Real-time monitoring system and method for deep hole grouting water stop construction

A real-time monitoring and grouting technology, which is applied in earthwork drilling, electrical program control, program control in sequence/logic controller, etc. The key technical parameters of grouting speed and grouting time cannot be effectively monitored and controlled, so as to ensure the effect of grouting and water-stopping, strengthen the management of construction process, and predict the effect of grouting and water-stopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] In order to better understand the present invention, the content of the present invention will be further elaborated below in conjunction with examples. The embodiments described below with reference to the accompanying drawings are exemplary and intended to explain the present invention, but should not be construed as a limitation of the present invention.

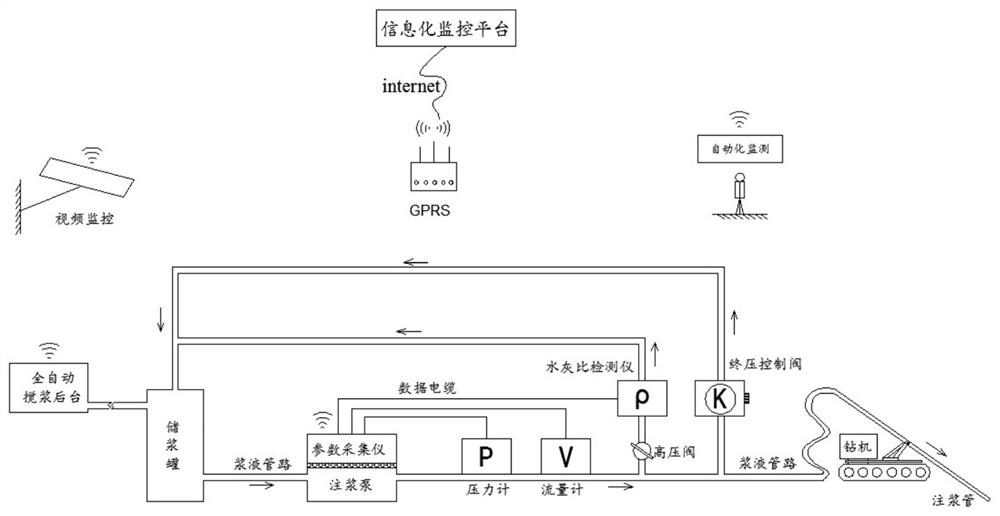

[0039] Such as figure 1 As shown, a real-time monitoring system for deep hole grouting and water sealing construction includes a video monitoring unit, an automatic monitoring unit, a fully automatic slurry mixing background, a parameter acquisition unit, a final pressure control valve and an information monitoring platform;

[0040] The video monitoring unit is arranged near the grouting background, grouting pump, and grouting drilling rig, and is used to record and monitor the grouting, pumping, hole forming, and pressure grouting processes of the grouting and water-stopping ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap