A cement column pouring equipment for fruit racks

A technology for cement columns and fruit racks, applied in ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems of low labor intensity, high labor intensity, and low cement column pouring efficiency, so as to improve efficiency and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

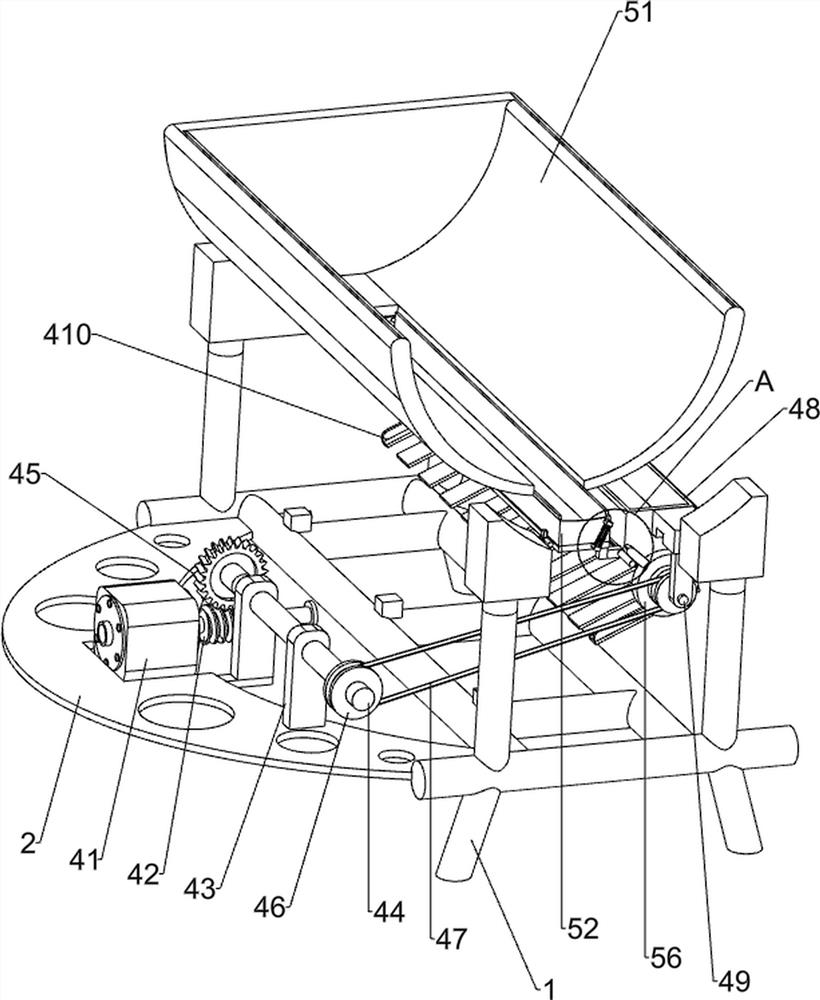

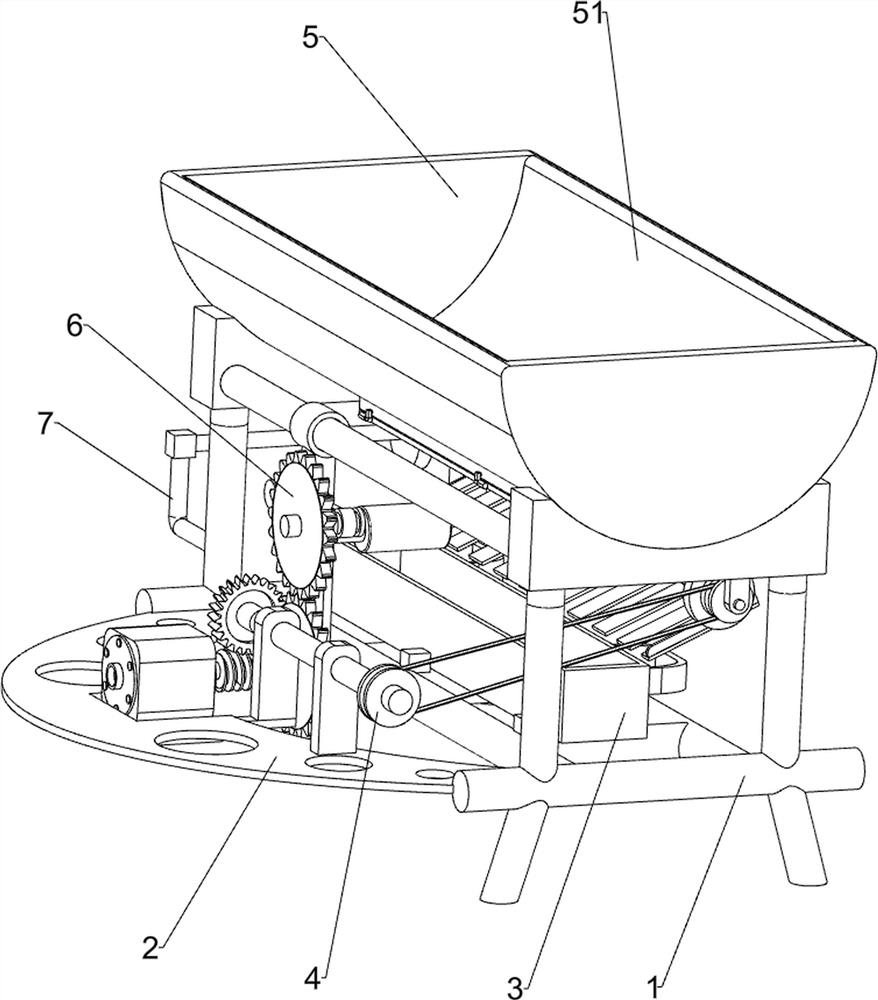

[0023] A kind of cement column pouring equipment for fruit racks, such as Figure 1-3 As shown, it includes a platform 1, a mounting plate 2, a mold box 3, a blanking mechanism 4 and a material leakage mechanism 5, the left side of the platform 1 is connected with a mounting plate 2, and the middle part of the platform 1 is placed with a mold box 3, A blanking mechanism 4 is connected between the platform 1 and the mounting plate 2 , and a material leakage mechanism 5 is connected between the platform 1 and the blanking mechanism 4 .

[0024] Blanking mechanism 4 comprises reduction motor 41, worm screw 42, bearing 43, rotating rod 44, worm wheel 45, belt pulley 46, flat belt 47, placement box 48, feeding rod 49 and baffle plate 410, the middle of mounting plate 2 tops A reduction motor 41 is installed at the position, and the middle part of the output shaft of the reduction motor 41 is connected with a worm screw 42. The front side of the mounting plate 2 top is connected wit...

