Gas anesthesia device

A gas, anesthesia mask technology, applied in the field of medical devices, can solve the problems of inconvenience, easy overflow, pollution, etc., and achieve the effects of convenient adjustment, pollution reduction, and convenient concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

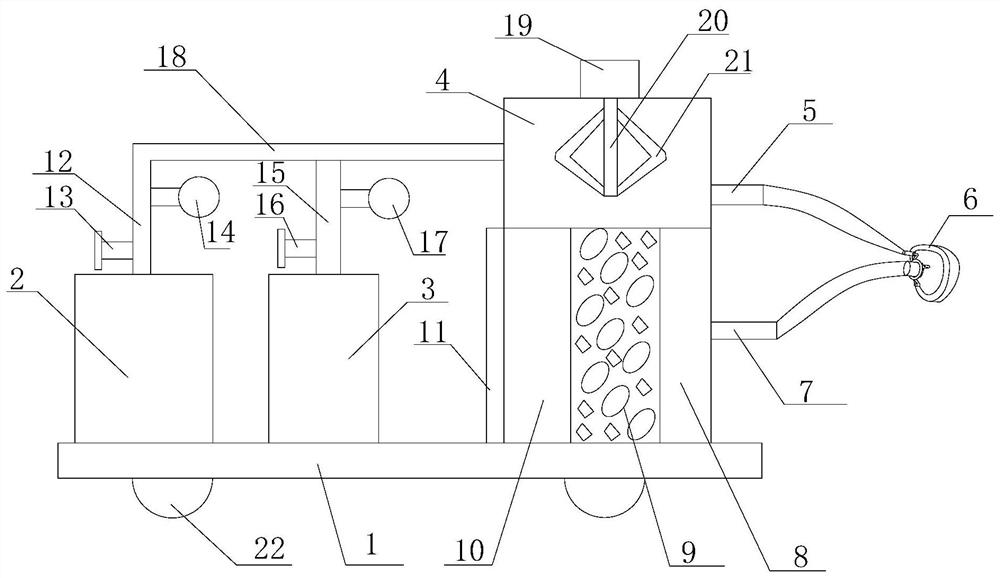

[0023] Such as Figure 1 to Figure 3 As shown, the gas anesthesia device of the present invention includes a support plate 1 on which an anesthetic gas tank 2, an oxygen tank 3, a mixing mechanism, a waste gas recovery device and an anesthesia cover 6 are arranged; 2 is provided with a first air pipe 12, and is equipped with a first valve 13 and a first flow meter 14; the oxygen tank 3 is provided with a second air pipe 15, and is equipped with a second valve 16 and a second flow meter 17; also includes a third air pipe 18, the first air pipe 12 and the second air pipe 15 are both communicated with the third air pipe 18, and the third air pipe 18 is communicated with the mixing mechanism; the anesthesia cover 6 They are respectively communicated with the mixing mechanism and the waste gas recovery device. The gas anesthesia device of the present invention, through the cooperation of the support plate 1, the anesthetic gas tank 2, the oxygen tank 3, the mixing mechanism, the w...

Embodiment 2

[0025] On the basis of the above embodiments, in order to further better implement the present invention, the mixing mechanism includes a mixing tank 4 arranged on the support plate 1, one side of the mixing tank 4 communicates with the third air pipe 18, and the other Side is provided with output pipe 5, and this output pipe 5 communicates with described anesthesia cover 6 through the first flexible pipe; The top of described mixing tank 4 is provided with stirring motor 19, and the rotating shaft 20 of this stirring motor 19 stretches into mixing The tank 4 is equipped with corresponding bearings and sealing rings, and the rotating shaft 20 is provided with a disturbance vane 21 . After this design, the stirring motor 19 starts to drive the rotating shaft 20 to rotate, thereby driving the disturbance blade 21 to disturb. When the anesthetic gas and oxygen enter the mixing tank 4, they are evenly mixed under the disturbance of the disturbance blade 21, and the mixing is quite ...

