Vibration table for spheroidal graphite cast iron casting molding

A technology of nodular cast iron and vibrating table, which is applied to casting molding equipment, molding machines, and parts of molding machines. Simple, good shock absorption effect, not easy to damage the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

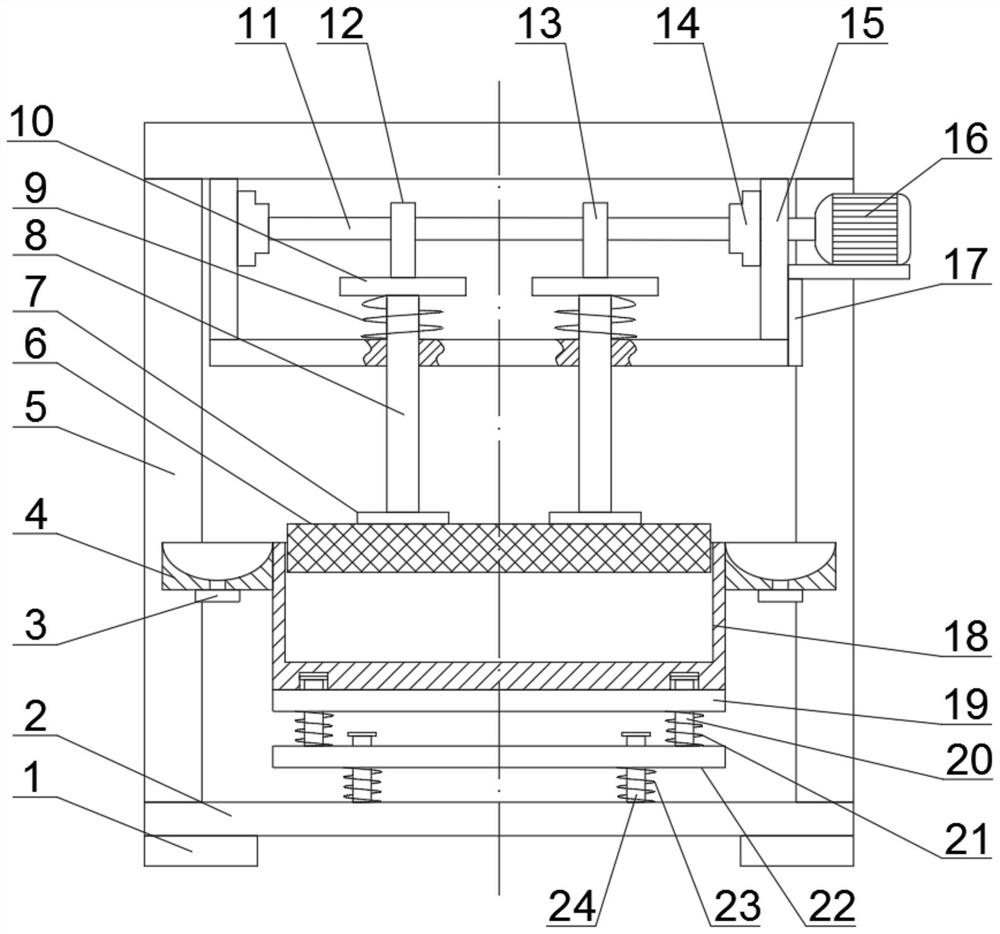

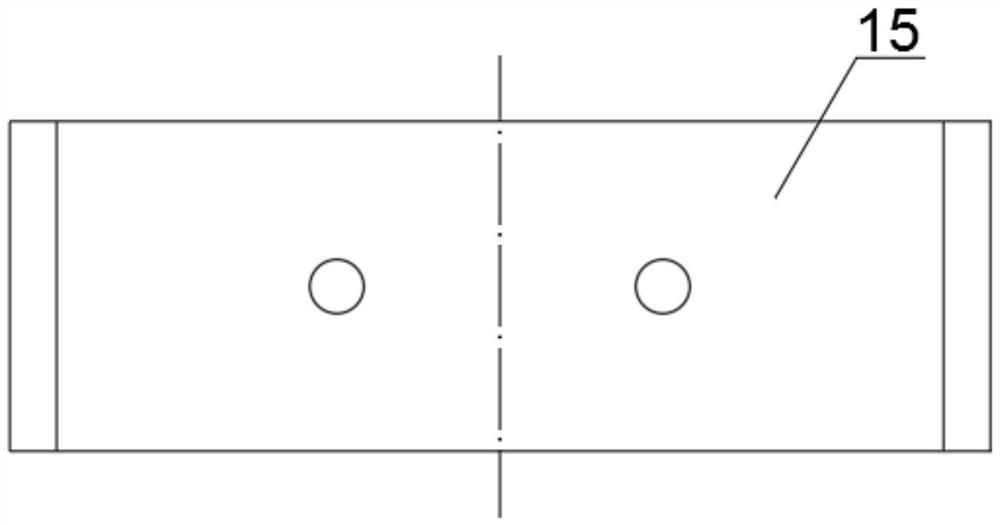

[0024] see Figure 1-3 , a vibrating table for modeling ductile iron castings, comprising a bottom plate 2, a support frame 5 is fixedly connected to both sides of the upper part of the bottom plate 2, a mounting seat 15 is fixedly connected to the bottom of the support frame 5, and a motor seat is fixedly connected to the right side of the mounting seat 15 17. A drive motor 16 is installed above the motor seat 17. The drive motor 16 is a geared motor with low vibration, low noise and good performance. The left side of the drive motor 16 is fixedly connected to a camshaft 11, and the camshaft 11 is connected to the Mounting seat 15 joint is fixedly connected with swivel seat 14, and described camshaft 11 is connected with swivel seat 14 in rotation, and described camshaft 11 middle left side