Mixer truck and using method

A mixer truck and mixing blade technology, applied to mixer accessories, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problem of difficult to achieve high combination of efficiency, results and cost, unable to meet demand, mixing The level is not high, and the construction effect is good, the construction speed is fast, and the mixing uniformity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

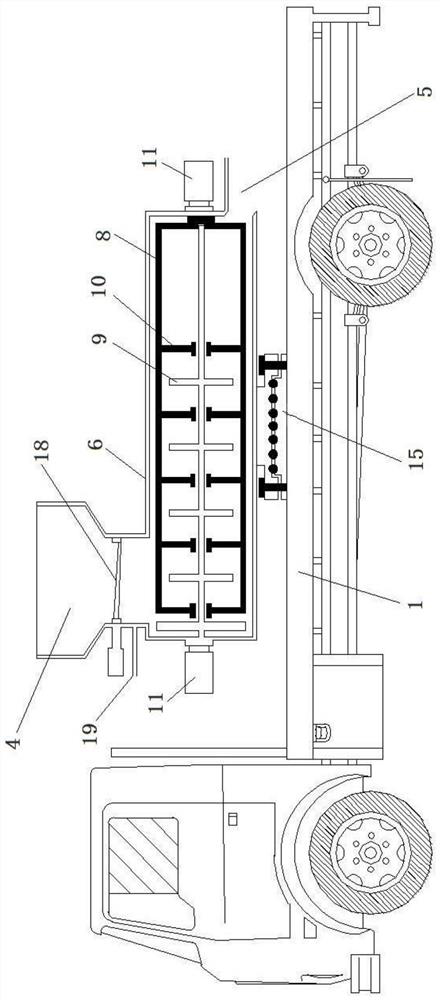

[0055] Embodiment 2: a kind of using method of mixer truck, it comprises the following steps:

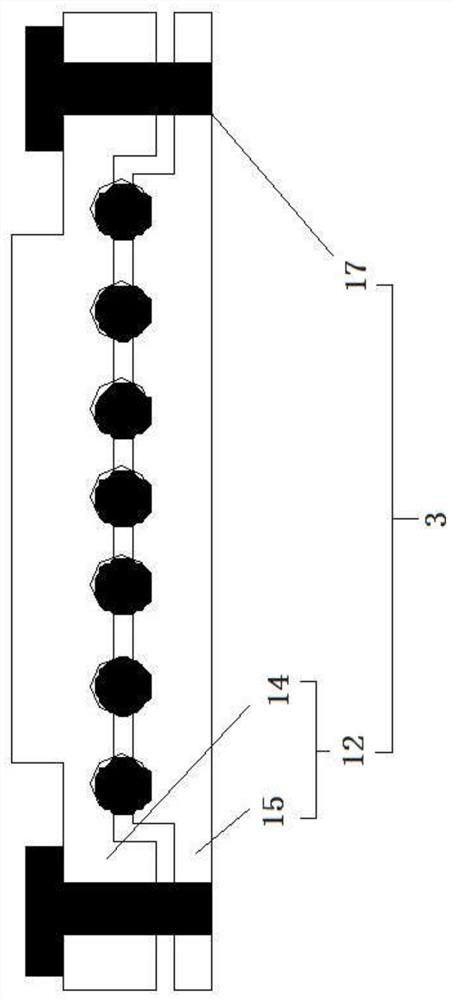

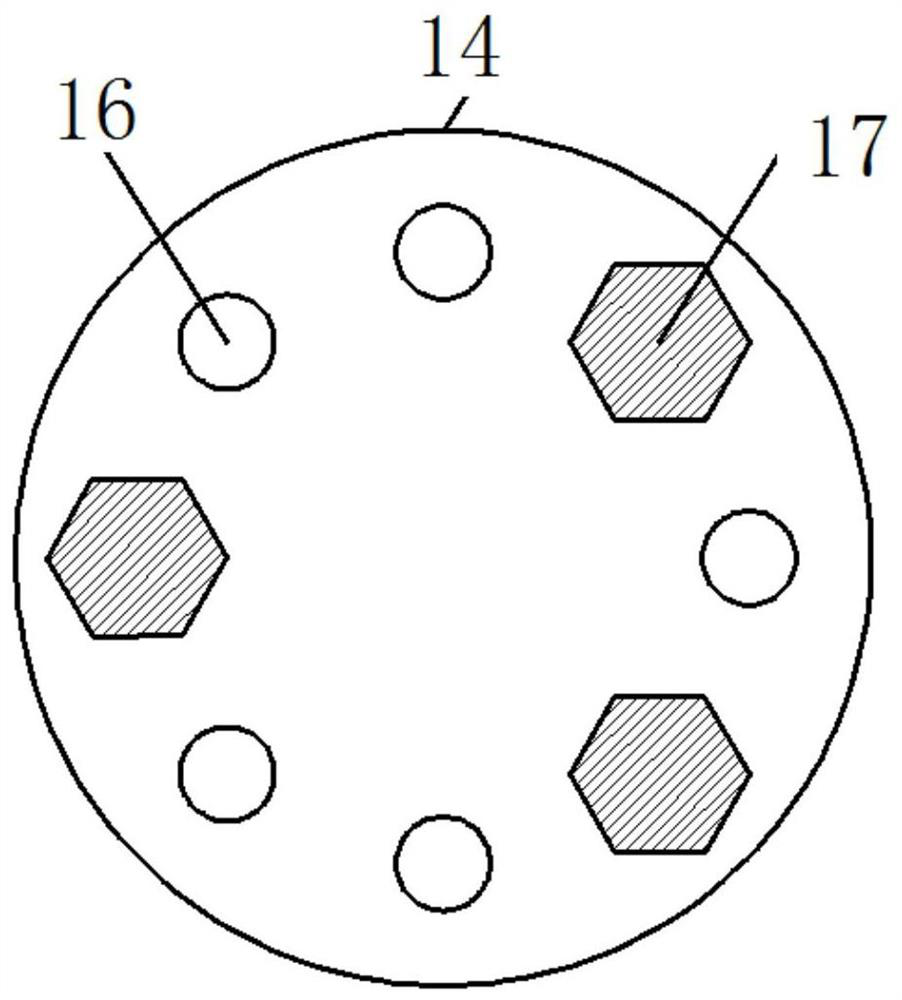

[0056] Step a: Start the construction vehicle body, move along the construction direction, adjust the shaft stirring blade and the frame stirring blade to the required angle and then fix it; generally, only two workers are required for the whole process;

[0057] Step b: After the construction vehicle body arrives at the construction site, turn the steering system to rotate the upper mixing system to the construction position, align the steering holes of the upper base of the bearing and the lower base of the bearing, insert the buckle, and place the two Lock and fix;

[0058] Step c: Align the discharge port directly above the construction site; feed the material from the hopper, start the mixing system for stirring; use iron plate traction transition between the discharge port and the construction site directly above, to facilitate the mixing Delivery of materials to the construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com