An automatic temperature control tool for optomechanical detection and its use method

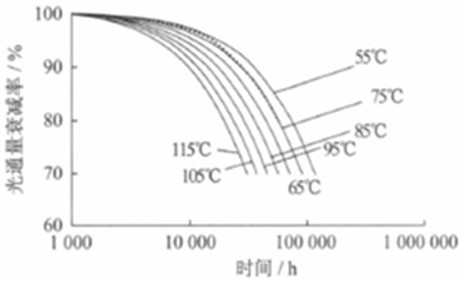

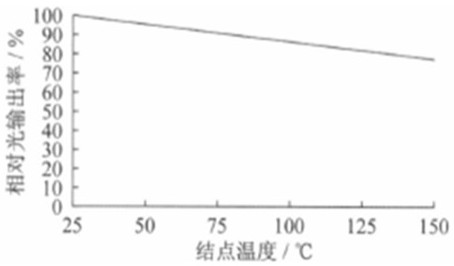

An automatic temperature control and optical-mechanical technology, applied in measuring devices, optical instrument testing, machine/structural component testing, etc., can solve problems such as maintaining the normal and stable temperature of the light source, so as to improve the output of optical-mechanical products and ensure the quality of optical-mechanical products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

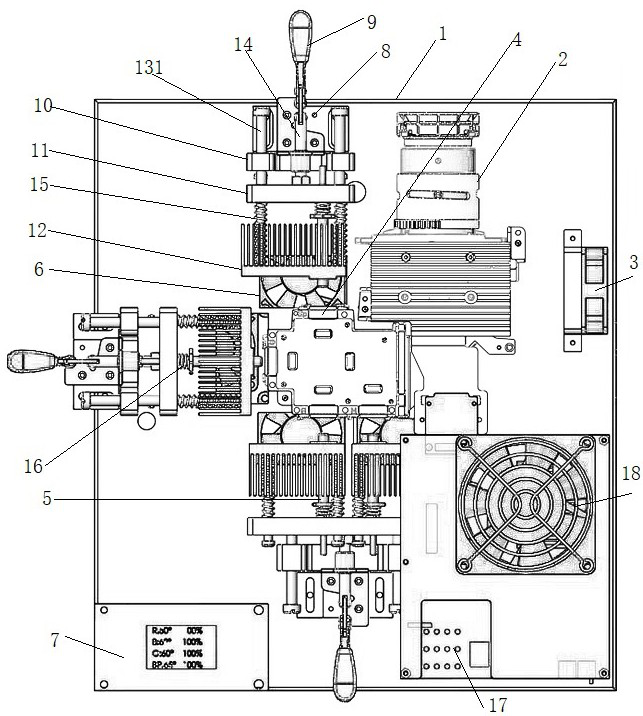

[0034] like Figure 3~4 As shown, an automatic temperature control tool for optomechanical detection includes a stage 1, an optomechanical 2, an optomechanical drive unit, and an optomechanical cooling fan 3. The optomechanical 2 has a plurality of LED light sources 4, and a plurality of A temperature control unit is arranged on the outside of the LED light source 4, and the temperature control unit includes a temperature measuring frame, a temperature sensor 5, a cooling fan 6 and a temperature control module 7, and the temperature sensor 5 is arranged on the temperature measuring frame. The probe of the temperature sensor 5 is in contact with the copper substrate of the LED light source 4 during measurement, the temperature sensor 5 is connected to the input end of the temperature control module through a signal line, and the cooling fan 6 is connected to the output of the temperature control module. The terminals are connected by signal lines.

[0035] Specifically, the te...

Embodiment 2

[0040] like Figure 3~4 As shown, an automatic temperature control tool for optomechanical detection includes a stage 1, an optomechanical 2, an optomechanical drive unit, and an optomechanical cooling fan 3. The optomechanical 2 has a plurality of LED light sources 4, and a plurality of A temperature control unit is arranged on the outside of the LED light source 4, and the temperature control unit includes a temperature measuring frame, a temperature sensor 5, a cooling fan 6 and a temperature control module 7, and the temperature sensor 5 is arranged on the temperature measuring frame. The probe of the temperature sensor 5 is in contact with the copper substrate of the LED light source 4 during measurement, the temperature sensor 5 is connected to the input end of the temperature control module through a signal line, and the cooling fan 6 is connected to the output of the temperature control module. The terminals are connected by signal lines.

[0041] Specifically, the te...

Embodiment 3

[0051] like Figure 6~7 As shown, the difference between the automatic temperature control tooling for optical-mechanical detection in this embodiment of the present invention and Embodiments 1 and 2 is that the temperature control module reads R / G / B / BP respectively through four DS18B20 temperature sensors. Based on the temperature of the backplane of the light source, the cooling fans corresponding to R / G / B / BP are controlled respectively based on the temperature, and then the exhaust air volume is controlled to control the temperature of the backplane of the light source transmitted on the copper block of the tooling, and finally the backplane of the light source is stabilized. Temperature purpose (for example: R temperature 52°C±3, G temperature 62°C±3, B temperature 58°C±3, BP temperature 65°C±3). In order to facilitate the operation of workers, indicator lights of different colors relative to the light source and a TFT liquid crystal temperature display are added to the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com