Three-dimensional laser scanning karst water inrush disaster magnitude evaluation test method and device

A three-dimensional laser and test method technology, applied in the field of tunnel engineering, can solve the problems of large evaluation deviation, slowing down the tunnel project start time, and long time consumption of disaster evaluation, saving time, improving evaluation accuracy, and realizing real-time online speed. The effect of information exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

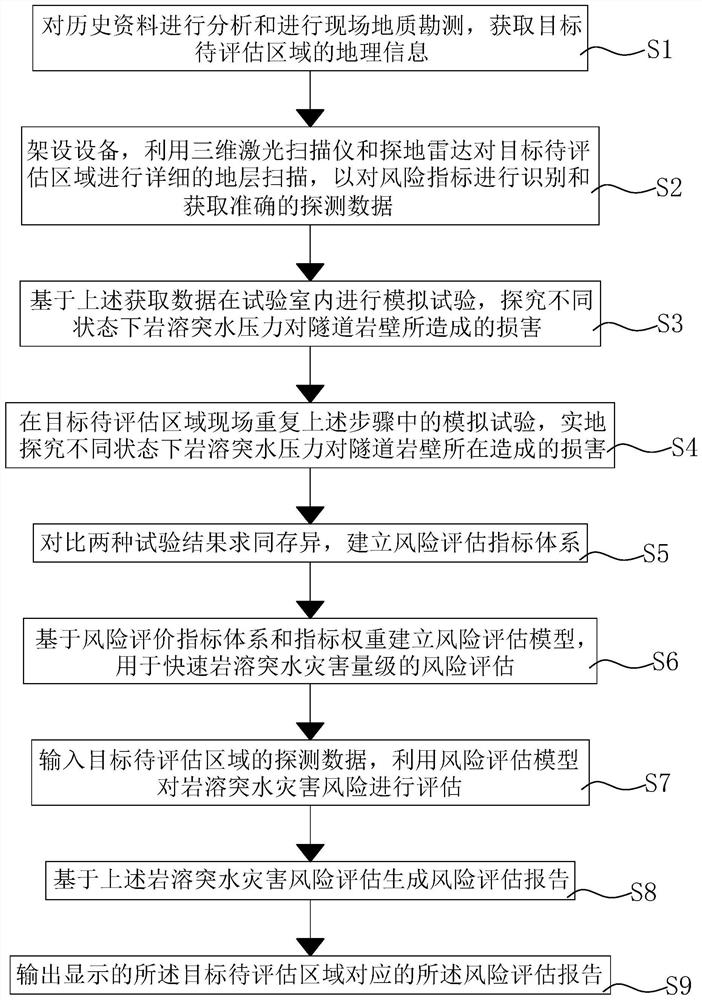

[0056] see figure 1 , a three-dimensional laser scanning karst water inrush disaster magnitude evaluation test method, comprising the following steps:

[0057] S1: Preparatory work, analyze historical data and conduct on-site geological survey, and obtain geographic information of the target area to be evaluated;

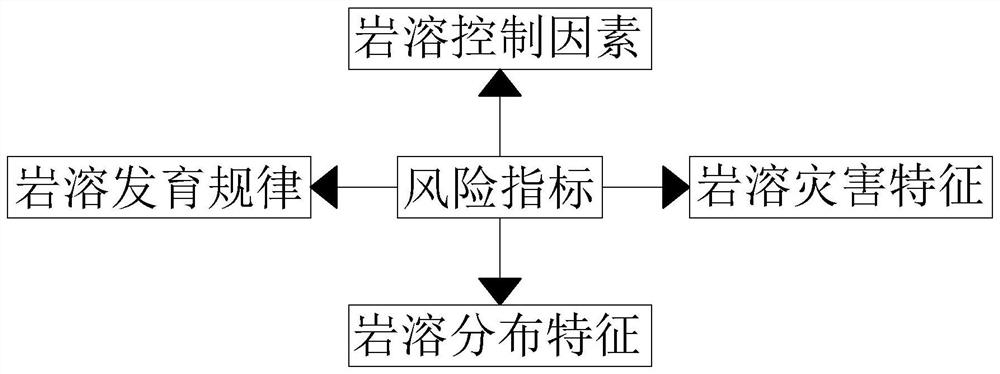

[0058] S2: Set up equipment, use the 3D laser scanner 14 and ground-penetrating radar to conduct detailed stratum scanning of the target area to be evaluated, so as to identify risk indicators and obtain accurate detection data;

[0059] S3: Carry out simulation tests in the laboratory based on the data obtained above to explore the damage caused by karst water inrush pressure on the tunnel rock wall under different conditions, and record the test data;

[0060] S4: Repeat the simulation test in the above steps in the target area to be evaluated, explore the damage caused by the karst water inrush pressure on the tunnel rock wall under different conditions, and rec...

