Processing technology of filling type heat-conducting silicone rubber

A heat-conducting silicone rubber, processing technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of unbalanced thermal conductivity and low thermal expansion coefficient, inability to obtain silicone rubber products, and increased production costs of silicone rubber, etc. Achieve the effect of maintaining performance advantages, low product switching costs, and easy formulation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

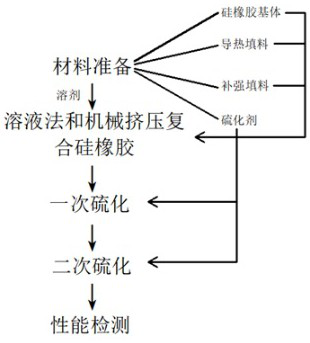

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] refer to figure 1 , a processing technology of filled heat-conducting silicone rubber, comprising the following steps:

[0024] S1: Material preparation: The raw materials for filling thermally conductive silicone rubber include silicone rubber matrix, thermally conductive filler and vulcanizing agent;

[0025] S2: Composite silicone rubber by solution method: first dissolve the silicone rubber matrix into an appropriate solvent, and then mix it evenly with the thermally conductive filler, and dissolve the silicone rubber matrix to form a liquid thermally conductive silica gel;

[0026] S3: Primary vulcanization: After the liquid heat-conducting silica gel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com