Three-phase motor with heat dissipation device

A heat dissipation device and technology for three-phase motors, applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problems of low heat dissipation efficiency and poor heat dissipation effect of three-phase motors, and achieve improved heat dissipation effect, improved heat dissipation efficiency, Guaranteed normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

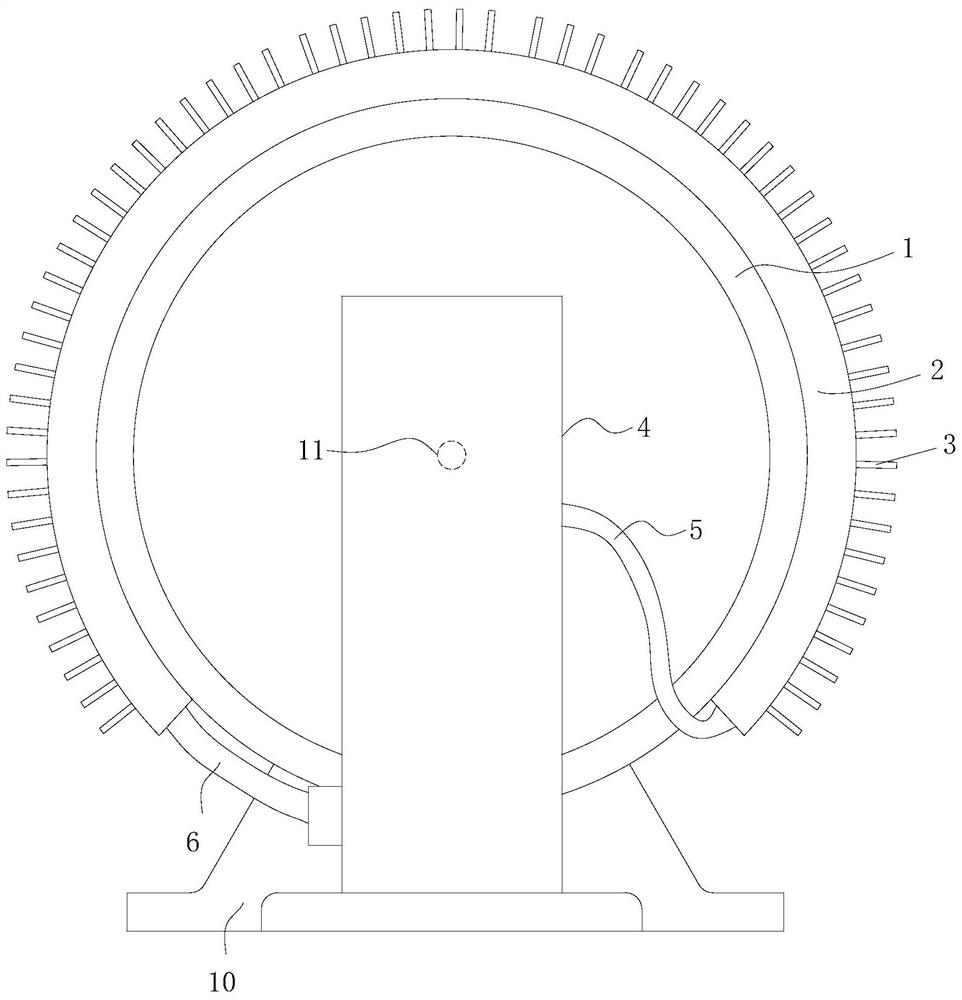

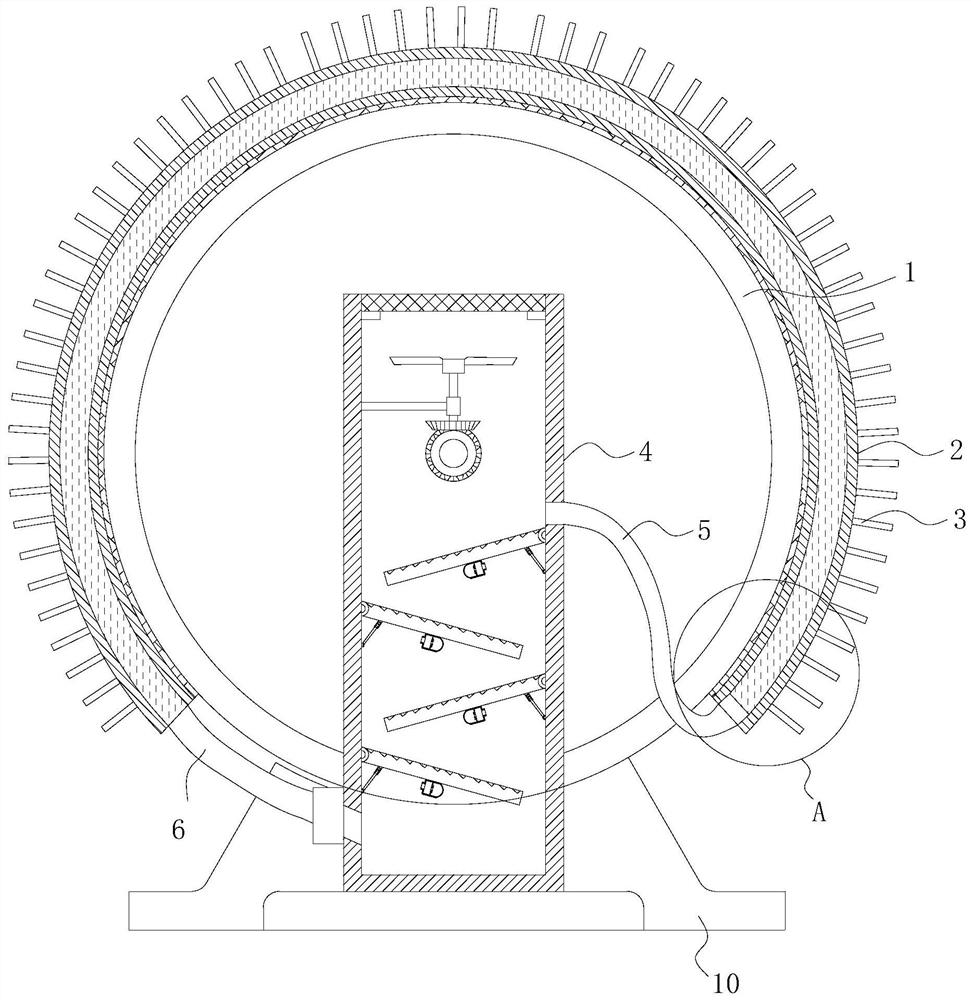

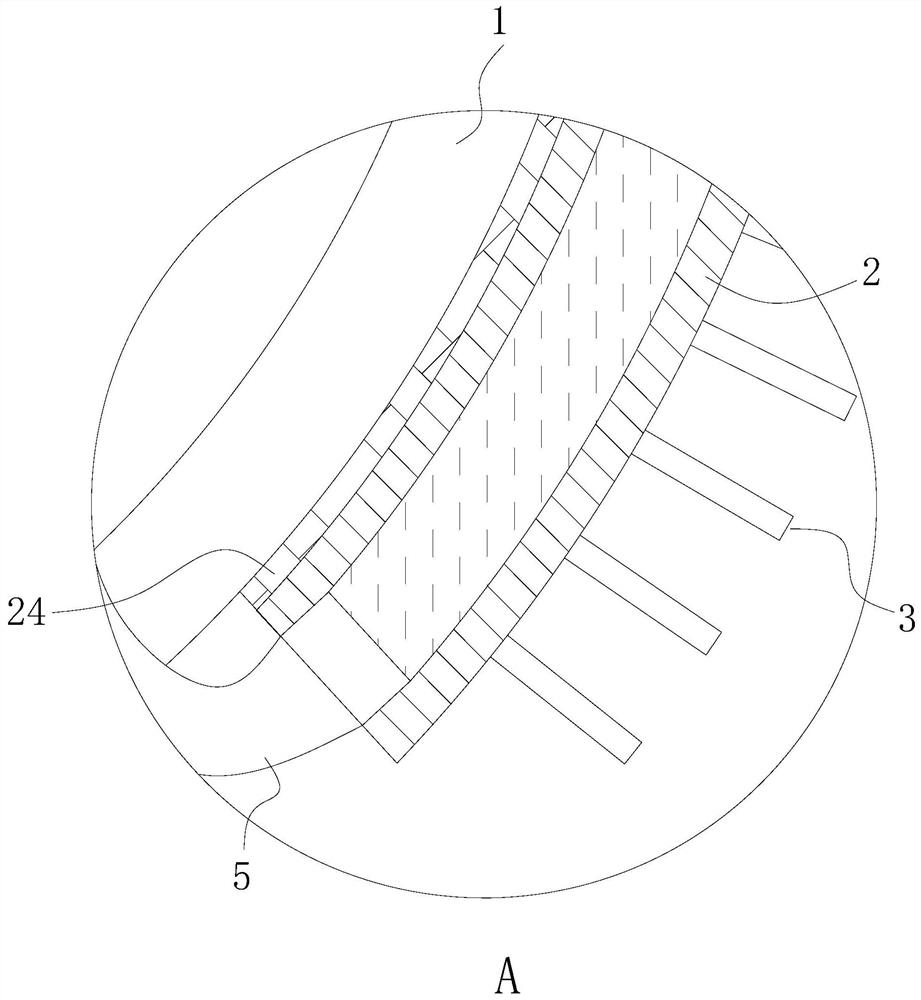

[0029] Please combine Figure 1 to Figure 7 , a three-phase motor with a cooling device, comprising a body 1 and a cooling device for cooling the body 1 . In this embodiment, the body 1 and the cooling device are installed on the base 10 . The base 10 can be an ordinary motor mounting frame to effectively support the body 1 . The heat dissipation device includes a heat exchange tank 2 and a water tank 4. The heat exchange tank 2 is fixed around the outer peripheral side of the body 1. In this embodiment, the side of the heat exchange tank 2 facing the body 1 as a whole is completely attached to the outside of the body 1 to cover the surface of the body. The heat dissipated in the heat-generating area is conducted to the inside of the heat exchange tank 2 . The heat exchange tank 2 can be fixed on the shell of the body 1 by screws, which is convenient for installation and disassembly. The side of the heat exchange tank 2 facing the body 1 is provided with a heat conduction l...

Embodiment 2

[0042] Please combine Figure 8 , this embodiment 2 is an improved solution of embodiment 1, specifically, the top of the deflector 8 is provided with a plurality of water blocking grooves 18 at equal intervals along its inclination direction, and the cross section of the water blocking groove 18 is a right triangle. The time for the water flow to pass through the top of the deflector 8 can be extended by the water blocking groove 18, and the water droplets in the water flow will splash when they flow out of the water blocking groove 18, so that the contact time between the water flow and the air becomes longer, and the cooling rate of the water flow is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com