Optical trap-based particle shape and surface roughness detection device and method

A surface roughness and detection device technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficult to achieve high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

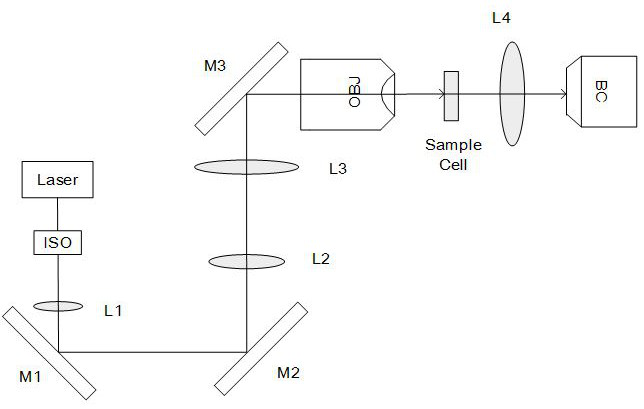

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

[0024] refer to figure 1 , a high-sensitivity optical trap measurement device, including three modules: a particle input module, an optical trap capture module, and an optical field detection module;

[0025] When it is necessary to detect particles, first turn on the optical trap capture module, collimate and focus the light beam, so that the initial captured light can form the optical trap balance point. After completing the preparations above, you can open the particle input module, transport the particles to be detected to the optical trap capture area, use the optical trap capture module to stably capture the particles at the balance point of the optical trap, and then open the light field detection module, use the collimation The lens collects light scattered by the particle, thereby obtaining information on the shape and surface roughness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com