Accurate degradation method of polyalkyne ester compound

A compound, polyalkynyl ester technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of high temperature catalyst effect, etc., and achieve the effect of simple degradation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

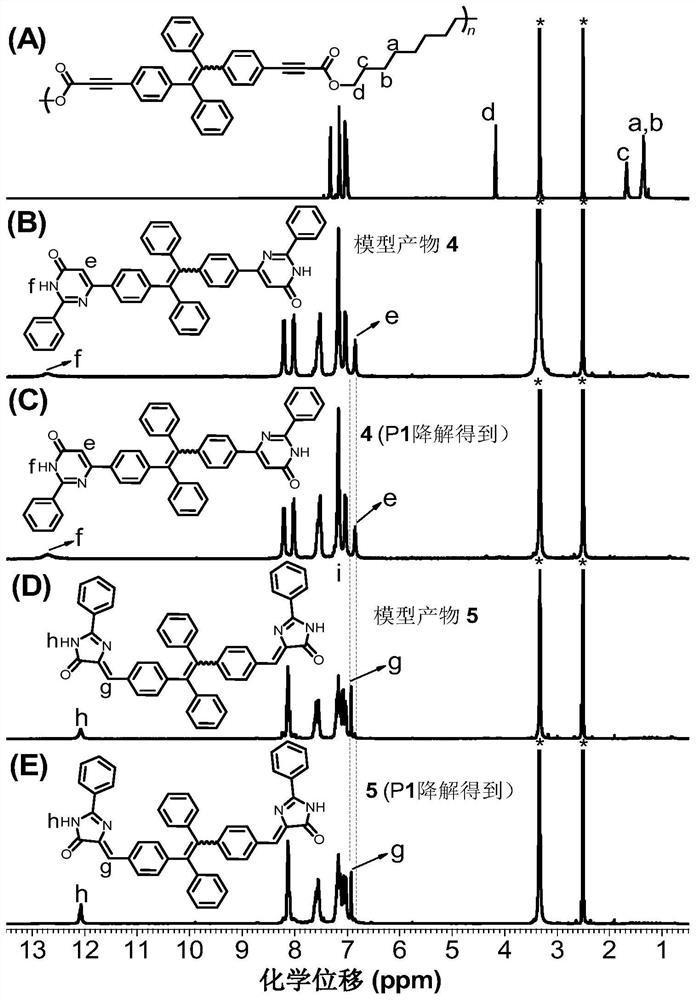

[0047] The polyalkyne ester compound P1 of the present embodiment, its structural formula is as follows:

[0048]

[0049] The above-mentioned polyalkyne ester compounds can be synthesized according to the synthesis method of the applicant in the authorized invention patent (patent number: ZL201610973824.6).

