Chinese chestnut steaming plant

A cooking device and technology for chestnut, which are applied in food processing, food forming, food science and other directions, can solve the problems of uneven cooking, difference, insufficient cooking of chestnut at the top, etc., to ensure the cooking effect, improve the feeding efficiency, improve the The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

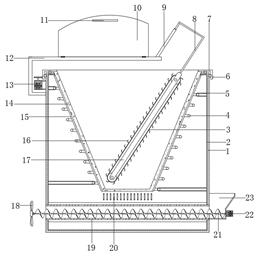

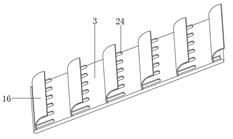

[0029] refer to Figure 1-4 , a chestnut cooking device, comprising a main housing 1, the top of the main housing 1 is rotatably connected to a cooking tank 14, the top of the cooking tank 14 is welded with a flange 7, and the flange 7 is opposite to the main housing 1 A drive mechanism is installed on one side, and an installation substrate 12 is welded on one side of the outer wall of the main housing 1, and the end of the installation substrate 12 is fixed with a hydraulic rod 9 that is inclined to be installed by bolts, and the end of the hydraulic rod 9 is fixedly installed with an L-shaped Rod frame 8, and the end of L-shaped rod frame 8 is welded with the frame frame 17 that is inclined with cooking tank 14 inner walls, and the two ends of frame frame 17 are all connected with roller body by bearing rotation, and the outer wall cover of roller body The same transmission belt 3 is connected, and the outer wall of the transmission belt 3 is fixedly equipped with equidista...

Embodiment 2

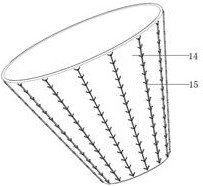

[0040] refer to Figure 5 , a chestnut cooking device. Compared with Embodiment 1, this embodiment also includes that the outer wall of the cooking tank 14 is provided with concave strip grooves 27 interlaced with fishbone tendon rods 15, and the concave strip grooves 27 that are provided can cooperate with fish Bone tendon rod 15, to reach the effect of improving the heating effect of cooking tank 14 to the greatest extent.

[0041] When the present invention is in use: the sunken bar groove 27 provided can cooperate with the fishbone tendon rod 15 to maximize the heating effect of the cooking tank 14, so as to achieve the purpose of improving the cooking effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com