Embodiment 2

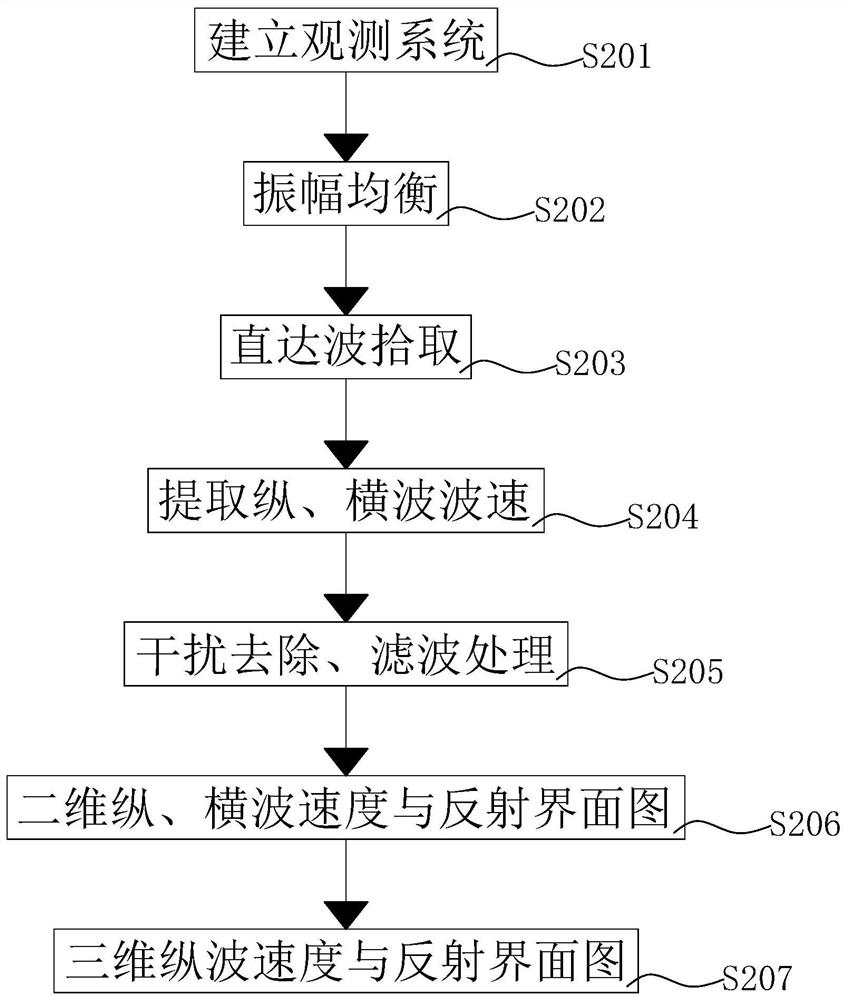

[0067] see Figure 2-4 , a three-dimensional laser scanning karst water inrush disaster magnitude evaluation test method, step S2 also includes the following steps:

[0068] S201: Establish an observation system in the program system carried by the evaluation device for geological survey of the target area to be evaluated;

[0069] S202: Debug the equipment and set system parameters, so that the amplitude of the detection laser waves emitted by the three-dimensional laser scanner 14 is kept balanced;

[0070] S203: Pick up the direct wave reflected and rebounded by the detection laser wave, and receive geological survey data.

[0071] S204: Extracting the wave velocity of the longitudinal wave and the shear wave of the rebound direct wave;

[0072] S205: Perform filtering processing on the longitudinal wave and the shear wave through a filter, and smooth the noise data to remove interference.

[0073] S206: Using two-dimensional longitudinal wave and shear wave velocity dat...

Embodiment 3

[0077] see Figure 5-6 , the present invention also provides a three-dimensional laser scanning karst water inrush disaster magnitude evaluation device, including a judging device 1, and the judging device 1 includes a CPU processor 11, a display 12, a peripheral interface 13, a three-dimensional laser scanner 14 and a wireless transceiver module 15. The CPU processor 11 has a built-in integrated memory, and the CPU processor 11 is electrically connected to the display 12 in one direction. The outside of the CPU processor 11 is provided with a peripheral interface 13, and the CPU processor 11 passes through the peripheral interface 13 In coordination with the electrical connection between the data connection line and the three-dimensional laser scanner 14, the wireless transceiver module 15 is arranged on the outer wall of the CPU processor 11, and is electrically connected with the CPU processor 11, and the CPU processor 11 communicates with the CPU processor 11 through the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com