A construction method for freezing and strengthening shield tail brush replacement

A construction method, shield tail brush technology, applied in metal processing equipment, manufacturing tools, earthwork drilling and mining, etc., can solve problems such as poor freezing effect, achieve the effect of convenient operation, large heat transfer area, and little impact on stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

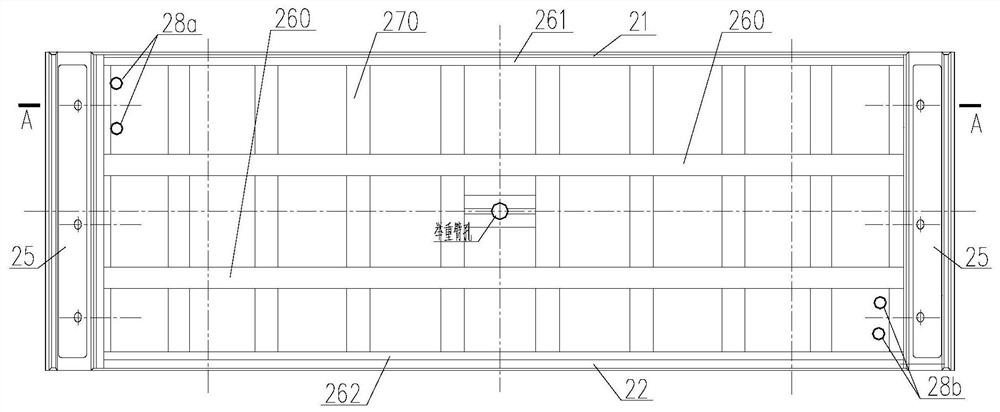

[0077] The present invention will be further described below in conjunction with accompanying drawing.

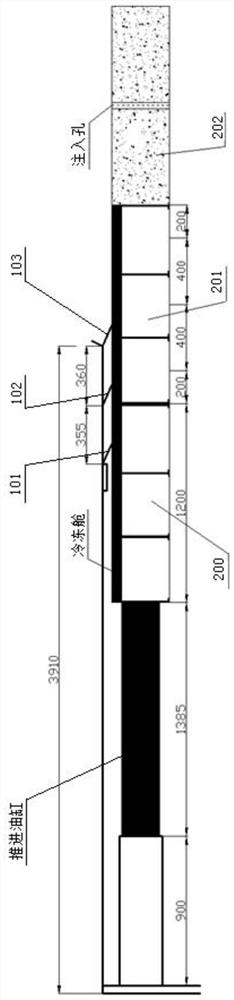

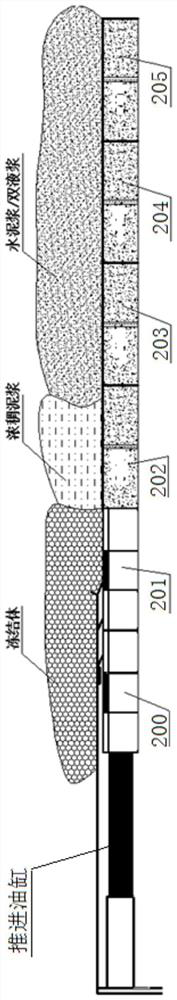

[0078] see Figure 1 to Figure 6 , the freezing reinforcement of the present invention to replace the construction method of the shield tail brush, the shield machine has three shield tail brushes, the first shield tail brush 101 and the second shield tail brush 102 and the second shield tail brush 102 and the third shield tail brush 103 form a grease cavity respectively.

[0079] The construction method of the present invention is used to replace the first shield tail brush, including the following processes: before the shield tail brush is replaced and shut down for construction, water stop ring construction, stratum freezing construction, shield tail brush replacement and recovery of excavation;

[0080] The construction process before the shield tail brush is replaced and shut down includes the following steps:

[0081]Step 1: Select the position of the last ring segm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com