Chain for automobile engine

A technology for automobile engines and sleeves, which is applied in the direction of engine components, machines/engines, transmission chains, etc. It can solve the problems of undetermined wear mechanism, inability to exert durability, and easy "sticking" to achieve good lubricity and wear resistance The effect of good wear resistance and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Based on the examples, an embodiment of the present invention will be described with reference to FIGS. 1 to 5 . In addition, as can be seen from the above description, since the present invention is an invention aimed at improving the characteristic deterioration caused by the sliding contact between the inner surface of the bush and the outer surface of the pin, no matter whether it is a roller chain or a bush chain, the effect All show essentially the same tendencies. Therefore, in the description of the following embodiments, only the roller chain will be described.

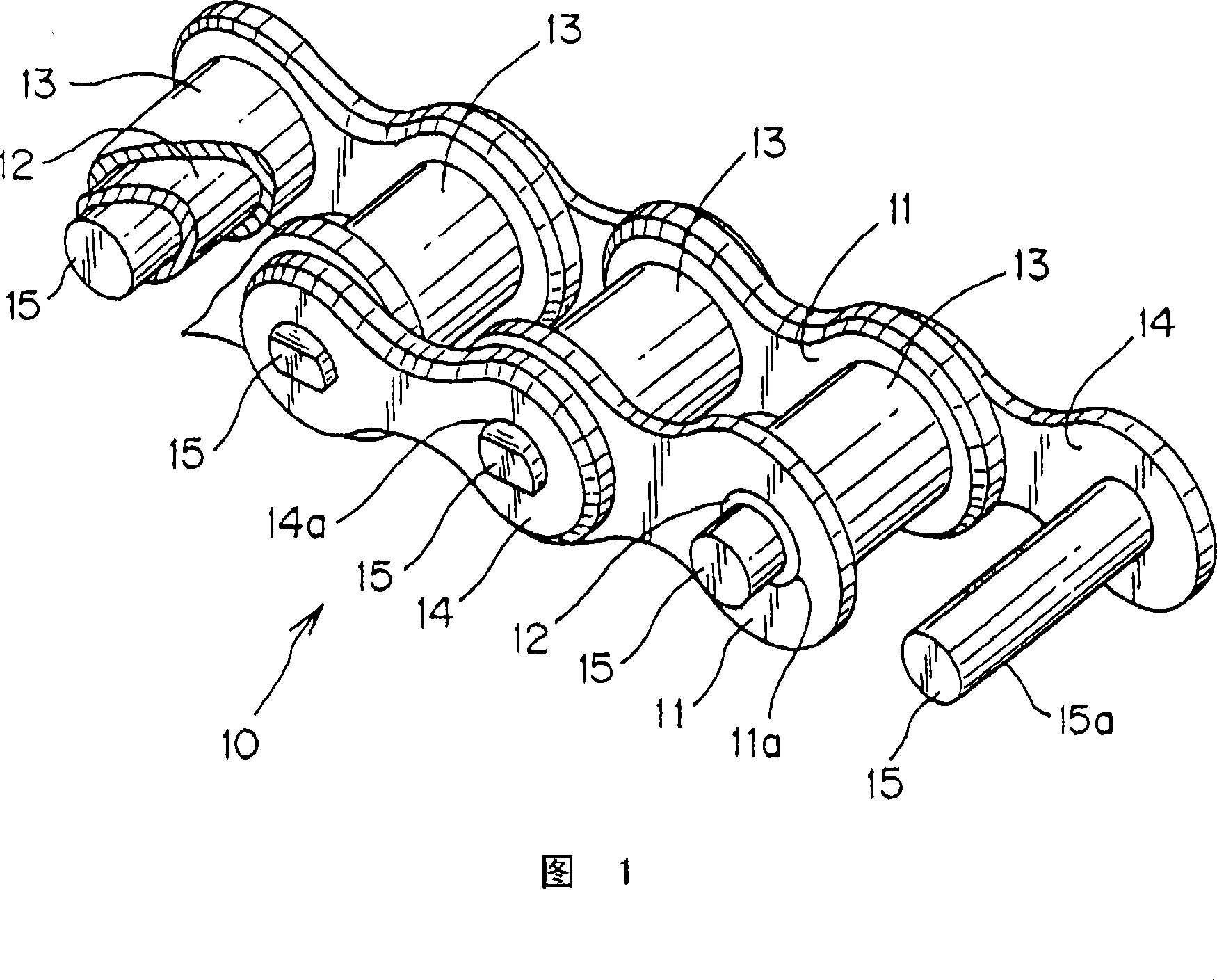

[0040] FIG. 1 is a perspective view showing a part of a roller chain as an embodiment of the present invention. In this FIG. 1 , it is shown in a partially cutaway state to clarify the internal structure of the roller chain.

[0041] In the roller chain 10, the two ends of the sleeve 12 are respectively pressed into the sleeve holes 11a of the pair of inner plates 11, and the two ends of the pin 15 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com