Embodiment 2

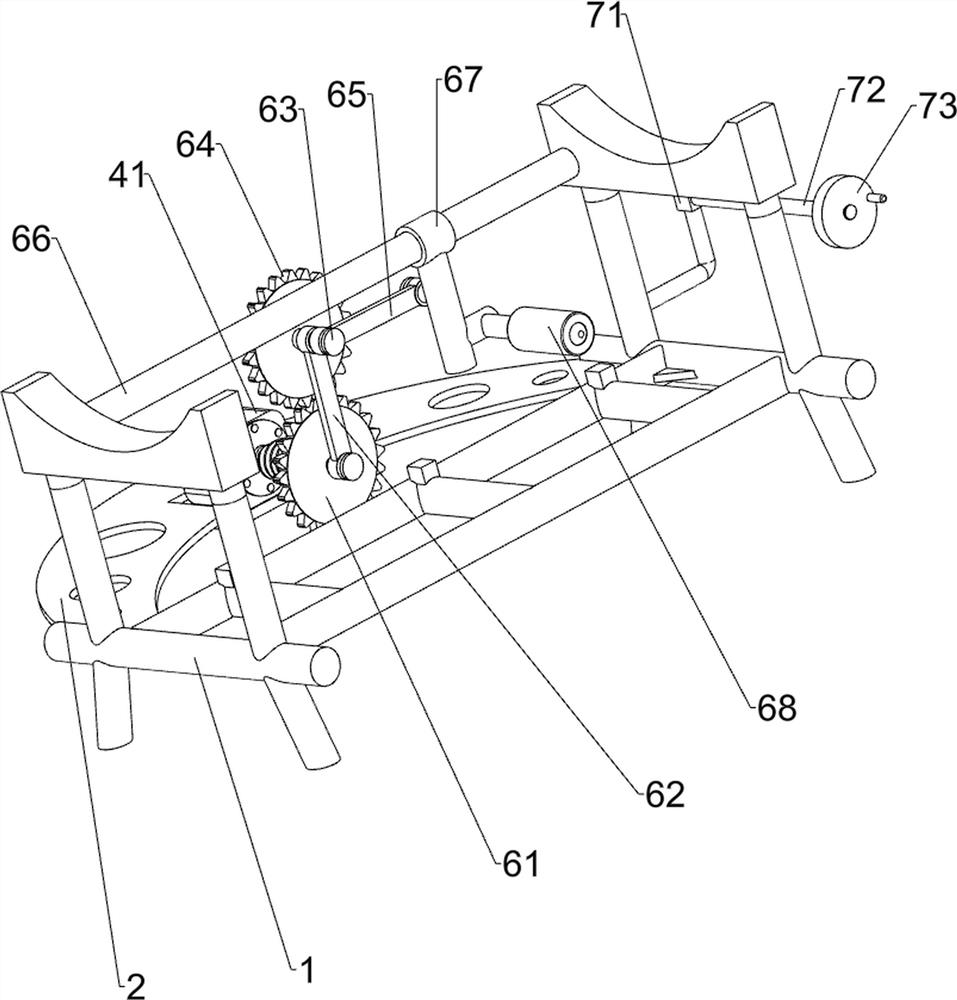

[0028] On the basis of Example 1, such as Figure 4 Shown, also include extruding mechanism 6, extruding mechanism 6 includes first gear 61, first connecting rod 62, rotating shaft 63, second gear 64, second connecting rod 65, slide bar 66, sliding sleeve 67 and The drum 68 is connected with the first gear 61 and the first connecting rod 62 at the tail end of the output shaft of the reduction motor 41, the first connecting rod 62 is connected with the right side of the first gear 61, and the top of the first connecting rod 62 is rotationally connected with Rotating shaft 63, the left side of rotating shaft 63 is connected with the second gear 64, and the second gear 64 and the first gear 61 mesh with each other, and the right side of rotating shaft 63 is connected with the second connecting rod 65 rotationally, and the rear end of the second connecting rod 65 Rotationally connected with sliding sleeve 67, the rear side of sliding sleeve 67 bottom is connected with cylinder 68,...

Embodiment 3

[0031] On the basis of Example 2, such as Figure 4 Shown, also include fixed mechanism 7, fixed mechanism 7 includes L-shaped fixed rod 71, round rod 72 and rotating disk 73, the left rear side of stand 1 is connected with L-shaped fixed rod 71, the top of L-shaped fixed rod 71 A round rod 72 is connected, and the right side of the round rod 72 is connected with a turntable 73 in a threaded manner.

[0032]When people need to pour the cement column, turn the turntable 73 and take it out, put the whole roll of film into the round rod 72, then turn the turntable 73 to reset, people only need to pull one end of the film to cover the film on the mold box 3 In this way, the film covering on the mold box 3 can be quickly realized, and the film is covered on the mold box 3 without the cooperation of two people, which further improves the efficiency of people pouring the cement column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com