Direct insertion type copper-aluminum connector

An in-line connector technology, applied in the direction of connection, conductive connection, connection contact materials, etc., can solve the problems of electrical line disconnection or electrical fire, power energy consumption, etc., achieve stable quality, reduce contact resistance, length shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

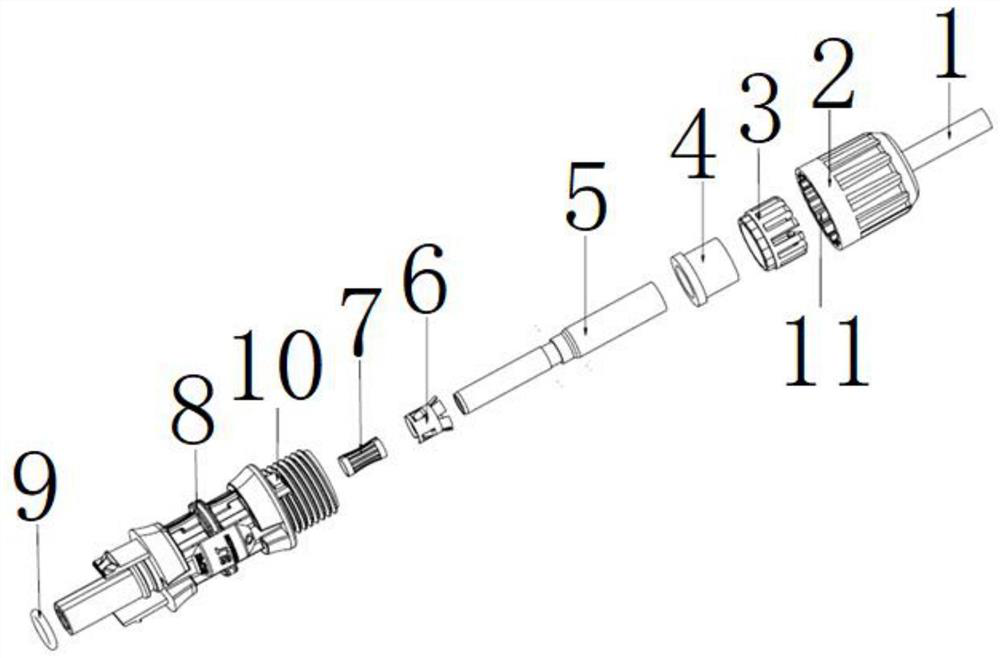

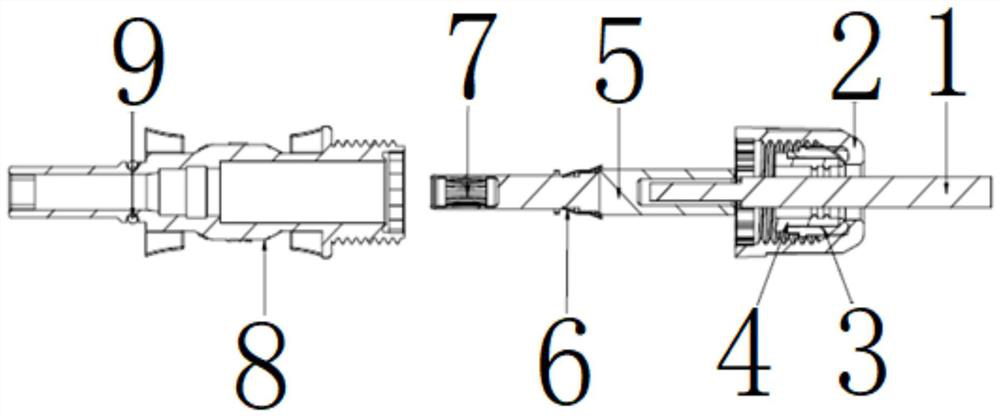

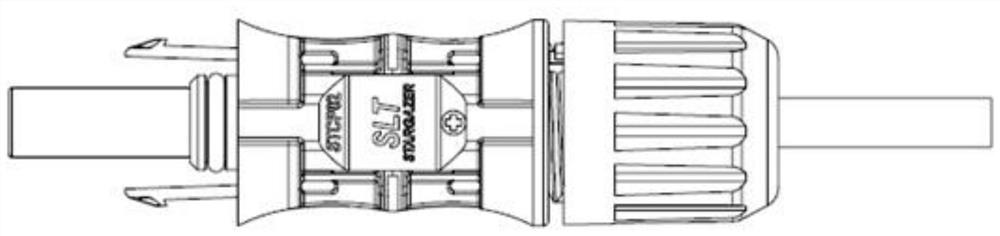

[0022] In-line copper-aluminum connectors include male and female ends, such as Figure 1-3 As shown, the male end includes a male-end plastic shell 8, and a male-end connector 5 is installed in the male-end plastic housing 8, and the male-end connector 5 is composed of a male-end copper tube and a male-end aluminum tube. The diameter of the terminal copper tube is smaller than the diameter of the male-end aluminum tube, and the male-end copper tube and the male-end aluminum tube are connected by friction welding, and the male-end aluminum tube is connected to the aluminum cable 1 (crimping connection); the male-end One end of the plastic housing 8 has an insertion tube, and the male-end copper tube of the male-end connector is inserted into the insertion tube from the male-end plastic housing 8. At the head of the insertion tube, a tubular inner shrapnel 7 ( The two ends of the tubular inner shrapnel are fixed on the inner side of the insertion tube, the middle part of the tu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap