Quick response type recoverable fuse

A fast response, fuse technology, applied in electrical components and other directions, can solve the problems of large heat generation and long response time, and achieve the effect of shortening consumption time, reducing heat, and speeding up charging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

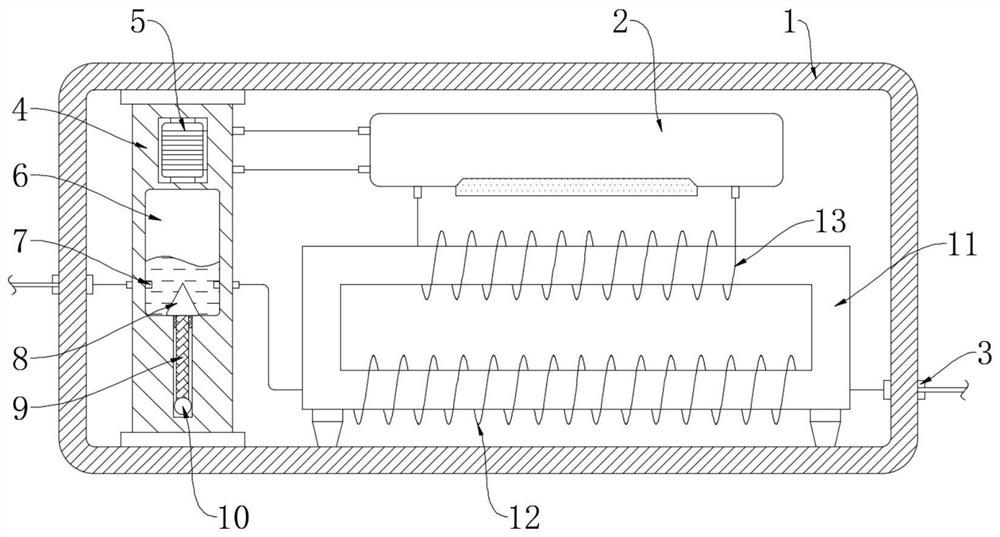

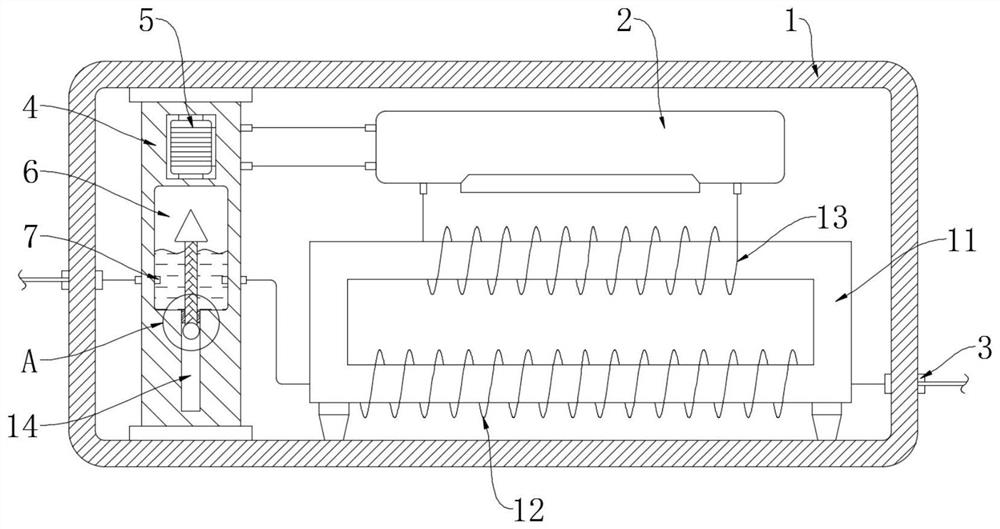

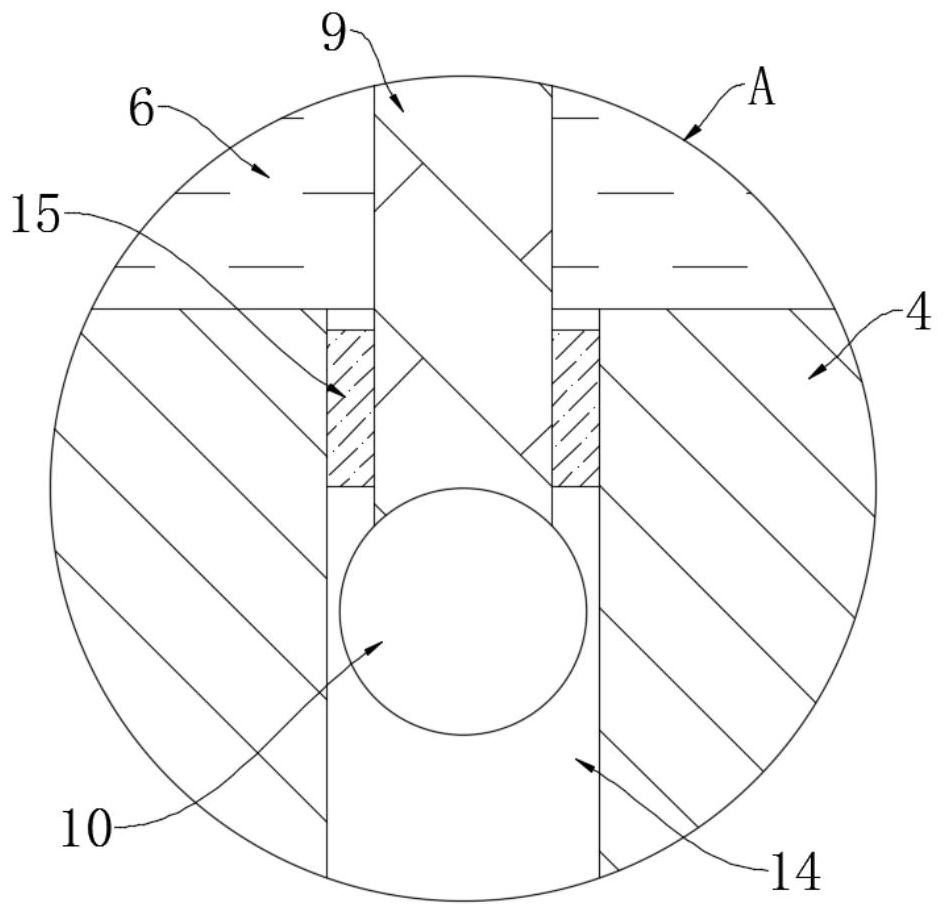

[0022] refer to Figure 1-3 , a fast-response resettable fuse, comprising an insulating case 1 and two terminals 3 fixedly installed on the insulating case 1, a circuit breaker 2, an insulating column 4 and an iron core 11 are fixedly arranged in the insulating case 1, A first coil 12 and a second coil 13 are wound in parallel on the iron core 11, and the second coil 13 is electrically connected to the converter 2, the first coil 12 and the second coil 13 are coupled to each other, and the two together form a set of mutual inductance Coil, the insulating column 4 is provided with a sealing groove 6 and a chute 14 that communicate with each other, and a sealing ring 15 is clamped at the connection between the chute 14 and the sealing groove 6, and the sealing ring 15 can prevent the conductive liquid from entering the chute 14, and the sliding A floating plate 9 is slidably arranged in the groove 14, and the upper end and the lower end of the floating plate 9 are respectively f...

Embodiment 2

[0034] refer to Figure 4 , the present embodiment differs from Embodiment 1 in that: a plurality of permanent magnets 16 are arranged horizontally in the circumferential direction of the insulating column 4, and each permanent magnet 16 is located below the sealing groove 6, and the polarity of the plurality of permanent magnets 16 The orientations are set to be the same, and a permanent magnet plate 17 is hermetically installed inside the floating block 8 , and the polarity orientation of the permanent magnet plate 17 is the same as that of the permanent magnet plate 16 .

[0035] In the use of this embodiment, the magnetic field force between the permanent magnet plate 17 and the permanent magnet 16 is greater than the magnetic field force between the counterweight 10 and the permanent magnet 16, and non-ferromagnetic materials can also be used to make the counterweight 10;

[0036] After the solenoid coil 5 is fed with electric current, the solenoid coil 5 can generate a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com