Embodiment 3

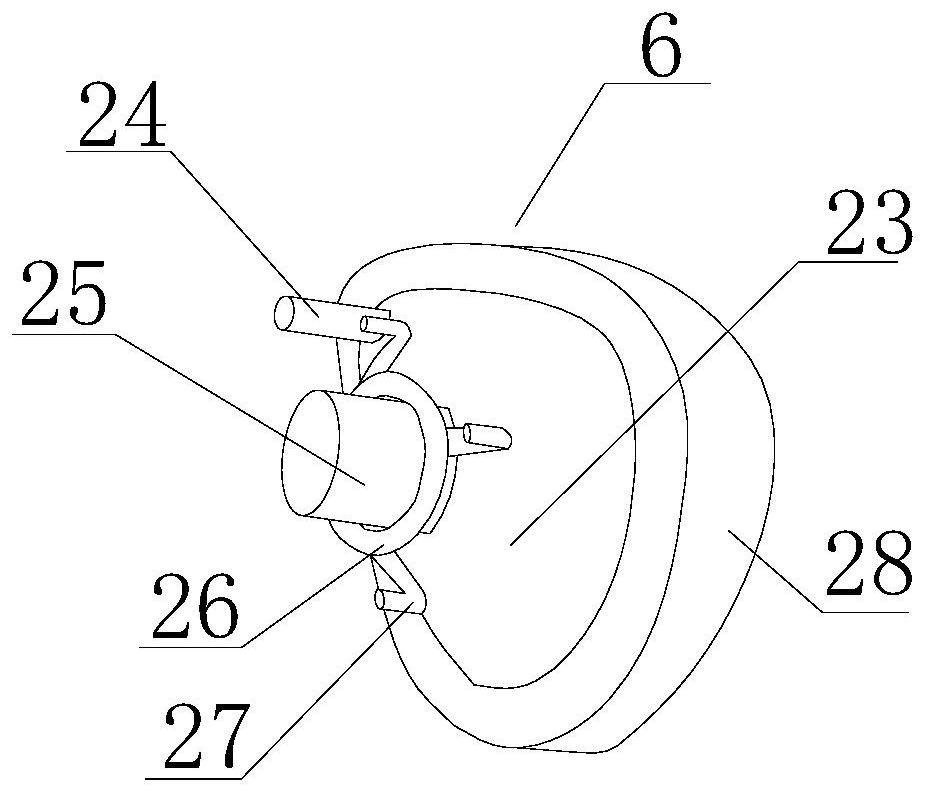

[0028] On the basis of the above-described embodiments, in order to further better implement the present invention, the anesthesia cover 6 includes a cover body 23, and a silicone pad 28 that improves the sealing performance is provided at the part where the cover body 23 cooperates with the human face; The cover body 23 is provided with an anesthetic gas inlet 24 and a waste gas discharge port 25, the anesthetic gas inlet 24 is connected to the first hose, and the waste gas discharge port 25 is connected to a waste recycling device. When in use, cover the mouth and nose of the human face with the mask body 23, make the silicone pad 28 fit the face, the anesthetic gas mixed with the mixing tank 4 enters from the anesthetic gas inlet 24, and the exhaust gas produced by the patient's inhalation of the anesthetic gas is exhaled When the exhaust gas is transported to the exhaust gas recovery device through the exhaust gas discharge port 25, the pollution is greatly reduced.

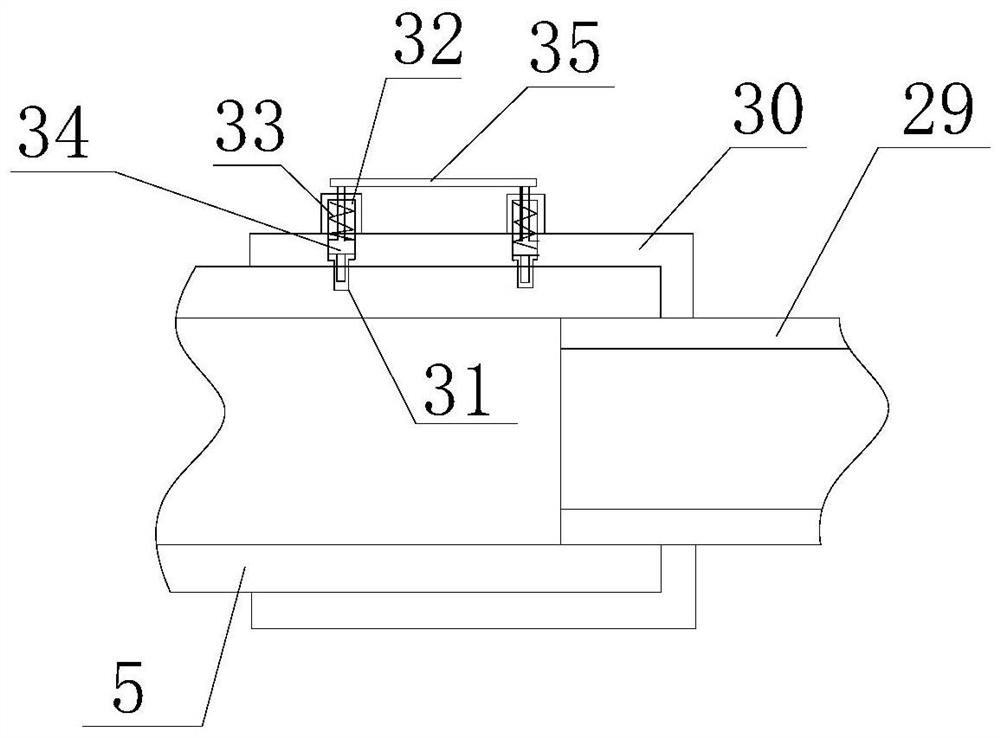

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com