Efficiency measurement method of permanent magnet motor for ultra-high speed oil-free air compressor

A technology of air compressors and permanent magnet motors, which is applied in the direction of motor generator testing, measuring devices, power measurement, etc., and can solve the problem that air compressors cannot measure the efficiency of motors alone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

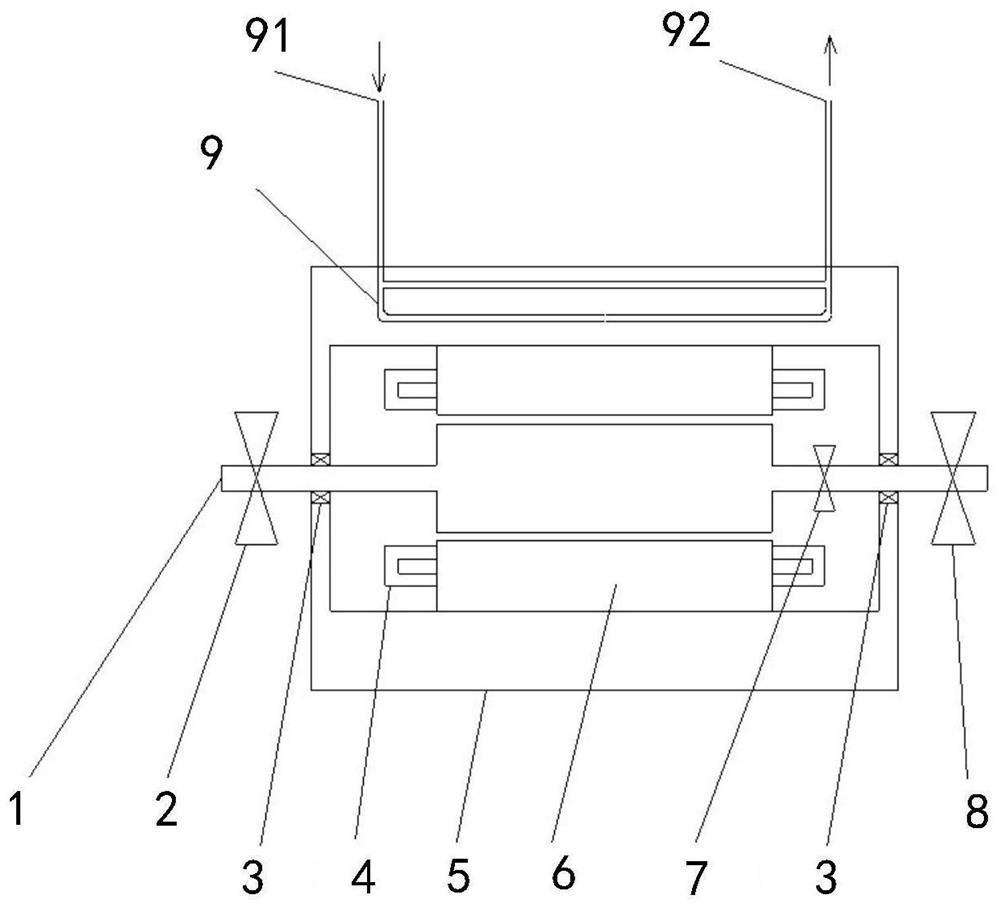

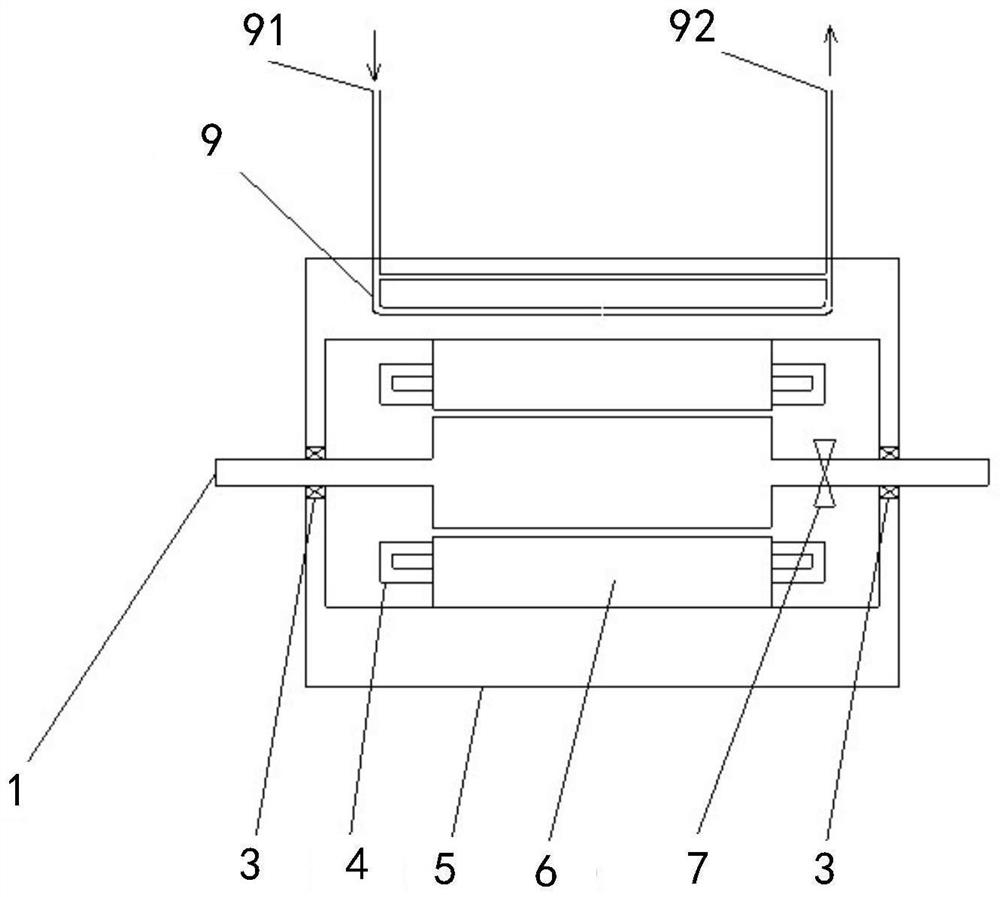

[0037] Such as figure 1 As shown, it is a structural schematic diagram of a permanent magnet motor for an ultra-high-speed oil-free air compressor provided by the present invention. A stator core 6 with a stator coil 4 is fixed on the inner wall of the casing 5, and a high-speed bearing is also passed in the casing 5. 3. The rotor 1 located at the center of the stator core 6 is installed. The two ends of the rotor 1 pass through the casing 5 and are respectively connected with the first-stage turbine 2 and the second-stage turbine 8. In the casing 5, there are also fixed rotor 1 The coaxial inner fan 7 on the top is used for heat dissipation;

[0038] A cooling waterway 9 is also provided in the casing 5, and the cooling waterway 9 can be arranged in the axial direction of the rotor 1, or arranged in a spiral shape. There is no specific limitation in the present invention, and the cooling waterway 9 is also provided with a water inlet 91 and a water outlet. 92.

[0039] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com