Static scroll plate assembly, scroll compressor and refrigeration equipment

A scroll compressor and stationary scroll technology, applied in compressors, mechanical equipment, lighting and heating equipment, etc., can solve problems such as loud noise, backflow, and influence on the reliability of the scroll compressor 200'

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

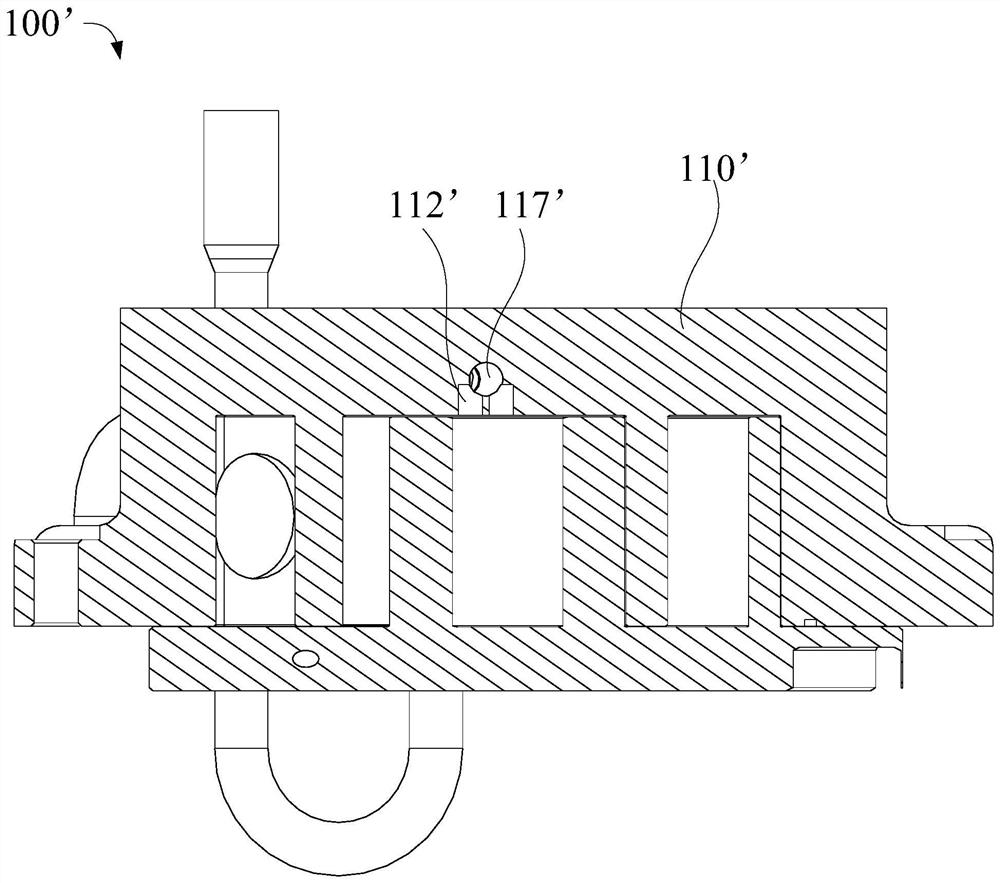

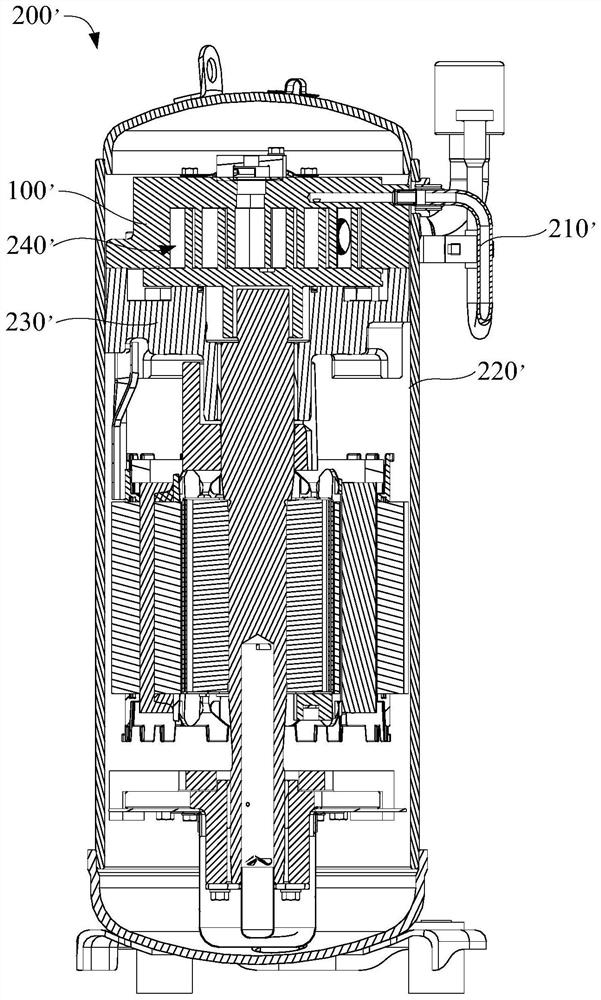

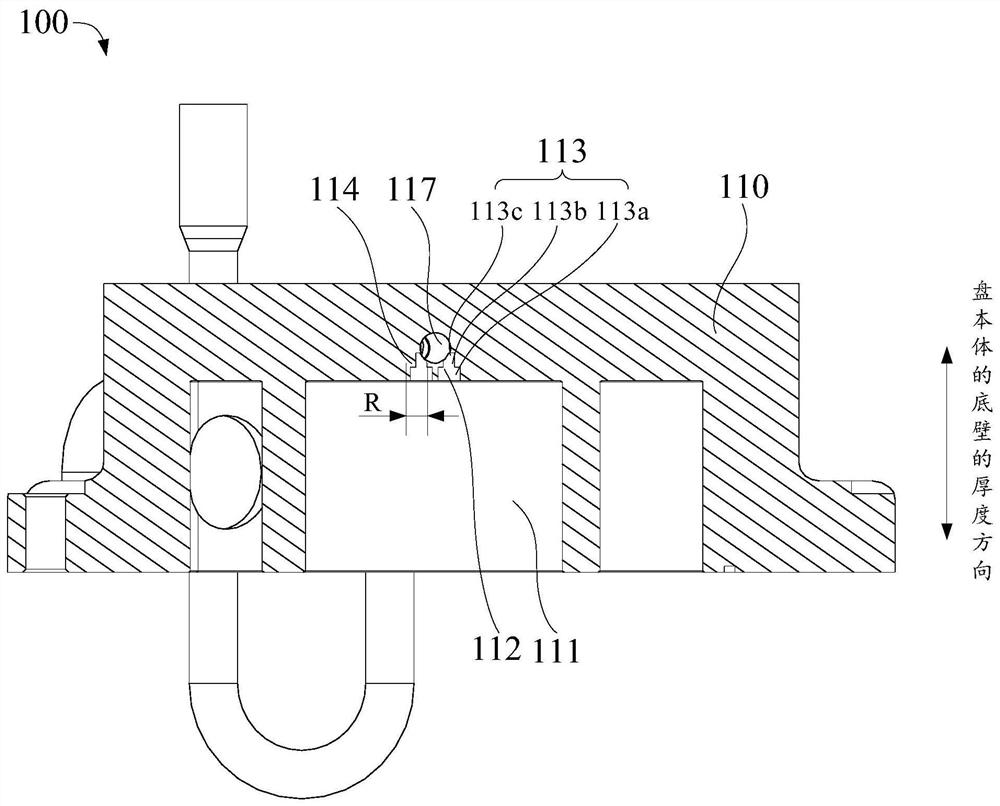

[0081] Such as image 3 , Figure 7 , Figure 8 and Figure 9 As shown, the embodiment of the first aspect of the present invention provides a fixed scroll assembly 100 , and the fixed scroll assembly 100 includes a disk body 110 , an enthalpy increasing channel 117 and an enthalpy injecting channel 112 . Wherein, the disc body 110 includes a bottom wall surface and a worm gear arranged on the bottom wall surface, and the bottom wall surface and the worm gear surround to form a compression passage 111, the compression passage 111 of the fixed scroll assembly 100 and the compression passage 111 of the movable scroll 230 Together form the compression chamber 240 of the scroll compressor 200 . The enthalpy-increasing channel 117 and the enthalpy-injecting channel 112 are arranged on the disc body 110, the enthalpy-increasing channel 117 is used to communicate with the enthalpy-increasing pipeline 210 of the scroll compressor 200, and the enthalpy-injecting channel 112 communic...

Embodiment 2

[0087] On the basis of the first embodiment above, the side wall surface 113 of the enthalpy injection channel 112 is further formed into a flow blocking part, that is, the gas in the compression channel 111 is prevented from flowing back into the enthalpy increasing