Sewage evaporative air cooler

An evaporative and air cooler technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as waste of fresh water resources, reduce scaling, reduce adhesion, and improve flushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

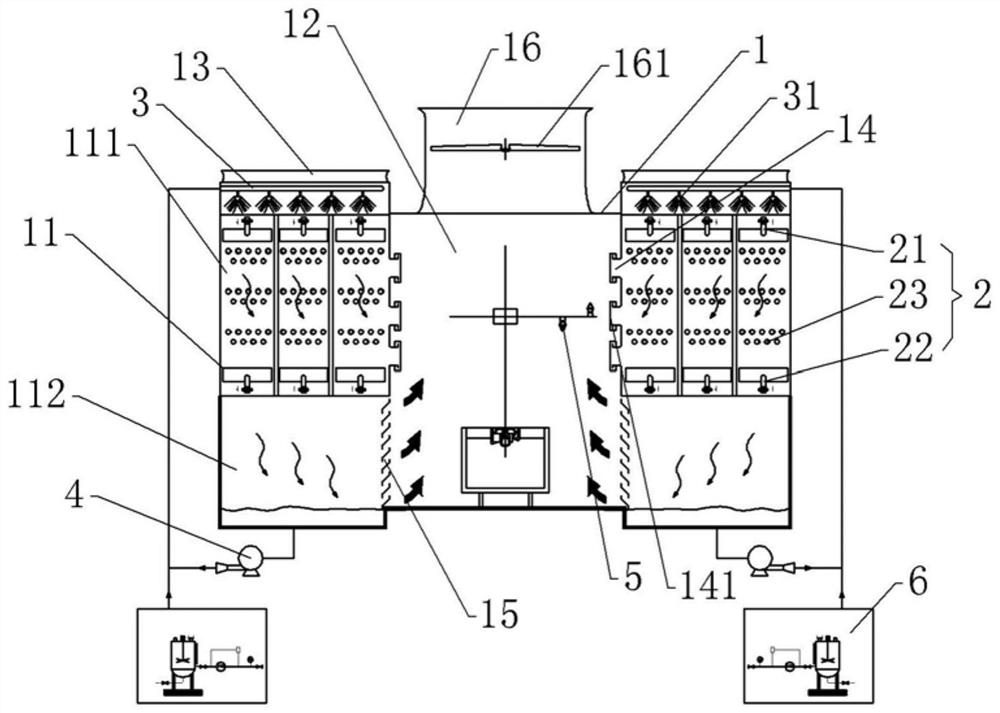

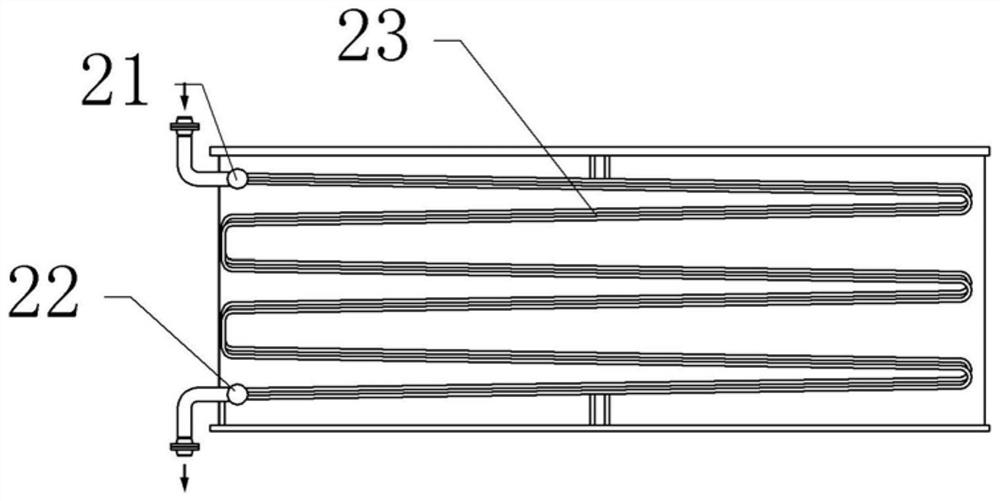

[0042] Sewage evaporative air cooler, basically as attached figure 1 As shown, the device body 1 is included, and the device body 1 is provided with two cooling parts 11 and an air duct 12 between the two cooling parts 11. The top of the device body 1 is provided with an air outlet 16 communicating with the air duct 12. An impeller 161 is disposed inside the air outlet 16 . The cooling part 11 includes an upper cooling layer 111 and a lower collecting layer 112, the cooling layer 111 and the collecting layer 112 are in communication, the cooling layer 111 is isolated from the air duct 12, and multiple sets of heat exchange coils 2 are arranged in the cooling layer 111, In this embodiment, three sets of heat exchange coils 2 arranged horizontally are provided, and the three sets of heat exchange coils 2 are all independently arranged. combine figure 2 As shown, the heat exchange coil 2 includes a medium inlet 21 , a small coil 23 and a medium outlet 22 sequentially arranged ...

