Soybean cooling device for soybean paste production

A cooling device and soybean paste technology, applied in household refrigeration devices, applications, refrigerators, etc., can solve the problems of poor heat dissipation effect, low cooling efficiency, single cooling method, etc. The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

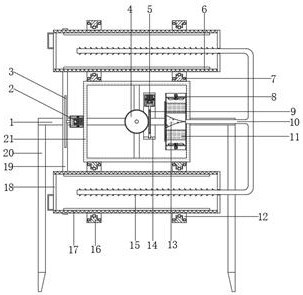

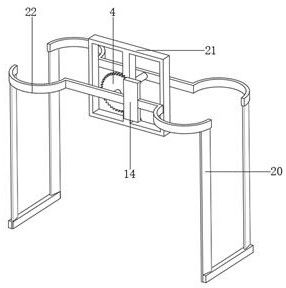

[0030] refer to Figure 1-4 , a soybean cooling device for soybean paste production, comprising two supports 1, the two ends of the supports 1 are provided with arc-shaped ends 22, and the bottom outer walls of the arc-shaped ends 22 are welded with supporting legs 20, the middle end of the supports 1 The rotating column is connected by bearing rotation, and one end of the rotating column is welded with a mounting frame 21, the ends of both sides of the mounting frame 21 are welded with fixed snap ring plates 16, and the inner sides of the fixed snap ring plates 16 are all provided with fixed ring plates 12. The same cooling net tube 17 is fixedly installed on the inner walls of the two fixed ring plates 12. The inner wall of one side of the installation frame 21 is fixed with a cooling box by bolts, and the upper and lower ends of the cooling box are provided with air inlets. The inner wall of the cooling box is fixed with a blower 8 by bolts, and there is an installation gro...

Embodiment 2

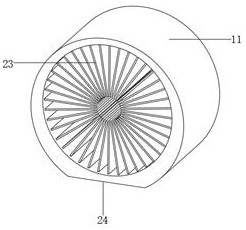

[0041] refer to Figure 5 , a kind of soybean cooling device for soybean paste production. Compared with Embodiment 1, this embodiment also includes that the heat exchange air cylinder 11 is provided with circular passages 25 distributed in an equidistant ring, and the circular passages 25 are all provided with strips. Shaped air grooves 26, both sides of the heat exchange fins 23 are provided with strip-shaped arc grooves 27 distributed equidistantly.

[0042] When the present invention is used: use the mutual cooperation between the circular through groove 25 and the strip-shaped air groove 26 arranged on the heat-exchanging air cylinder 11, and the strip-shaped arc groove 27 arranged on the heat-exchanging fin 23 to effectively increase the heat exchange air cylinder. 11 of the heat exchange area, thereby improving the heat exchange and cooling effect of the air, so as to achieve the purpose of further improving the cooling efficiency of soybeans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com