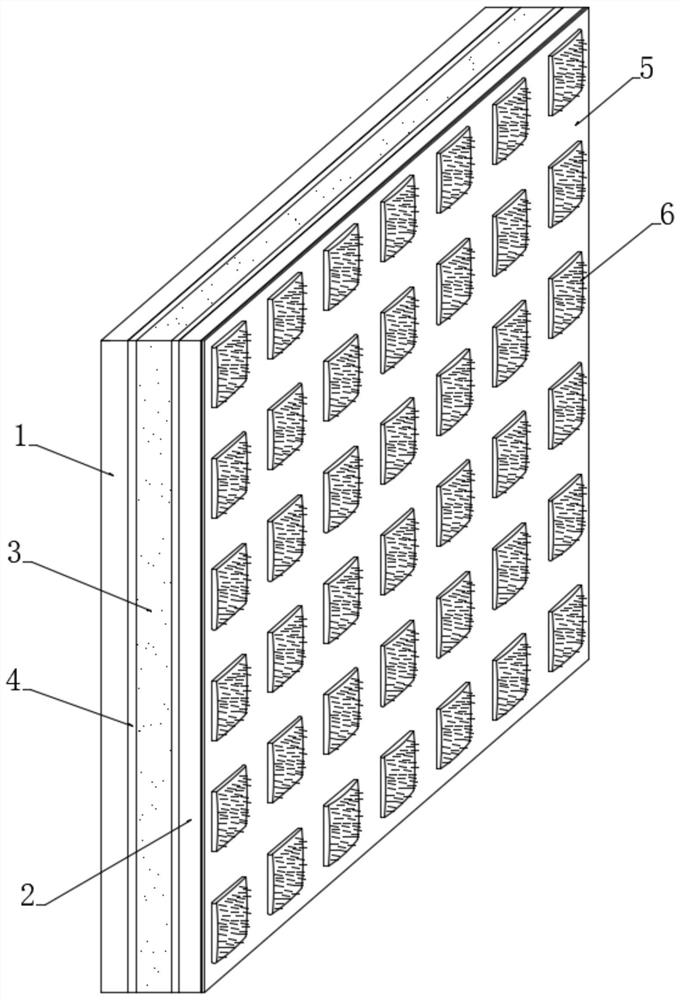

[0039] see Figure 1-2 , a combined anti-cracking and falling-off exterior wall insulation board, comprising a foamed concrete board 1 and an expanded polystyrene board 2, a foamed insulation board 3 is bonded between the foamed concrete board 1 and the expanded polystyrene board 2, and the foamed The left and right ends of the insulation board 3 are attached with a glass fiber bonded mesh layer 4, and the outer end faces of a pair of glass fiber bonded mesh layers 4 are respectively connected to the opposite end faces of the foamed concrete plate 1 and the expanded polystyrene plate 2.

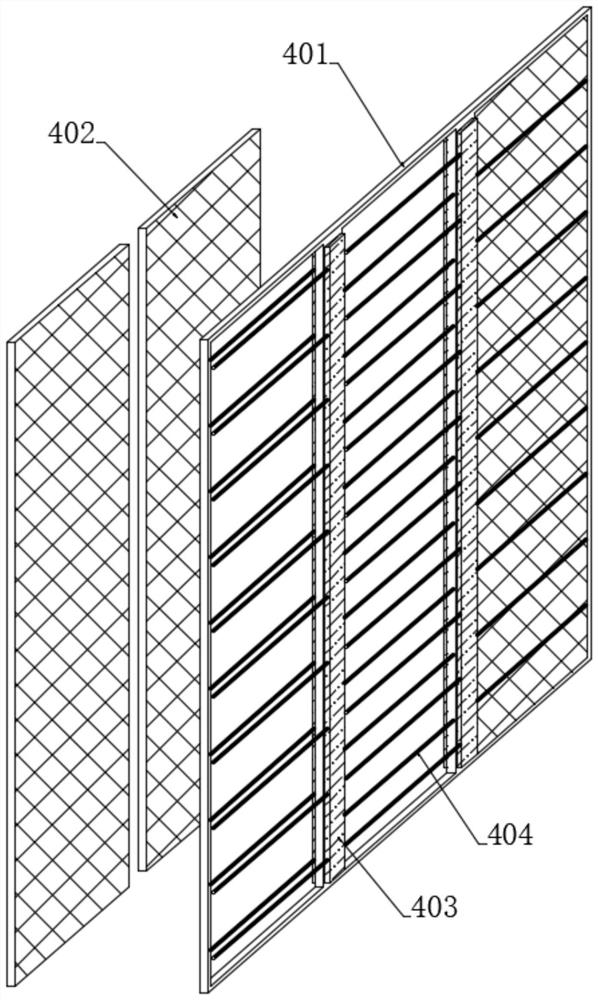

[0040] see Figure 3-4 Specifically, the glass fiber bonding mesh layer 4 includes a positioning frame 401, and a plurality of alkali-resistant glass fiber mesh cloths 402 are embedded and installed on the positioning frame 401. Between two adjacent alkali-resistant glass fiber mesh cloths 402 A polymeric adhesive strip 403 is provided, and the polymeric adhesive strip 403 is also embedded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com