A kind of ablation-resistant carbon/carbon-zirconium carbide-copper composite material and preparation method thereof

A composite material, zirconium carbide technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of easy agglomeration of additives, difficult preparation, crusting, etc., to improve ablation resistance, The effect of improving overall performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

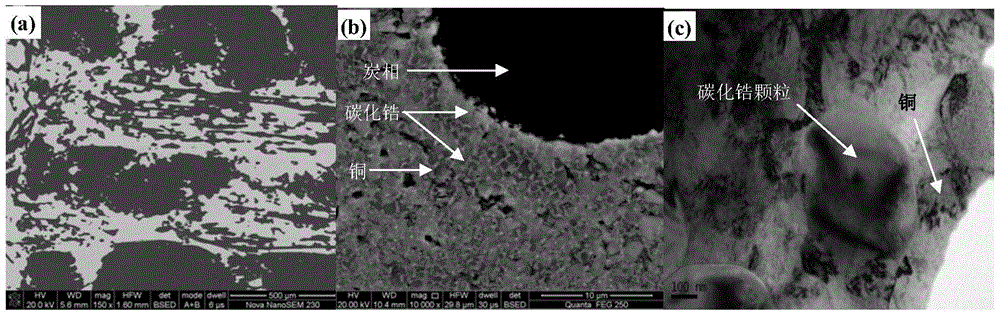

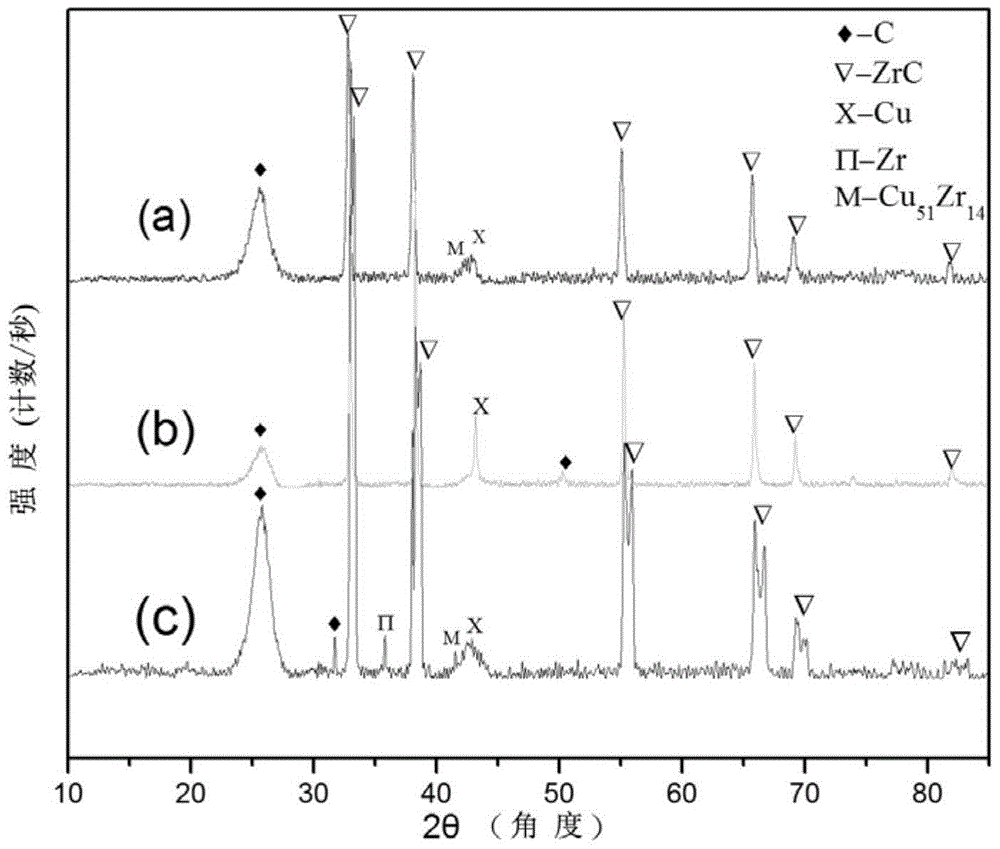

[0048] (1) Use polyacrylonitrile-based carbon fiber needle-punched integral felt as a prefabricated body (density 0.4g / cm 3 ), in high purity N 2 Carrier gas, C 3 h 6 A carbon / carbon composite green body with a porosity of about 50% (density of 1.0 g / cm 3 );

