Quartz tuning fork gyroscope gauge outfit screening and testing device

A quartz tuning fork and testing device technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as performance evaluation, achieve the effect of quick installation and improve the efficiency of screening and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

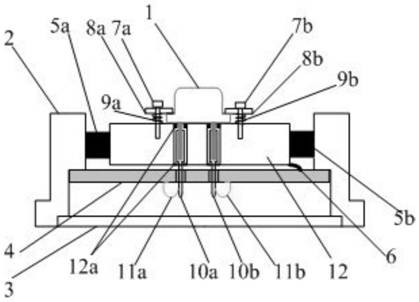

[0019] A kind of quartz tuning fork gyroscope head screening test device of the present invention is introduced below in conjunction with accompanying drawing and embodiment:

[0020] like figure 1 As shown, a quartz tuning fork gyro head screening test device consists of a tooling shell structure 2, a cover plate 3, a head mounting bracket 12, a measurement and control circuit 4, vibration damping components 5a, 5b, locking components, and round hole sockets 10a, 10b , Flexible metal strips 11a, 11b and so on.

[0021] The screening test object is the quartz tuning fork gyro meter 1, which is installed on the meter mounting bracket 12 through the locking assembly.

[0022] The tooling shell structure 2 and the cover plate 3 are connected through gluing process or screw locking, and the tooling is connected with the external installation base through the shell structure 2 .

[0023] Described table head mounting bracket 12 such as figure 1 As shown, the damping components 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com