Teeth synergistic three-dimensional wobble plate piston engine

A piston engine, three-dimensional technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of axial piston structure failure, machine failure, complex structure, etc., and achieve unfavorable load reduction, high power-to-weight ratio, windward small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

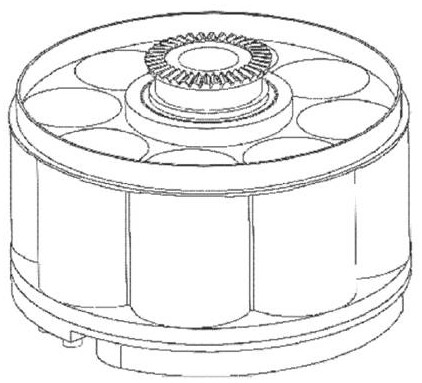

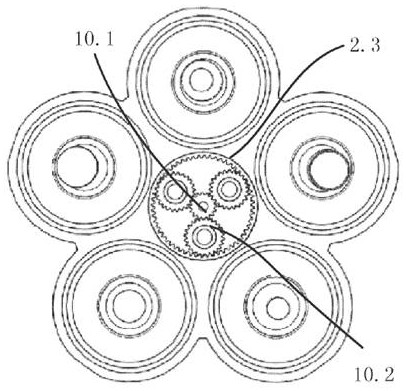

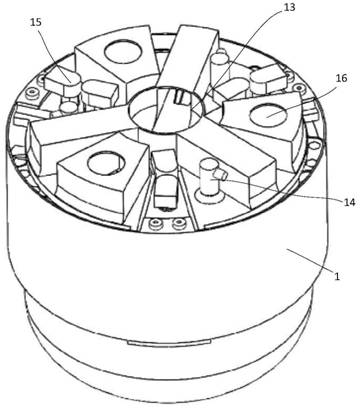

[0040] As shown in the figure, the teeth cooperative three-dimensional wobble plate piston engine of the present invention includes a base body 1, a main shaft 7, a cylinder body 2, a transmission assembly and a cooperative tooth assembly;

[0041] The cylinder block 2 has a central axis, and the cylinder block includes at least two cylinders arranged in a circular array parallel to the central axis, as shown in the figure, the axes of the cylinders are parallel to the central axis; a piston 9 is arranged in cooperation with the cylinders , a connecting rod 8 is arranged in cooperation with the piston 9, and the cylinder body 2 is fixedly arranged. The fixed arrangement here refers to the overall fixing of the cylinder body during use, which can be fixed on the basis of setting, and will not be repeated here; As shown in the figure, the cylinder body is fixed on a base body, and the setting method can be realized by using a common mechanical structure, so I won’t repeat it here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com