Electrospray on-orbit detection method of colloid electric propulsion system and application thereof

A detection method and electrospray technology, which are applied in the direction of material analysis, measuring device, and instrument by electromagnetic means, to achieve the effects of strong practical prospects, increased volume, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

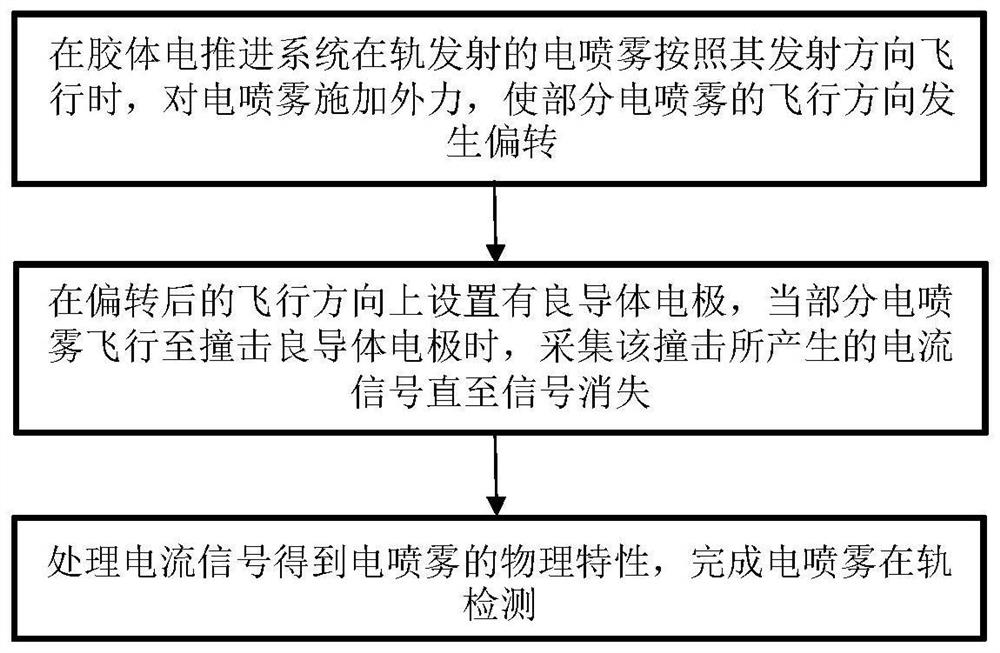

[0040] An electrospray on-orbit detection method of a colloidal electric propulsion system, such as figure 1 shown, including:

[0041] When the electrospray launched by the colloidal electric propulsion system flies in the direction of its launch, an external force is applied to the electrospray to deflect the flight direction of part of the electrospray;

[0042] A good conductor electrode is provided in the deflected flight direction, and when part of the electrospray flies to hit the good conductor electrode, the current signal generated by the impact is collected until the signal disappears;

[0043] The physical characteristics of the electrospray are obtained by processing the current signal, and the on-orbit detection of the electrospray is completed.

[0044] Among them, the collected current signal can be analyzed and processed by time-of-flight mass spectrometry to obtain the physical characteristics of the electrospray. In addition, the magnitude of the external ...

