Test device for simulating collision friction between water stop material and ice and test method thereof

A water-stop material and test device technology, which is applied in the direction of measuring devices, analyzing materials, and using repeated force/pulsation force to test the strength of materials, etc., can solve the problems of ineffective control of friction rate, impact strength, inconvenient operation, etc., and achieve weight Lightweight, easy to operate, and not easy to accumulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

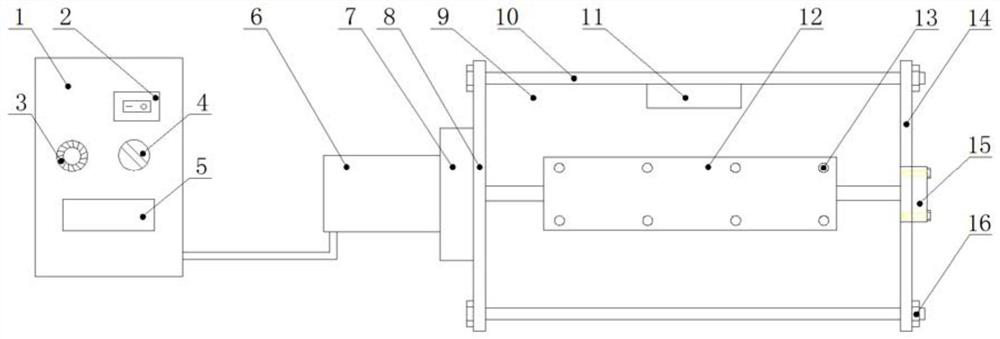

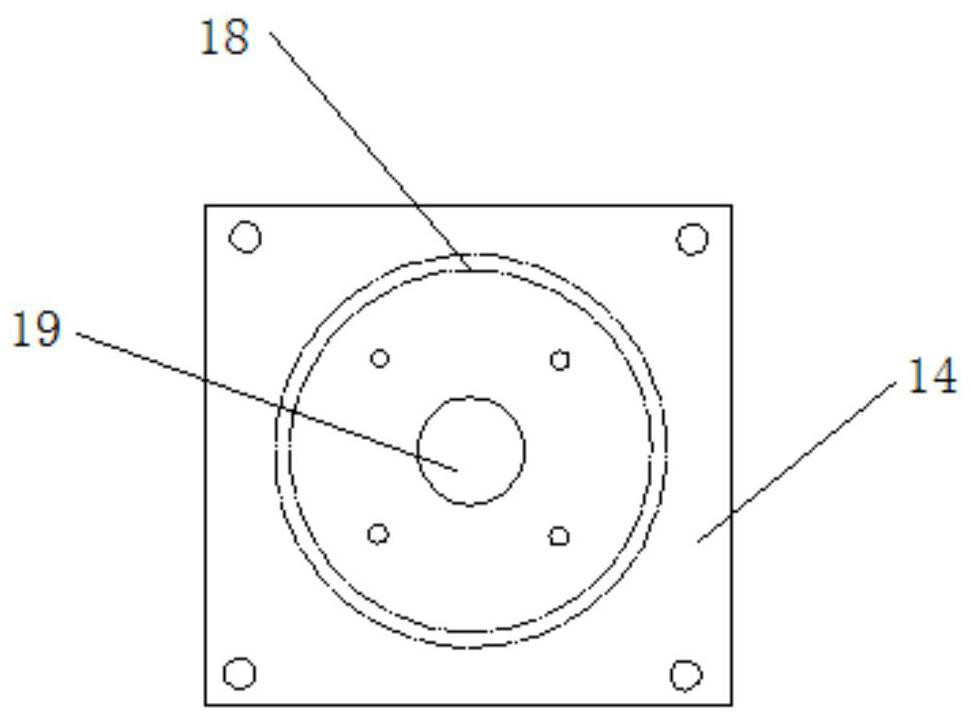

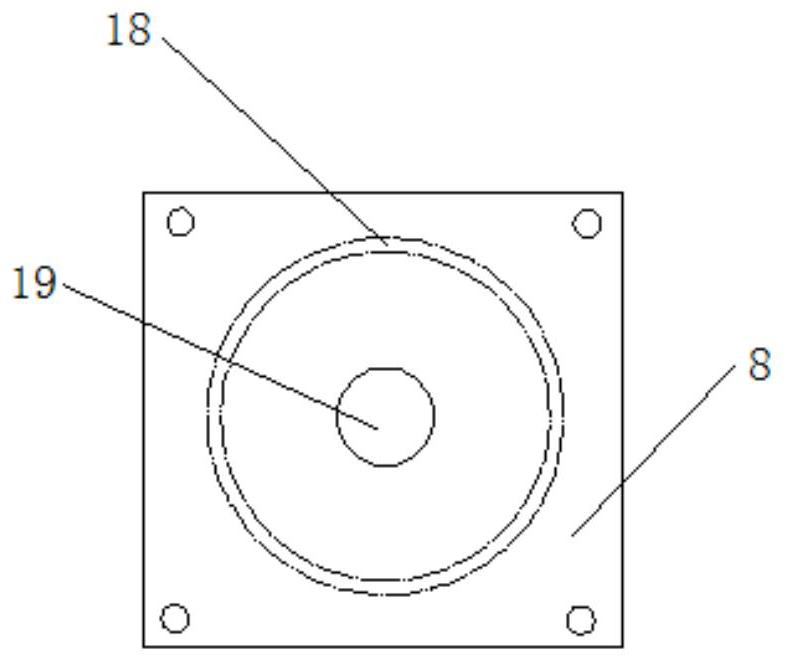

[0035] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, a test device for simulating the collision and friction between water-stop materials and ice includes a control box 1, a switch 2, a steering adjustment knob 3, a speed adjustment knob 4, a speed display screen 5, a stepping motor 6, a bearing seat 7, Top plate 8, plexiglass cylinder 9, multiple screw rods 10, window cover 11, sample rotating shaft 12, bolts 13, bottom plate 14, bottom cover 15 and multiple nuts 16, switch 2, steering adjustment knob 3, rotation speed adjustment knob 4 and the speed display screen 5 are installed on the control box 1, the stepper motor 6 is installed on one side of the control box 1 and connected with the control box 1 by wires, the top plate 8 and the bottom plate 14 are oppositely arranged, the organic glass cylinder 9 is placed horizontally, and the top plate 8 and the bottom plate 14 are sealed and mounted on the two ends of the plexiglass...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination figure 1 The present embodiment will be described. The waterproof material to be tested in this embodiment is a rubber material. This setting is convenient for the real simulation of the actual water-stop material. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 Describe this embodiment, the window cover 11 of this embodiment can be opened and installed on the plexiglass tube 9 . Arranged in this way, it is convenient to adorn ice cubes or antifreeze in the plexiglass cylinder 9 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com