Chemical industrial raw material machining stirring device convenient to clean

A technology of stirring device and chemical raw materials, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve problems such as affecting the normal production and use of chemical raw materials, affecting the production quality of chemical raw materials, and residual raw materials, etc. Achieve the effect of improving mixing efficiency, high practicability and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

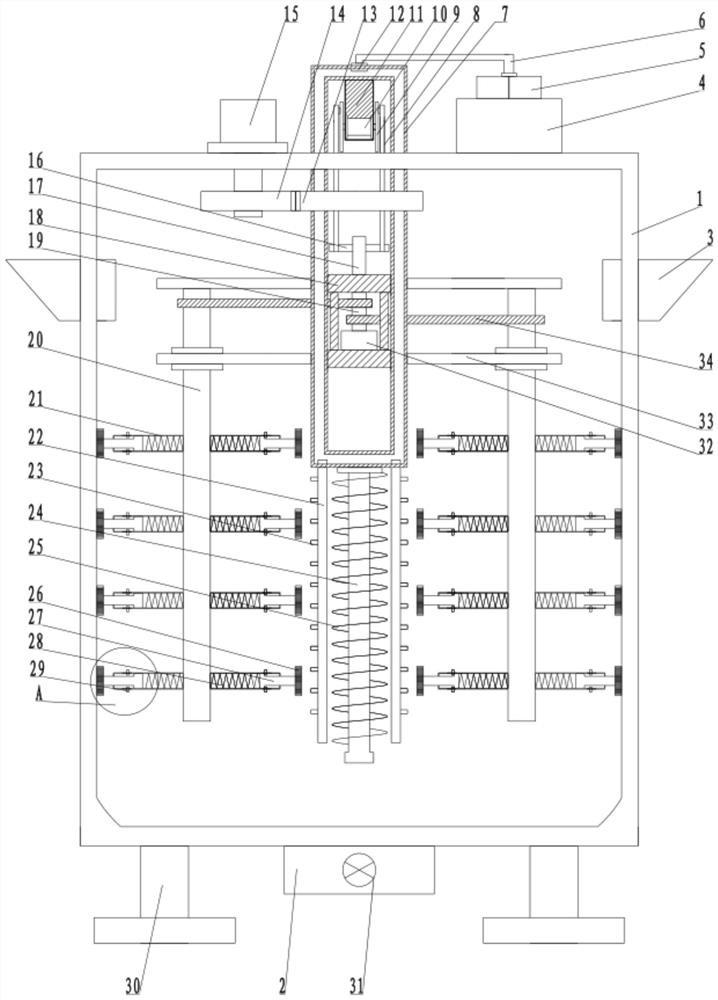

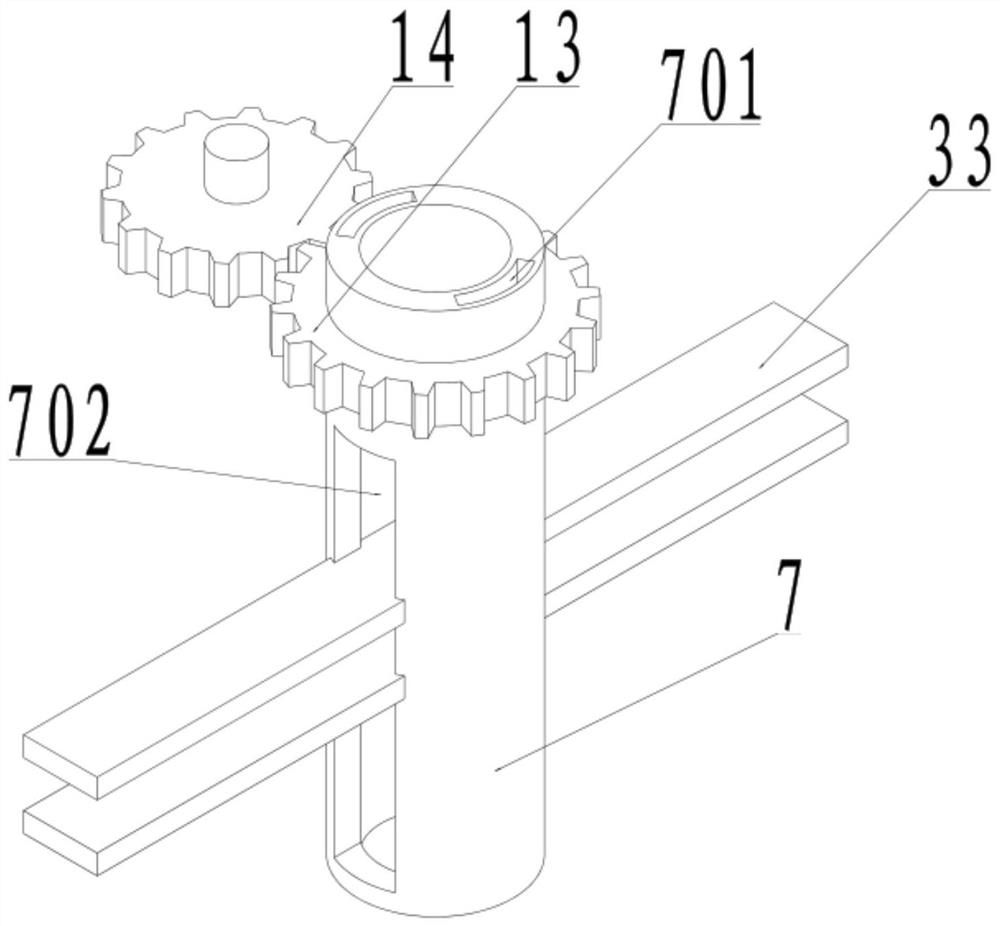

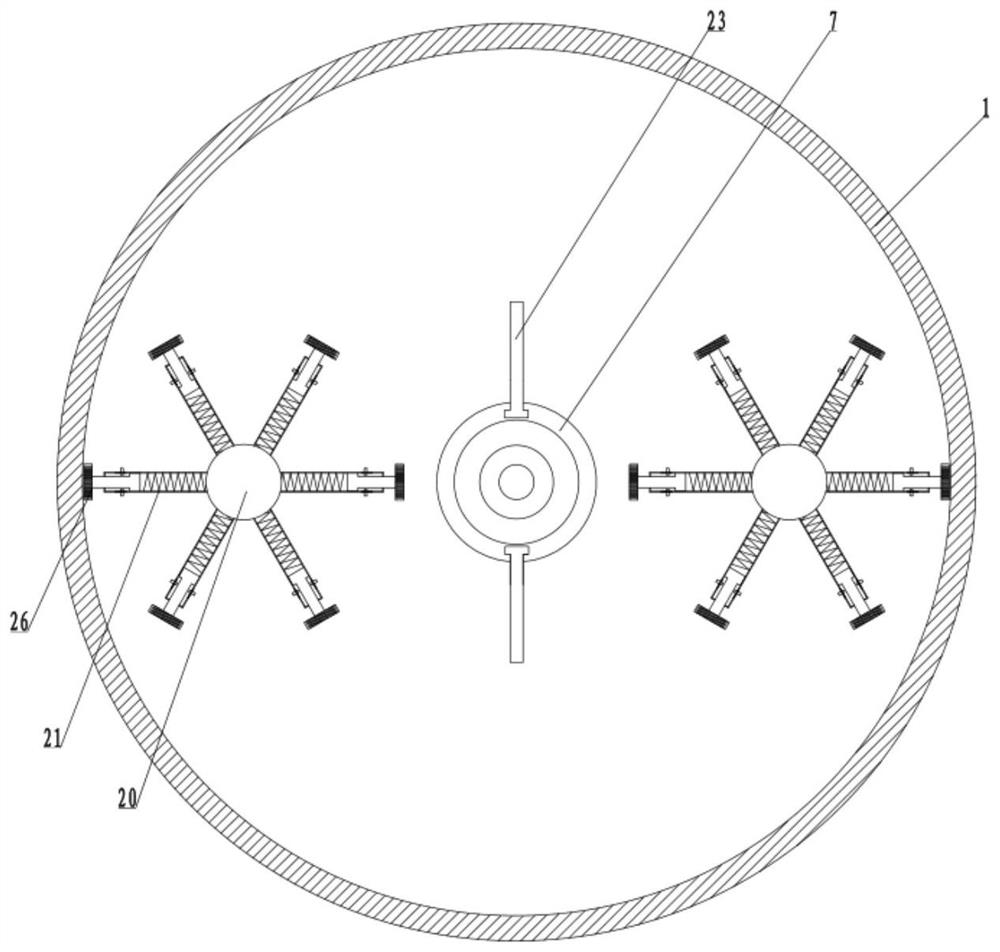

[0022] see Figure 1-4 , a stirring device for processing chemical raw materials that is easy to clean, comprising a stirring box 1, the top of the stirring box 1 is rotatably connected to an installation cylinder 7, the upper end of the installation cylinder 7 passes through the top wall of the mixing box 1, and extends to the top of the mixing box 1, The installation cylinder 7 is a cavity structure, and two sides are provided with through grooves 702. The inner top of the installation cylinder 7 is fixedly connected to the bearing block 11, and the outer sides of the bearing block 11 are connected to the transmission disc 9 in rotation, and the transmission disc 9 is far away from the bearing block 11. The drive rod 8 is hingedly connected to the disk surface on one side, and the installation shell 18 is fixedly connected in the installation cylinder 7 below the drive rod 8, and the installation block 17 is fixedly connected to the top of the installation shell 18, and the u...

Embodiment 2

[0029] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, except that the cleaning brush 26 is a brush made of corrosion-resistant material with low chemical activity.

[0030] During the implementation of the present invention, chemical raw materials are put into the mixing box 1 through the feed pipe 3 during use, and the transmission rod 8 is driven to reciprocate under the drive of the biaxial motor 10, and then the installation shell 18 below the transmission rod 8 is driven up and down. Move, the mounting rods 33 on both sides of the mounting shell 18 follow the mounting shell 18 to reciprocate up and down, while the stirring rod 20 on the mounting rod 33 drives the mixing drum 21 to rotate and stir under the action of the stirring motor 21, and at the same time, start the drive motor 15 , drive the installation cylinder 7 to rotate, and then drive the stirring rod 20 at the lower end to rotate in the mixing box 1 to further improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com