Embodiment 2

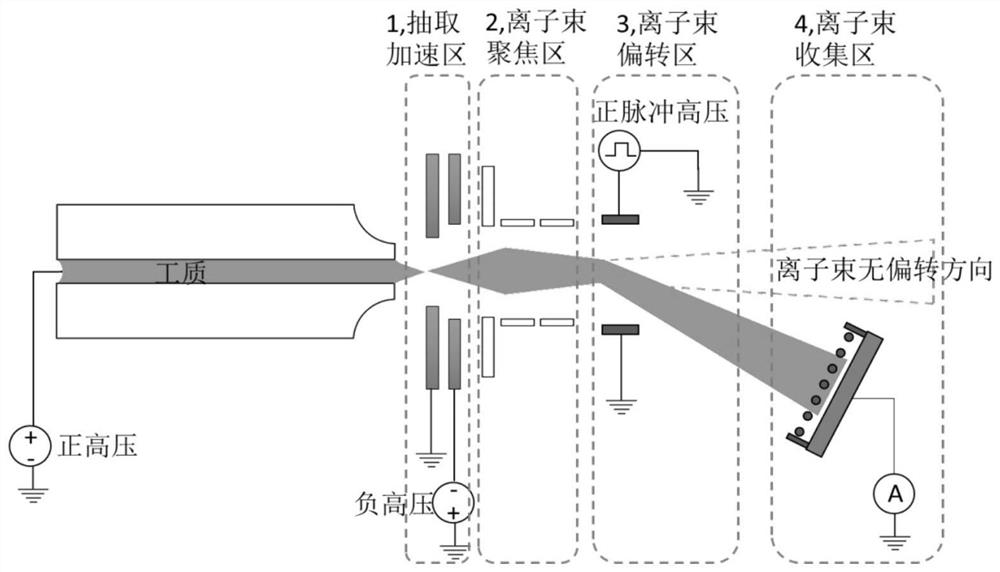

[0067] An electrospray on-orbit detection device for a colloidal electric propulsion system includes: a colloidal electric propulsion system to be tested, a deflection assembly, a good conductor electrode, a signal acquisition unit, and a signal processing unit. in,

[0068] The colloidal electric propulsion system to be tested emits electrospray in orbit; the deflection component is used to apply external force to the electrospray to deflect the flight direction of part of the electrospray; the good conductor electrode is set in the deflected flight direction for contact with part of the electrospray A collision occurs to generate a current signal; the signal acquisition unit is used to collect the current signal until the current signal disappears, and the signal processing unit is used to process the current signal to obtain the physical characteristics of the electrospray to complete the on-orbit detection of the electrospray.

[0069] Among them, the collected current sig...

example 1

[0077] Example 1: Implementation steps for detecting when the system is in continuous jetting mode of operation.

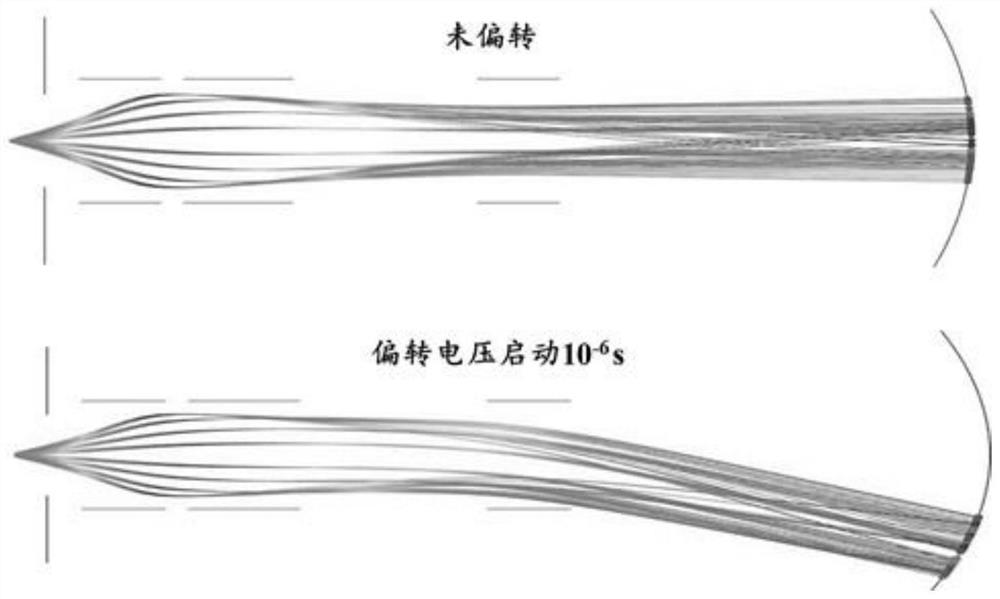

[0078] (1) At the initial moment, the deflection electrode and the Faraday cage are at zero potential, and maintain an equipotential state with the propulsion system shell, and the electrospray flies in the original direction at this time;

[0079] (2) The system control unit receives the detection instruction. When the deflection component is the deflection electrode, the control power supply system applies a pulse high voltage to the deflection electrode, and selects the appropriate pulse width according to the actual situation to deflect the electric field formed between the electrode plates; or when the deflection electrode When the component is an electromagnetic coil, the control power supply system supplies power to the electromagnetic coil to form a magnetic field. Finally, the electrospray flight direction between the plates or in the coil is deflected, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com