A kind of preparation method of crsibcn nanocomposite thin film

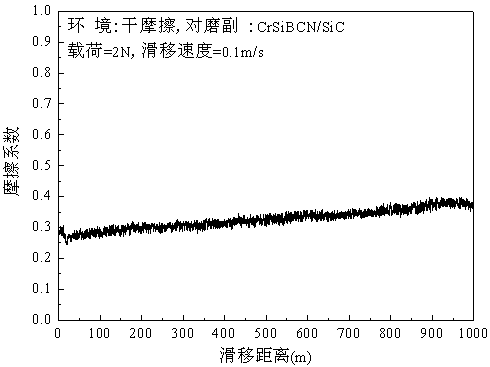

A nano-composite and thin-film technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems that CrN thin film is not suitable for application, and achieve the effect of improving hardness and reducing dry friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

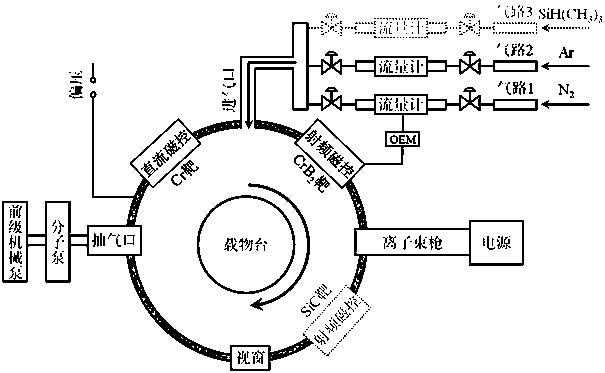

[0021] (1) Substrate cleaning: 316L stainless steel (Φ30×6 mm) whose roughness is polished to 50 nm 2 ) Carry out ultrasonic cleaning in acetone, alcohol and deionized water for 10 minutes each, blow dry with a hair dryer and clamp on the stage of the physical vapor deposition system, 17 cm away from the target; when the background vacuum of the physical vapor deposition system Degree reaches 3.0×10 -6 At Torr, add 50sccm of Ar gas, set the bias voltage of the stainless steel substrate to -450V, and use the Ar generated by the ion beam source + Ions accelerated the bombardment of the 316L stainless steel surface for 30 minutes to remove contaminants on the substrate surface and activate the deposition surface;

[0022] (2) Preparation of transition layer: Ar + After the substrate is cleaned by ion bombardment, maintain the Ar gas flow rate at 50 sccm, adjust the bias voltage of the stainless steel substrate to -80V, and load the metal Cr target with a power of 1200 W through a dire...

Embodiment 2

[0025] (1) Substrate cleaning: 316L stainless steel (Φ30×6 mm) whose roughness is polished to 50 nm 2 ) Carry out ultrasonic cleaning in acetone, alcohol and deionized water for 10 minutes each, blow dry with a hair dryer and clamp on the stage of the physical vapor deposition system, 17 cm away from the target; when the background vacuum of the physical vapor deposition system Degree reaches 3.0×10 -6 At Torr, add 50sccm of Ar gas, set the stainless steel substrate bias voltage -450V, and use the Ar generated by the ion beam source + Ions accelerated the bombardment of the 316L stainless steel surface for 30 minutes to remove contaminants on the substrate surface and activate the deposition surface;

[0026] (2) Preparation of transition layer: Ar + After the substrate is cleaned by ion bombardment, maintain the Ar gas flow rate at 50 sccm, adjust the bias voltage of the stainless steel substrate to -80V, and load the metal Cr target with a power of 1200 W through a direct current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com