Device and method for detecting dust removal performance of cloth bag in coal-fired power plant

A technology for bag dust removal and coal-fired power plants, applied in measuring devices, by removing certain components for weighing, suspension and porous material analysis, etc., can solve the problem of inaccurate measurement of bag dust removal efficiency, and achieve rigorous and accurate test results. , The effect of optimizing detection conditions and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] Example.

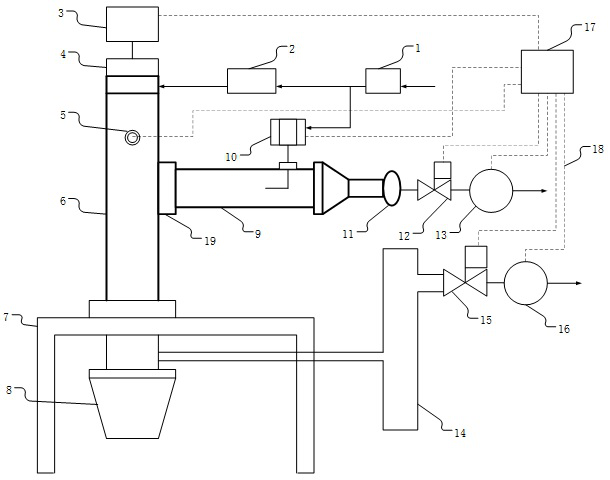

[0024] see figure 1 , in this embodiment, a device for detecting the bag dust removal performance in a coal-fired power plant is characterized in that it includes a temperature control system, a detection device and an intelligent control feedback system;

[0025] The temperature control system includes a filtering device 1 and a heating device 2;

[0026] The detection device includes a dust generator 3, an antistatic premixing device 4, an optical concentration detection device 5, a vertical dirty gas pipeline 6, a dust container 8, a horizontal clean gas pipeline 9, a compressed air cylinder 10, an absolute filter device 11, a first electromagnetic Valve 12, first air pump 13, dirty gas backup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com