Low-temperature-drift relative plane mounting differential integrated resonant accelerometer

A surface mount, accelerometer technology, applied in the direction of measurement of acceleration, speed/acceleration/shock measurement, measurement device, etc., can solve the problem of inability to completely eliminate errors, reduce the basic accuracy of accelerometers, and difficult to implement the pressure-bonded gold wire micro-assembly process Increase and other problems to achieve the effect of reducing thermal stress, reducing difficulty, and small residual stress in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

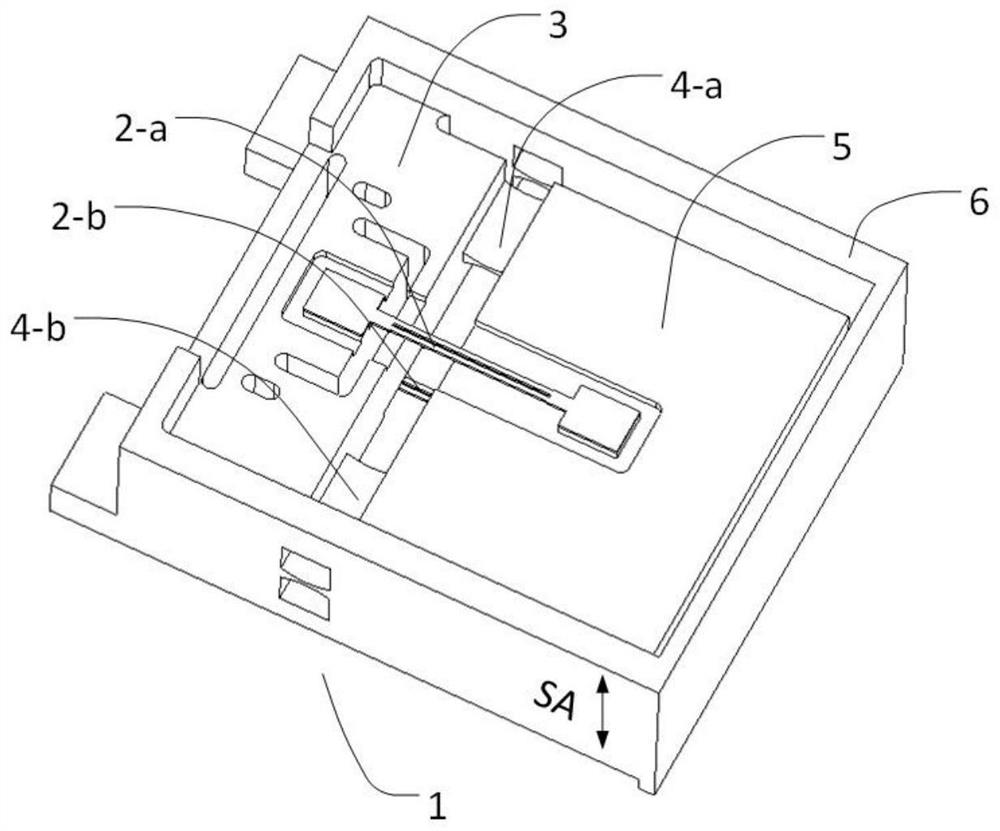

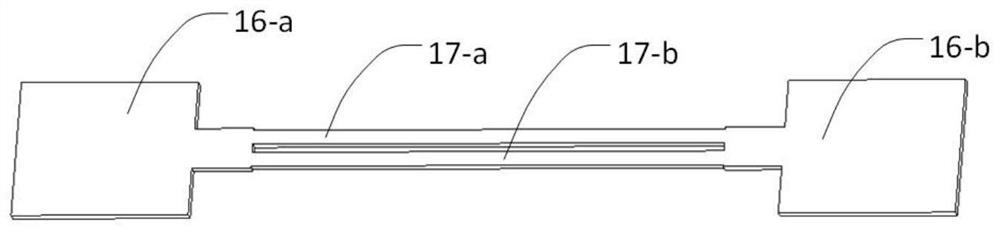

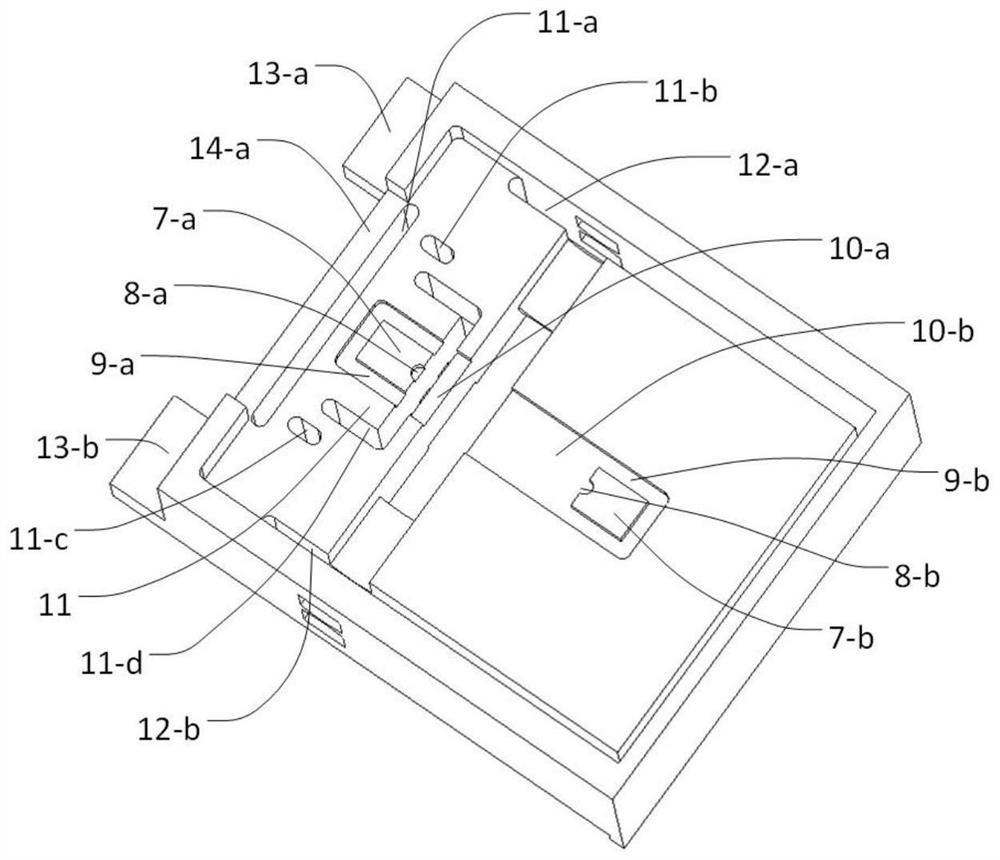

[0027] refer to figure 1 , a low-temperature drift relative plane mount differential type integrated resonant accelerometer, including a metal base 1 and a first double-end fixed support quartz tuning fork 2-a, a second double-end fixed support quartz tuning fork 2-b, and a metal base 1 Including a metal base 3, a first flexible hinge 4-a, a second flexible hinge 4-b, a mass block 5 and a metal frame 6, the mass block 5 passes through the first flexible hinge 4-a, the second flexible The hinge 4-b is connected to the metal base 3, and the left and right sides and the front side of the metal base 3 are connected to the metal frame 6; the first double-end fixed support quartz tuning fork 2-a and the second double-end fixed support quartz tuning fork 2 -b has the same structure, mounted on the front and back of the metal substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com