channel 117 through the side wall surface 113 of the enthalpy injection channel 112 . On the one hand, there is no need for additional flow blocking parts, only the side wall surface 113 of the enthalpy injection channel 112 is designed to be suitable for hindering the gas backflow, reducing parts and saving costs; Compared with the solutions such as setting a choke plug inside, it can prevent a large amount of gas in the compression channel 111 from flowing back into the enthalpy increasing channel 117, and at the same time, it will not excessively hinder the passage of the refrigerant gas through the enthalpy increasing pipeline 210 and increasing enthalpy of the scroll compressor 200. The enthalpy passage 117 a...

Embodiment 3

[0090] On the basis of the second embodiment above, the enthalpy injection channel 112 is further made to penetrate the bottom wall of the disk body 110 at the first position, that is, the enthalpy injection channel 112 penetrates the side of the disk body 110 facing the compression channel 111 at the first position The wall surface communicates with the compression channel 111. The first position is where the through opening of the enthalpy injection channel 112 runs through the bottom wall of the disk body 110 , so other positions of the enthalpy injection channel 112 are farther away from the compression channel 111 than the first position. Make the cross-sectional area of the enthalpy injection channel 112 at the first position larger than the cross-sectional area of the enthalpy injection channel 112 at the second position. Compared with the cross-sectional area of the enthalpy injection channel 112' in the related art, the gas in the compression chamber 240' will f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com