A chemical engineering production boiler

A technology for chemical engineering and boilers, which is applied in the field of boilers for chemical engineering production, can solve the problems of general heat utilization effect and reduced heat exchange effect, and achieve the effects of avoiding blockage, ensuring combustion treatment, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

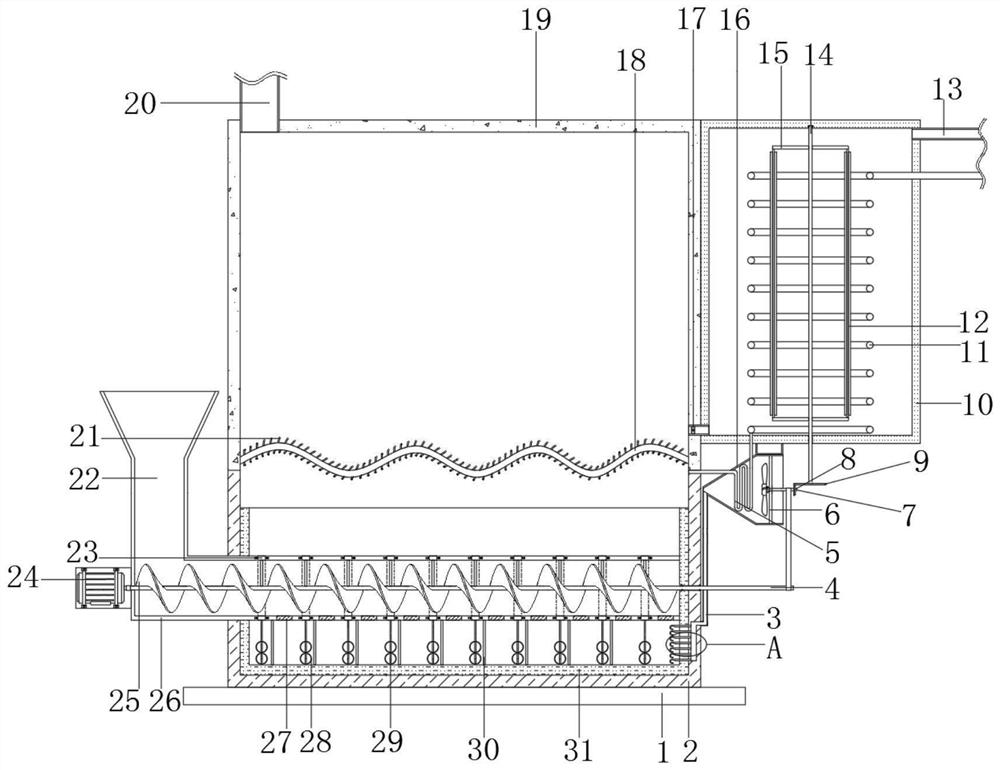

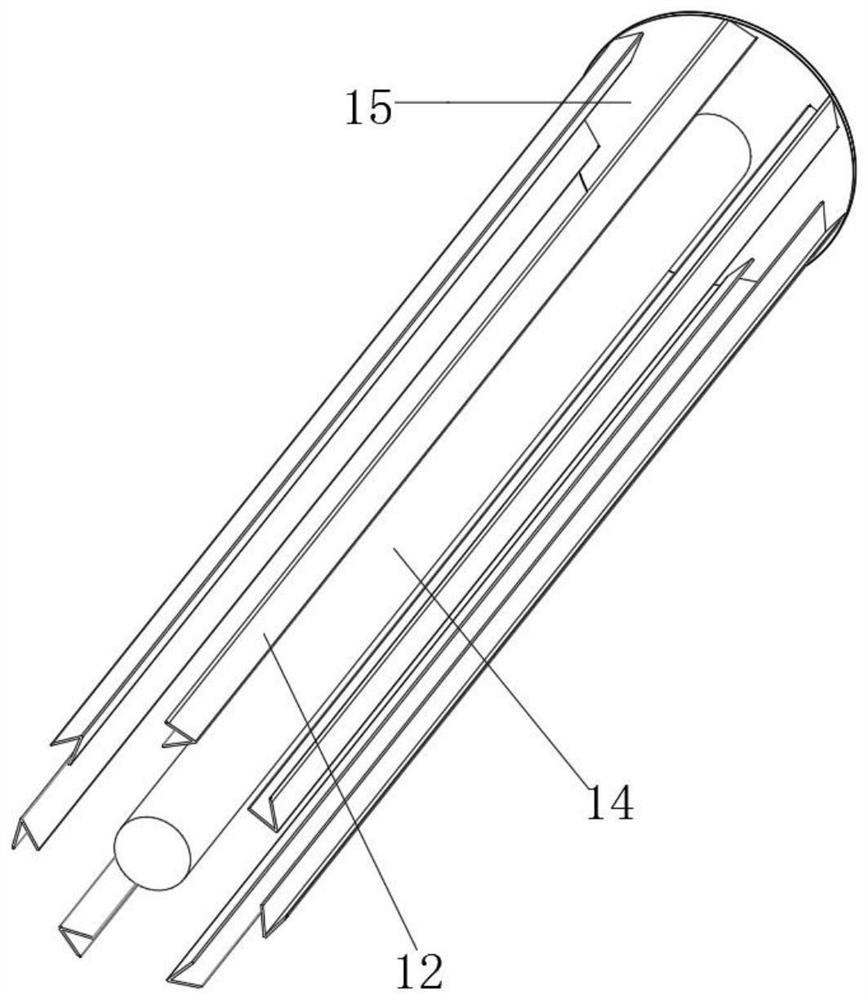

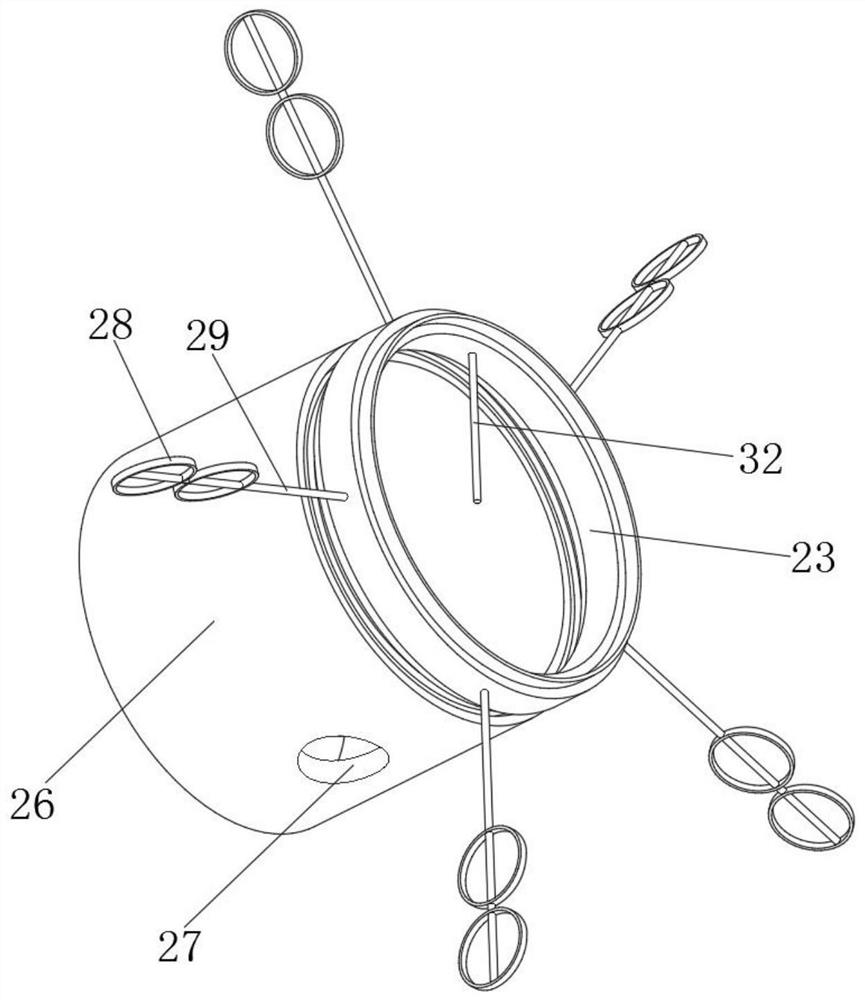

[0032] refer to Figure 1-6, a boiler for chemical engineering production, including a base plate 1, a combustion bottom 2 is welded on the top outer wall of the base plate 1, and a furnace body 19 is welded on the top of the combustion bottom 2, and a heat-resistant inner bottom is arranged on the inner bottom of the combustion bottom 2 Layer 31, the furnace body 19 and the opposite side of the combustion bottom 2 are welded with the same heat exchange bottom plate 18, and the section of the heat exchange bottom plate 18 is a waveform, and one end of the combustion bottom 2 is equipped with a feeding mechanism, and the feeding mechanism includes welding On the feeding end cylinder 26 of the combustion bottom 2, the opposite side of the feeding end cylinder 26 and the heat-resistant inner layer 21 are solidly welded with fixed struts 30 distributed equidistantly, and the feeding end cylinder 26 is opened with a cross section of the fixed struts 30. The ring slots of the distri...

Embodiment 2

[0043] refer to Figure 7 , a boiler for chemical engineering production. Compared with Embodiment 1, this embodiment also includes that the opposite side of the driven end column 14 of the base plate and the corner piece 12 are welded with connecting pieces 39 distributed equidistantly, and the connecting piece 39 One end has a through hole, and the inner wall of the through hole is welded with a bucket-shaped end pipe 38; the connecting piece 39 and the bucket-shaped end pipe 38 arranged on the opposite side of the driven end column 14 and the angle piece 12 can effectively improve the angle. The liquid-repelling effect of the sheet 12, and the bucket-shaped end pipe 38 can produce a narrow pipe effect, further increasing the flow rate of the water liquid.

[0044] When the present invention is in use: the connecting piece 39 and the bucket-shaped end pipe 38 arranged on the opposite side of the driven end column 14 and the angle piece 12 can effectively improve the liquid-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com