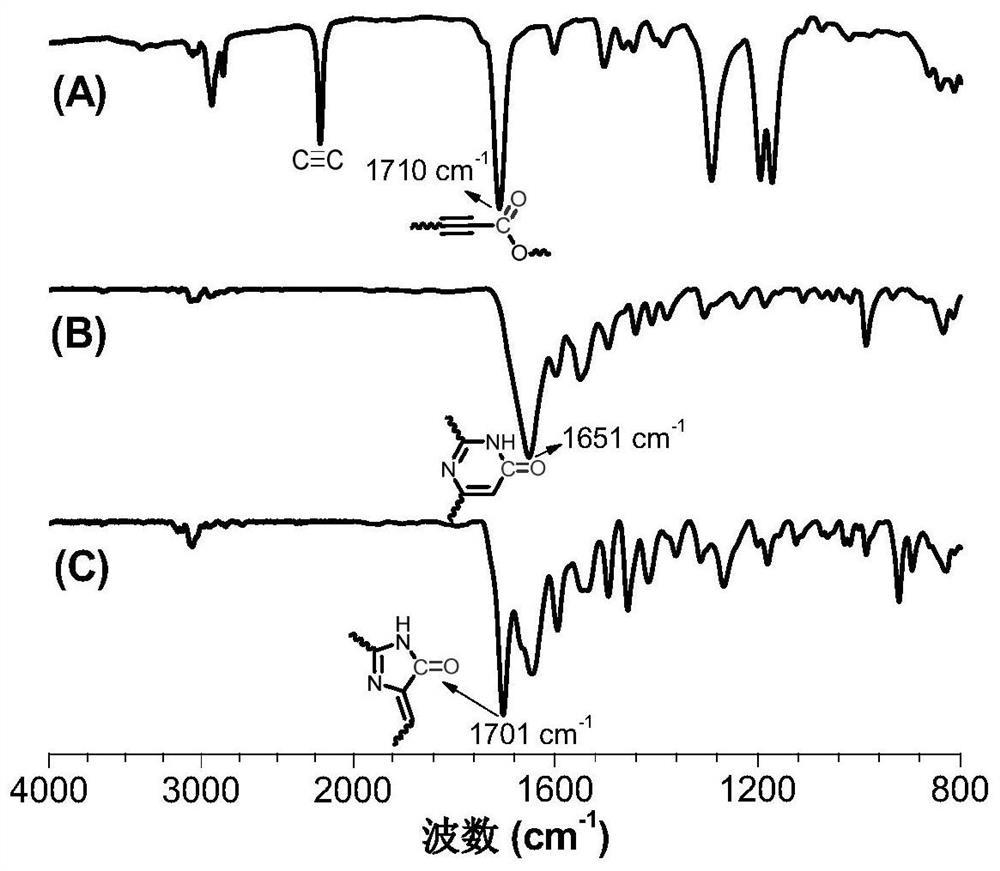

[0050] The reaction equation of the accurate degradation of the polyalkyne ester compound described in the present embodiment is as follows:

[0051]

[0052] Concrete preparation steps are as follows:

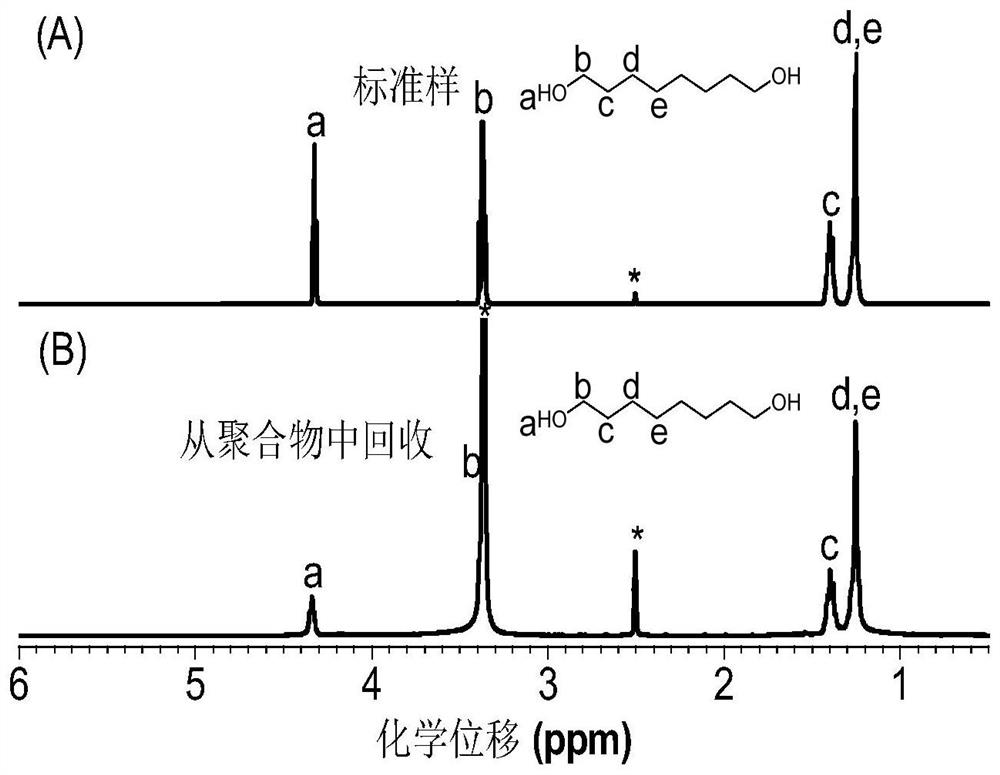

[0053] Add P1 (57.8mg, 0.1mmol, M w =80300g / mol,M w / M n =2.56), benzamidine (24.2mg, 0.2mmol), add toluene 1mL, at this moment, the degradation product obtained can be separated out easily, is convenient to just can purify by simple filtration and washing.

[0054] Route 1: react at 110°C for 12 hours, then cool to room temperature, filter and wash the precipitate with ethanol to obtain the degradation product pyrimidinone compound 4. The filtered solution wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com