is fixedly connected with first cam 12, and the right side of first cam 12 is installed with second camshaft. Cam 13, the first cam 12 and the second cam 13 are slidingly connected with a ...

Embodiment 2

[0026] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the lower part of the base plate 2 is fixedly connected with a kicker 1, and the kicker 1 heightens the distance between the base plate 2 and the horizontal plane, which is convenient for forklifts. Wait for it to be moved and transported.

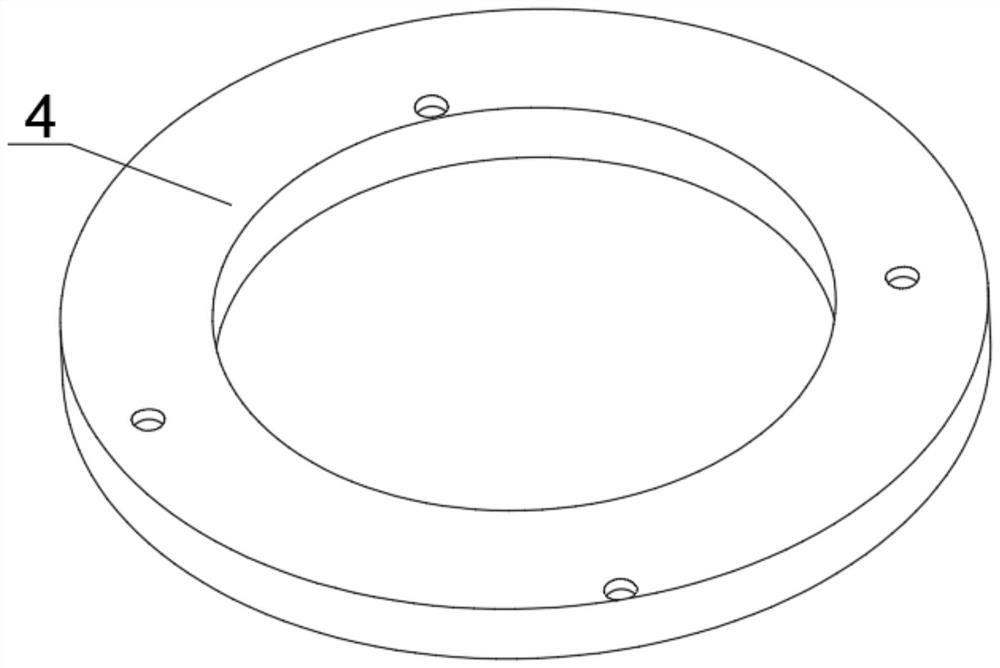

[0027] The working principle of the present invention is: the resin sand is poured into the casting box 18, and the driving motor 16 is started to drive the camshaft 11 to rotate, thereby driving the first cam 12 and the second cam 13 to rotate, so that the resin sand can be compacted by the pressing plate 6 , by arranging the second damping spring and the third damping spring, when the pressing plate 6 can squeeze the resin sand in the casting box 18, it can play the effect of damping and buffering, the damping performance is good, and it is not easy to damage the equipment; by setting the ring The colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com