Automatic indoor bean sprout cultivation equipment

A kind of equipment and technology of bean sprouts, applied in the agricultural field, can solve the problems of consuming time and energy of staff, increasing labor costs, etc., and achieve the effects of reducing burden, high degree of automation, and preventing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

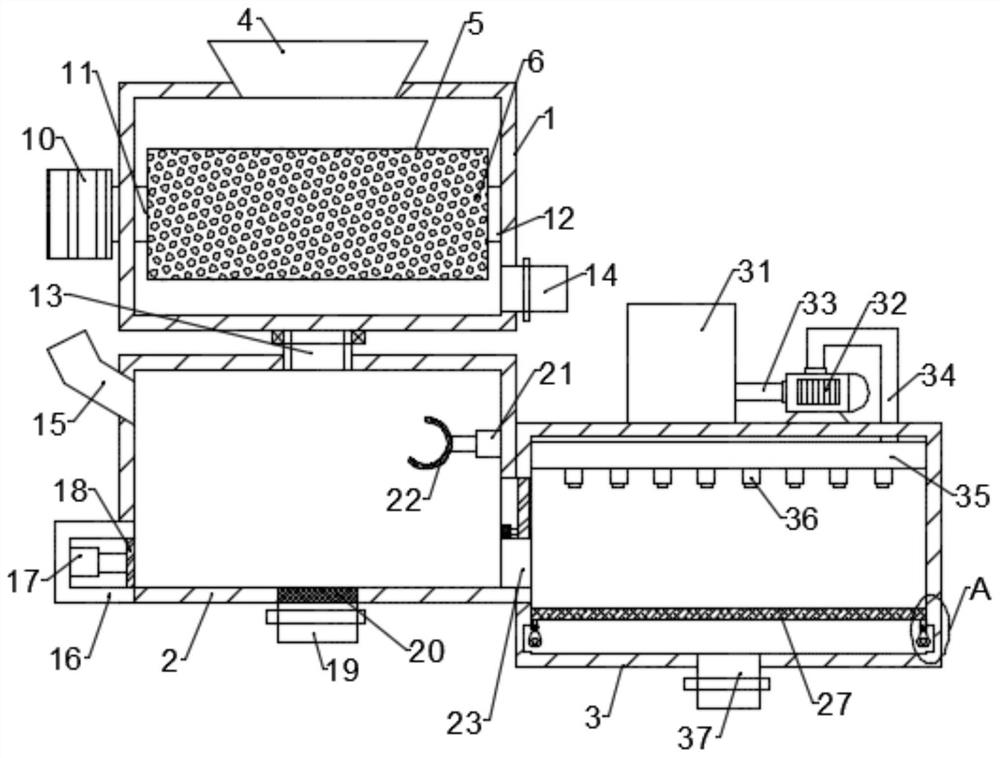

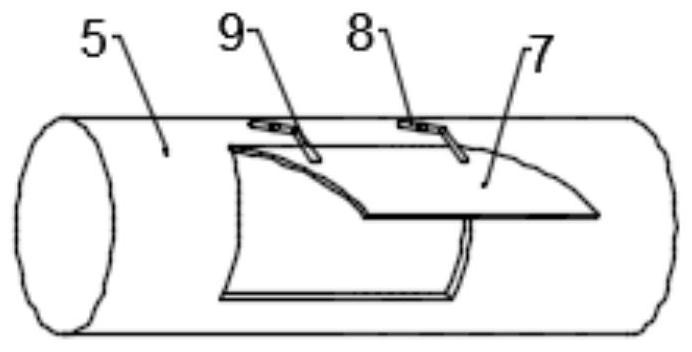

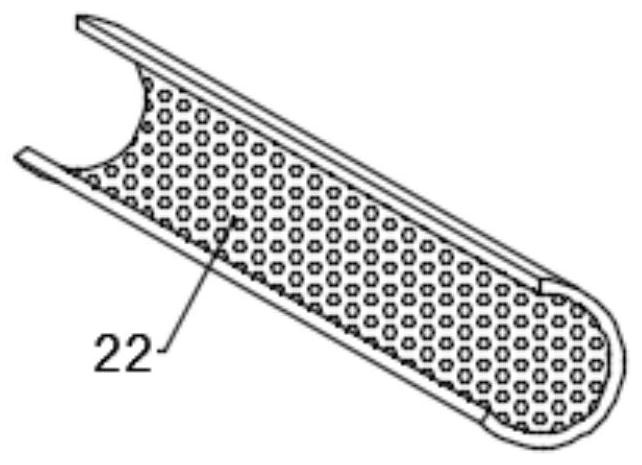

[0034] Such as figure 1 As shown, the embodiment of the present invention provides a kind of automation indoor bean sprouts cultivation equipment, described cultivation equipment comprises screening box 1, seed soaking box 2 and cultivation box 3, the bottom of described screening box 1 is connected with described The seed soaking box 2 is connected, and the side wall connected to the seed soaking box 2 and the incubation box 3 is provided with a discharge port 23, and the top of the discharge port 23 is provided with a rotating opening mechanism; the top of the screening box 1 is provided with an inlet Hopper 4, the bottom of screening box 1 is provided with first water outlet 14, and the inside of screening box 1 is equipped with rotating screening mechanism; Water outlet 19, the inside of seed soaking box 2 is provided with pusher mechanism corresponding to discharge port 23; The inside of described cultivation box 3 is provided with cultivation layer 27, and the bottom of ...

Embodiment 2

[0048] Such as Figure 6 As shown, in yet another embodiment provided by the present invention, the material leveling mechanism includes a cam 28, and a driven wheel 29 is arranged above the cam 28, and the driven wheel 29 is continuously meshed with the cam 28, and the driven wheel 29 A push rod 30 is fixedly connected to the bottom of the cultivation layer 27 outside.

[0049] Start the rotation of the cam 28, and when the cam 28 rotates to the upwards of the raised part, an upward impetus can be given to the driven wheel 29, thereby driving the cultivation layer 27 to move upward under the action of the push rod 30, the cam 28 continues to rotate, and the raised part gradually downwards, the upward force received by the driven wheel 29 gradually decreases, and it will gradually fall under the action of gravity, so that the cultivation layer 27 is pulled down by the push rod 30, and the continuous rotation of the cam 28 can continuously drive The cultivation layer 27 shakes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com