Power transmission line wire icing thickness detection system and method

A technology of ice coating thickness and power transmission lines, which is applied in closed-circuit television systems, circuit devices, battery circuit devices, etc., can solve problems such as short circuits, uneven edges of wires, broken wires, etc., achieve broad application prospects, save manpower and material resources, and detect accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

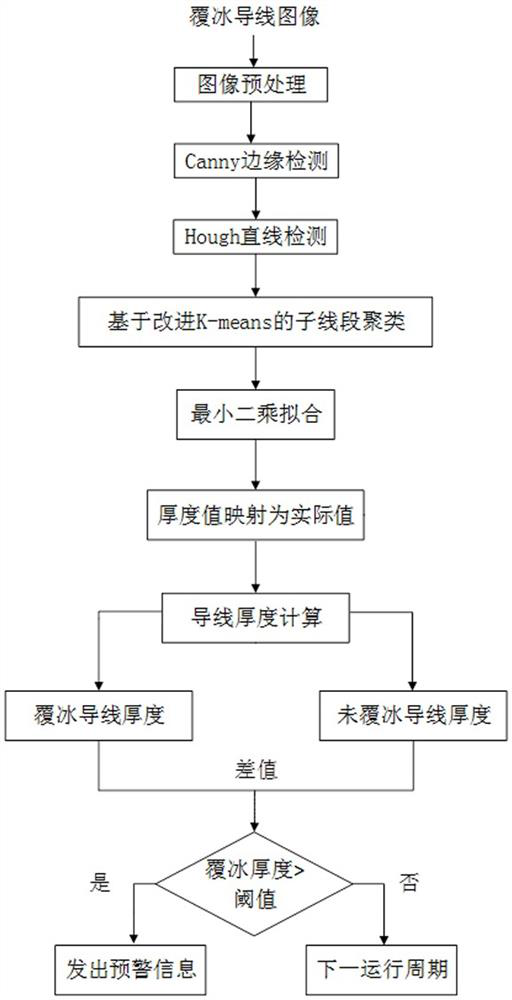

[0110] 1. Original wire image

[0111] There is a lot of noise in the background of the original wire image, such as Figure 9 shown.

[0112] 2. Image preprocessing

[0113] After image preprocessing, image noise is removed, and the contrast between the foreground and background areas of the image is improved at the same time, such as Figure 10 , which is convenient for subsequent identification.

[0114] 3. Canny edge detection

[0115] Use the Canny edge detection algorithm to extract the edges in the image, such as Figure 11 As shown, it can be seen that there are a large number of interfering line segments in the image, and the edges of the wires can also be completely detected.

[0116] 4. Hough line detection

[0117] On the basis of Canny detection, the straight line segment in the image is detected by the Hough line detection algorithm, and the detection effect is shown in the figure below. At this time, only the edge of the wire is in the image.

[0118] 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com