Microbial fermentation equipment for sludge treatment

A technology of microbial fermentation and sludge treatment, applied in the direction of biological sludge treatment, etc., can solve the problems such as the inability to mix the sludge evenly, the sludge is not effectively fermented, etc., and achieve the effect of uniform fermentation treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

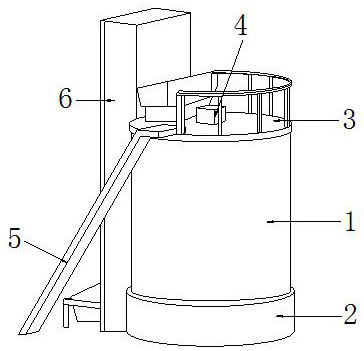

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of technical scheme of microbial fermentation equipment for sludge treatment:

[0028] Such as Figure 1-Figure 2 As shown, a microbial fermentation equipment for sludge treatment, its structure includes a fermentation tank 1, a power drive chamber 2, a heat insulation cover 3, a uniform stirring device 4, an escalator 5, and a feeding rack 6. The power drive chamber 2 Installed on the lower surface of the fermenter 1, the heat insulating cover 3 is arranged on the upper surface of the fermenter 1, the uniform stirring device 4 is arranged inside the fermenter 1, and the top end is exposed to the air through the heat insulating cover 3, The end of the uniform stirring device 4 located inside the fermenter 1 is matched with the power drive chamber 2, the escalator 5 is inclined to match the fermenter 1, and the feeding rack 6 is vertically installed on the left side of the fermenter 1. On the ot...

no. 2 example

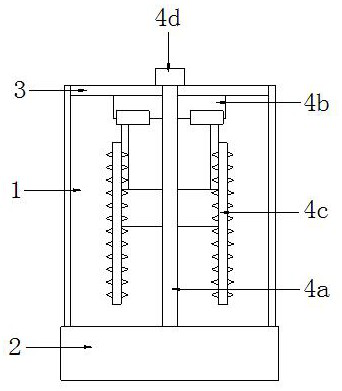

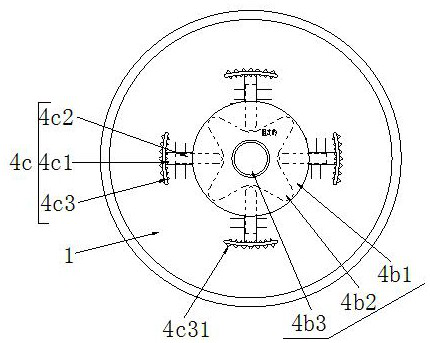

[0038] Such as Figure 4 As shown, the present invention provides a kind of technical scheme of microbial fermentation equipment for sludge treatment:

[0039] Such as Figure 4 As shown, a microbial fermentation equipment for sludge treatment, its structure includes that the inside of the rotating rod 4a is a hollow structure, which is respectively matched with the air flow box 4d and the oxygen filling part 4c1, and the air flow inside the air flow box 4d is outward flow.

[0040] Such as Figure 4 As shown, the oxygen charging part 4c1 includes a shaft plate 4c11, a limit spring 4c12, a permeation hole 4c13, and a scraper rod 4c14. The shaft plate 4c11 is welded through the rotating rod 4a. Inside the plate 4c11, the penetration holes 4c13 are densely distributed on the surface of the shaft plate 4c11 and are an integrated structure, and the scraper rods 4c14 are distributed on the outer surface of the shaft plate 4c11 and connected vertically, which is beneficial to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com