Automatic inspection equipment for power grid operation

A technology for automatic inspection and power grid operation. It is applied in the direction of using optical methods to test, measure electricity, and measure electrical variables. It can solve the problems of trouble finding hot spots, numerous equipment, and long time consumption, so as to avoid manual judgment errors, The effect of reducing carrying monitoring equipment and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

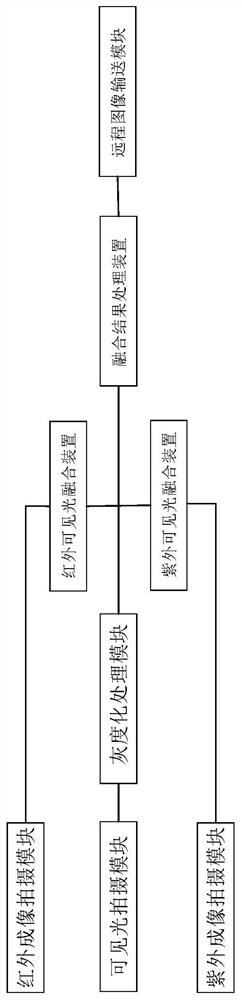

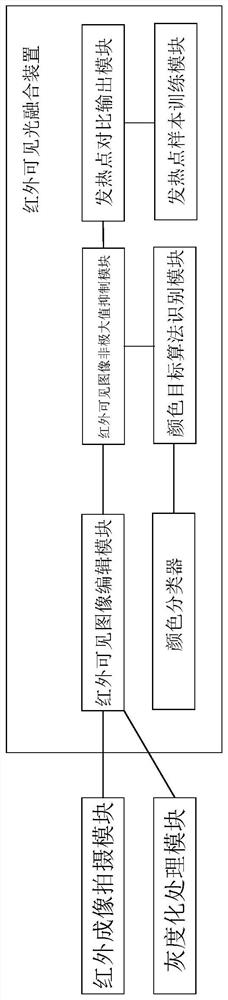

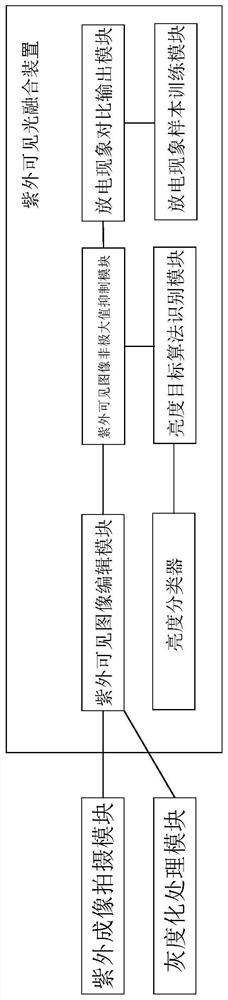

[0035] The following is attached Figure 1-7 The application is described in further detail.

[0036] The embodiment of this application discloses an automatic inspection equipment for power grid operation, refer to Figure 1-3 , including a visible light shooting module for generating visible light images, an infrared imaging shooting module for generating infrared images, an ultraviolet imaging shooting module for generating ultraviolet images, and a gray scale for grayscale processing of generated visible light images processing module, infrared-visible light fusion device, ultraviolet-visible light fusion device and fusion result processing device, the visible light shooting module is connected with the gray scale processing module; Hot spot training sample module, infrared visible light image editing module for cropping and superimposing visible light images and infrared images, color classifier for setting color targets corresponding to hot spot temperatures, color targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com