Automatic fuel calibration device and method for electric injection system

An automatic calibration and fuel technology, which is applied to fuel injection devices, measuring devices, charging systems, etc., can solve the problems of long time required and low efficiency, and achieve the effect of saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

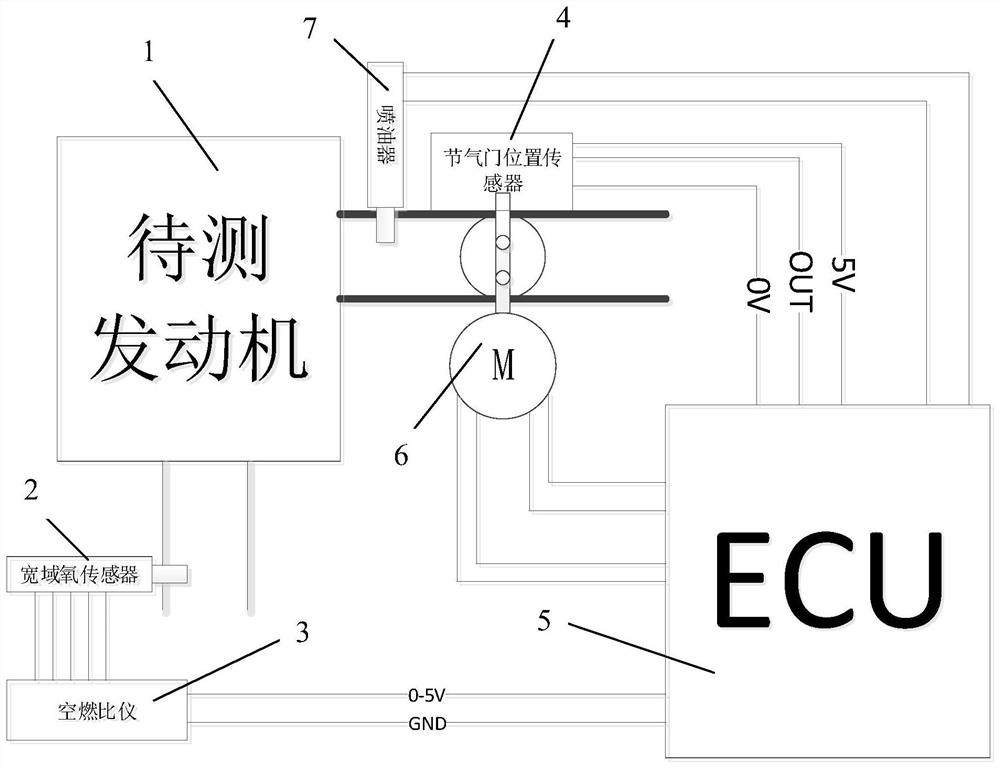

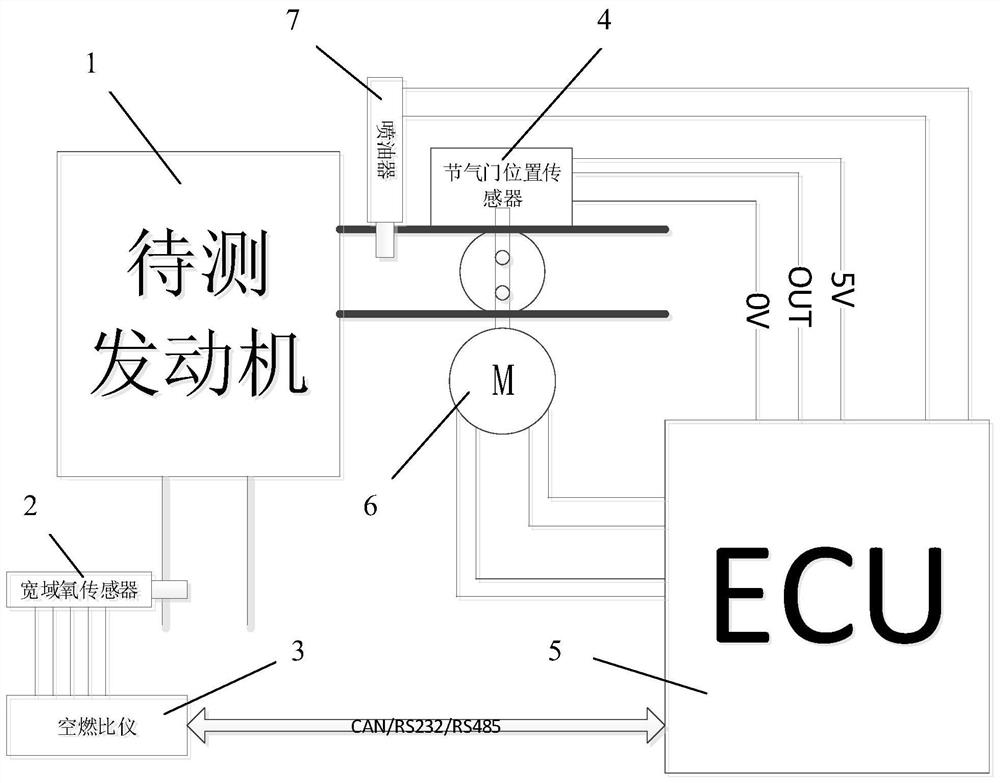

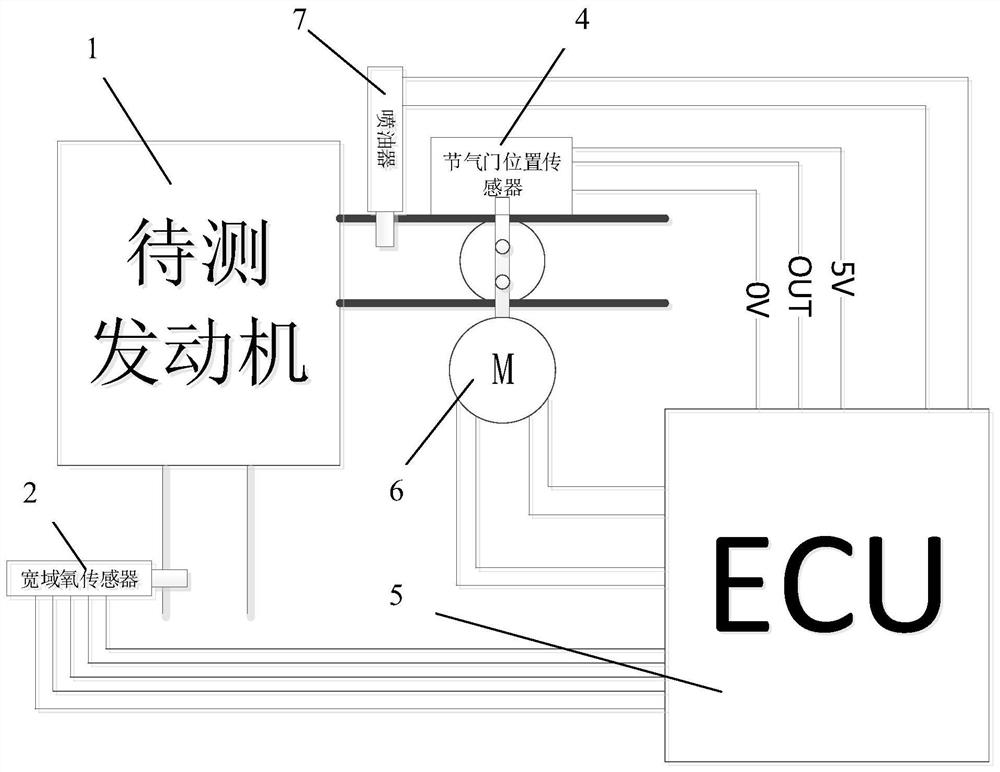

[0048] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0049] see figure 1 , figure 1It is a schematic diagram of the device structure of an embodiment of the present invention. Before the EFI system of the engine is put into mass production, various parameters of the engine need to be calibrated, including basic fuel injection pulse width, temperature correction, transient correction, plateau correction, etc. The electronic fuel injection system fuel automatic calibration device of the present invention is suitable for the basic fuel injection pulse width calibration of the engine electronic injection system, including: a dynamometer (not shown), the crankshaft output end of the engine to be tested 1 and the dynamometer The main function of the engine bench is to measure the power of the engine. There are two ways to measure the power of the AC dynamometer, one is constant spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com