A high-efficiency constant temperature semi-volume heat exchange unit

A volumetric, constant temperature technology, used in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of uneven hot and cold water, large labor and time consumption, and large floor space. , to achieve the effect of reducing labor costs, saving time, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

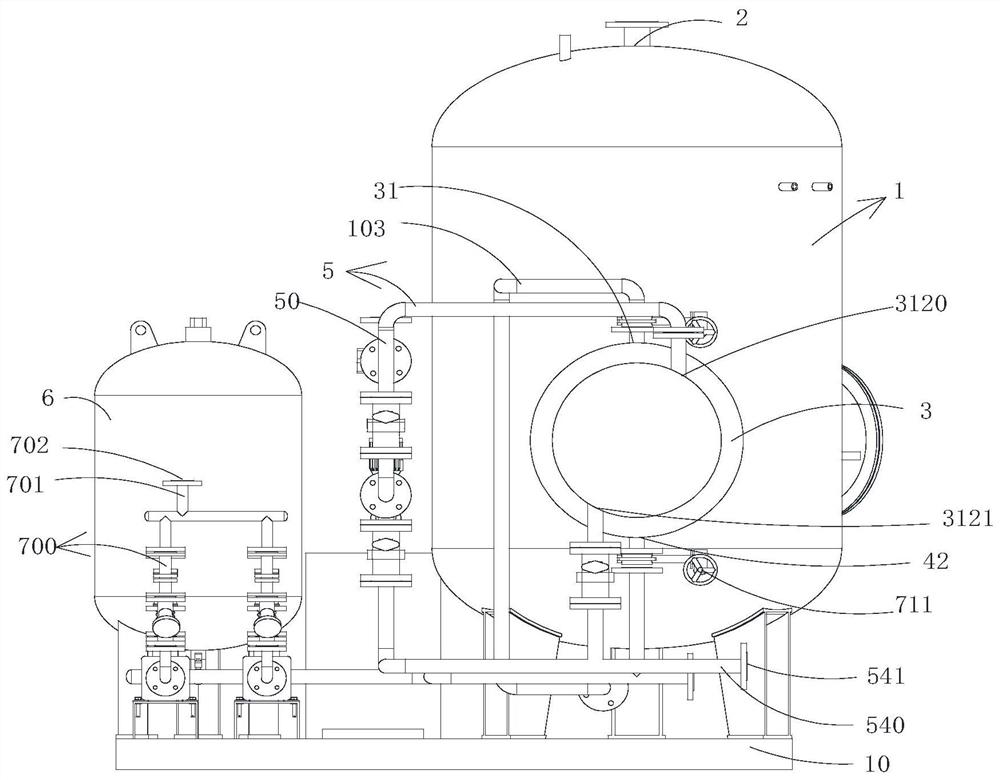

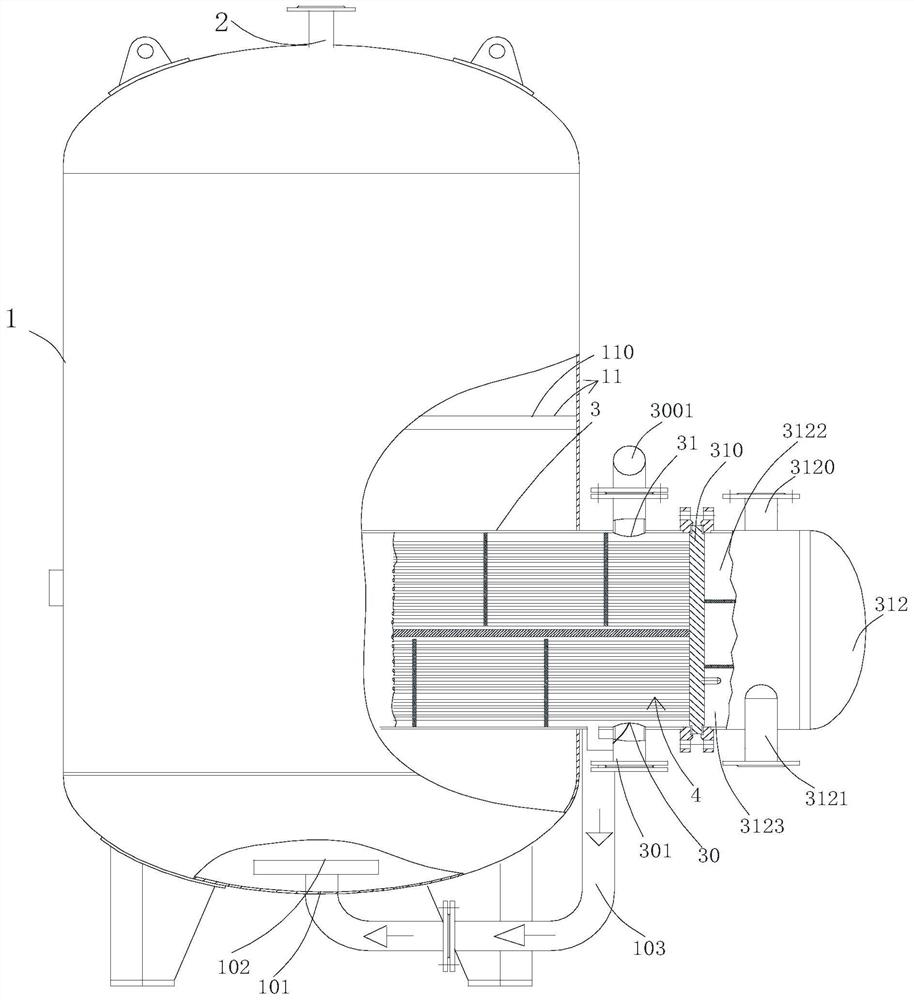

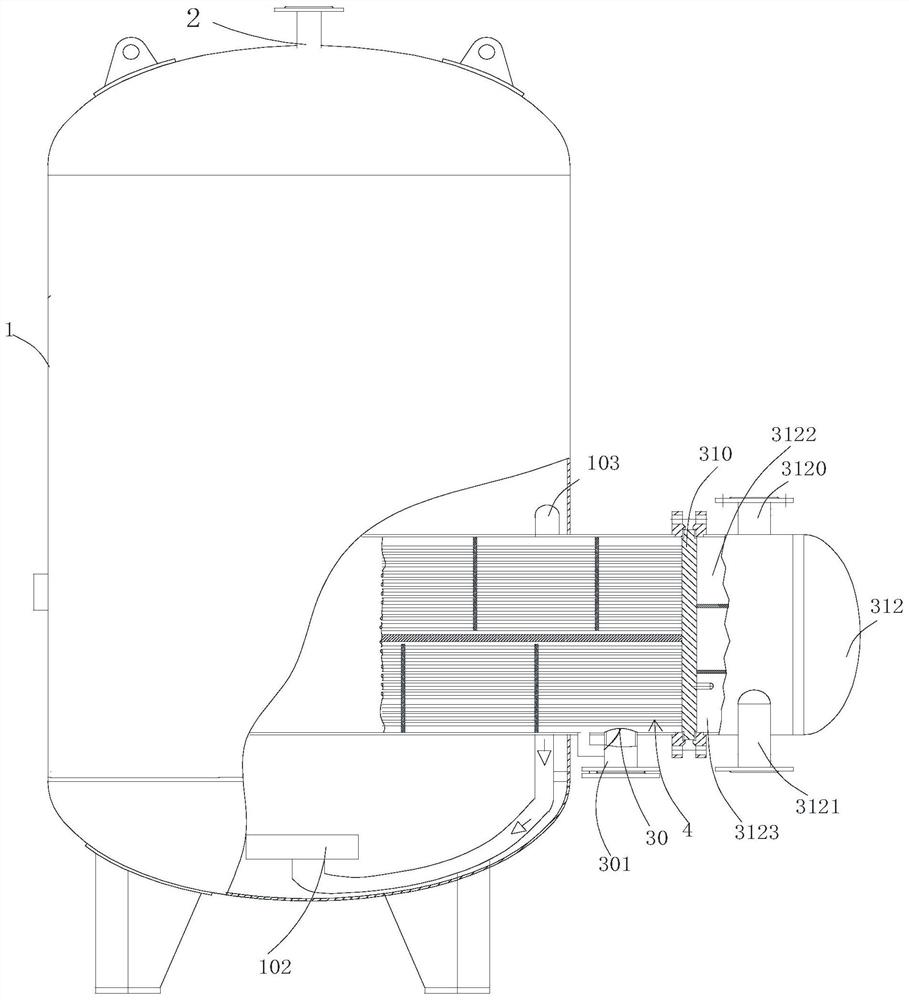

[0033] like Figure 1-16 A high-efficiency constant temperature semi-volumetric heat exchange unit shown in the figure includes at least one tank 1, a heat medium module 5, at least one expansion tank 6, a circulating pump 7 and a control module 8; the at least one tank 1, the heat medium module 5. At least one expansion tank 6, the circulating pump 7 and the control module 8 are integrated on a base 10; and the tank 1 and the expansion tank 6 in this embodiment are all set in one, by using the setting of the base 10, it is possible to The tank body 1, the expansion tank 6, the circulation module, the heat medium module 5 and the control module 8 are all formed on the base 10, which makes the structure more compact, the degree of automation is high, the layout is reasonable, the floor space is small, and the equipment maintenance more convenient.

[0034] Specifically, the tank body 1 includes an outlet 2 , a shell 3 , a heat exchange tube bundle 4 , a water inlet 30 and a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com