[0049] (2) prepare zirconium-copper mixed powder, wherein the mass percentage of zirconium powder is 50%;

[0050] (3) Embedding the carbon / carbon composite body of step (1) in the mixed powder of step (2), under the vacuum condition of 1200 ℃ (vacuum degree is less than or equal to 10 -2 atm) under infiltration treatment 4h, after the reaction, carbon / carbon-zirconium carbide-copper composite material is obtained; its composition mass ratio is, carbon / carbon composite green body: zirconium carbide: copper and / or copper-zirconium alloy=32.28:23.1: 44.62.

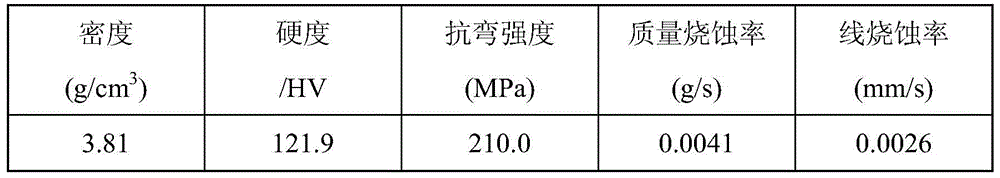

[0051] (4) The carbon / carbon-zirconium carbide-copper composite material is processed into a Φ30*10mm cylinder, and the oxygen-acetylene ablation experiment is c...

Embodiment 2

[0055] (1) Use polyacrylonitrile-based carbon fiber needle-punched integral felt as a prefabricated body (density 0.4g / cm 3 ), in high purity N 2 Carrier gas, C 3 h 6 A carbon / carbon composite green body with a porosity of about 40% (density of 1.2 g / cm 3 );

[0056] (2) prepare zirconium-copper mixed powder, wherein the mass percentage of zirconium powder is 60%;

[0057] (3) Embedding the carbon / carbon composite green body of step (1) in the mixed powder of step (2), under the vacuum condition of 1350 ℃ (vacuum degree is less than or equal to 10 -2 atm) under infiltration treatment for 3h, after the reaction, carbon / carbon-zirconium carbide-copper composite material is obtained; its composition mass ratio is, carbon / carbon composite green body: zirconium carbide: copper and / or copper-zirconium alloy=28.38:43.2: 28.42.

[0058] (4) The carbon / carbon-zirconium carbide-copper composite material is processed into a Φ30*10mm cylinder, and the oxygen-acetylene ablation exper...

Embodiment 3

[0062] (1) Use polyacrylonitrile-based carbon fiber needle-punched integral felt as a prefabricated body (density 0.5g / cm 3 ), in high purity N 2 Diluent gas, C 3 h 6 A carbon / carbon composite green body with a porosity of about 30% (density of 1.4 g / cm 3 );

[0063] (2) prepare zirconium-copper mixed powder, wherein the mass percentage of zirconium powder is 70%;

[0064] (3) Embedding the carbon / carbon composite body of step (1) in the mixed powder of step (2), under the vacuum condition of 1500 ℃ (vacuum degree is less than or equal to 10 -2 atm) under infiltration treatment 2h, after the reaction, carbon / carbon-zirconium carbide-copper composite material is obtained; its composition mass ratio is, carbon / carbon composite green body: zirconium carbide: copper and / or copper-zirconium alloy=44.74:40.5: 14.76.

[0065] (4) The carbon / carbon-zirconium carbide-copper composite material is processed into a Φ30*10mm cylinder, and the oxygen-acetylene ablation experiment is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com