Embodiment 2

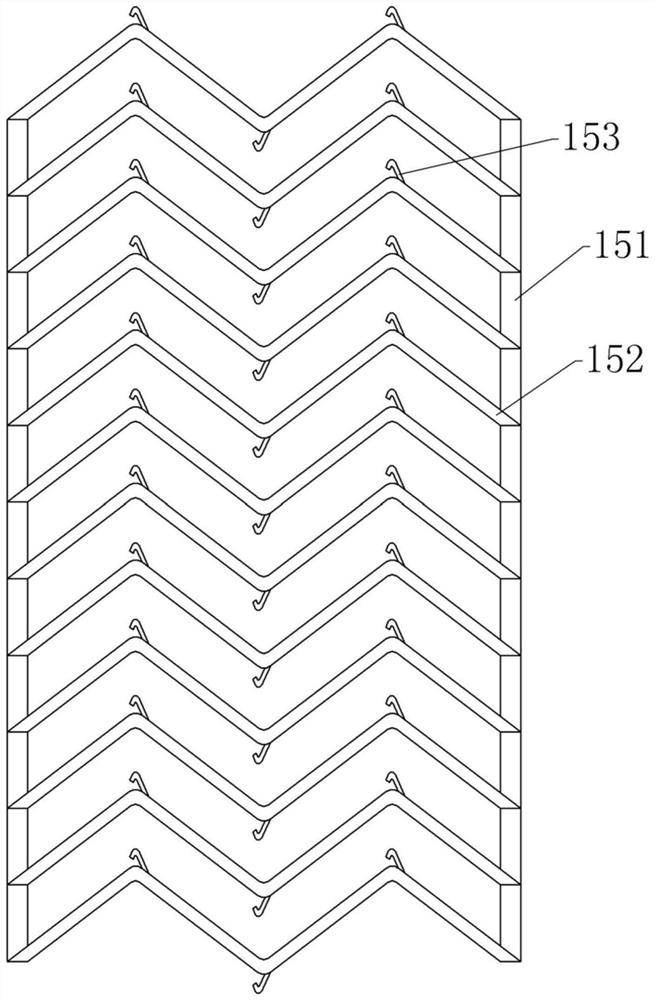

[0059] Embodiment 2 differs from Embodiment 1 only in that, as Figure 4 As shown, in the present embodiment, a filtering device is provided in the collecting layer 112, and the filtering device includes a rotating shaft 8 arranged on the collecting layer 112, and the rotating shaft 8 is provided with a guide flow channel 81, and the guide flow channel 81 communicates with the outside, and guides The flow channel is tapered, and the large diameter end of the flow guide channel communicates with the outside.

[0060] The rotating shaft 8 runs through the rear side of the collecting layer 112 , and the rotating shaft 8 is connected to the collecting layer 112 in rotation. A plurality of collecting plates 9 are evenly distributed on the outer wall of the rotating shaft 8 , and the number of collecting plates 9 can be selected according to actual requirements. In this embodiment, five collecting plates 9 are provided. The collecting plates 9 all include a U-shaped plate body 91 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com