High-precision blade coating equipment and method with adjustable blade coating angle

A high-precision, angle-adjustable technology, used in devices and coatings that apply liquid to surfaces, and can solve the problems that restrict the performance improvement and commercial application of OFET devices, uneven microstructure arrays, and large thickness of coating materials. , to speed up the preparation, improve the blade coating process, and reduce the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

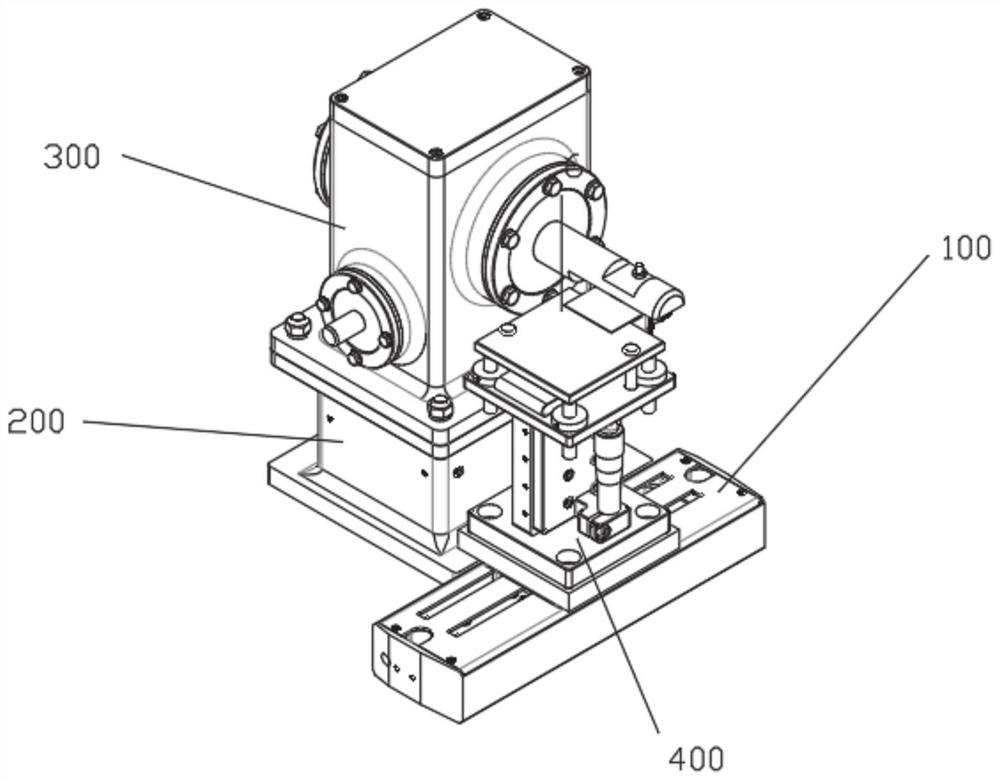

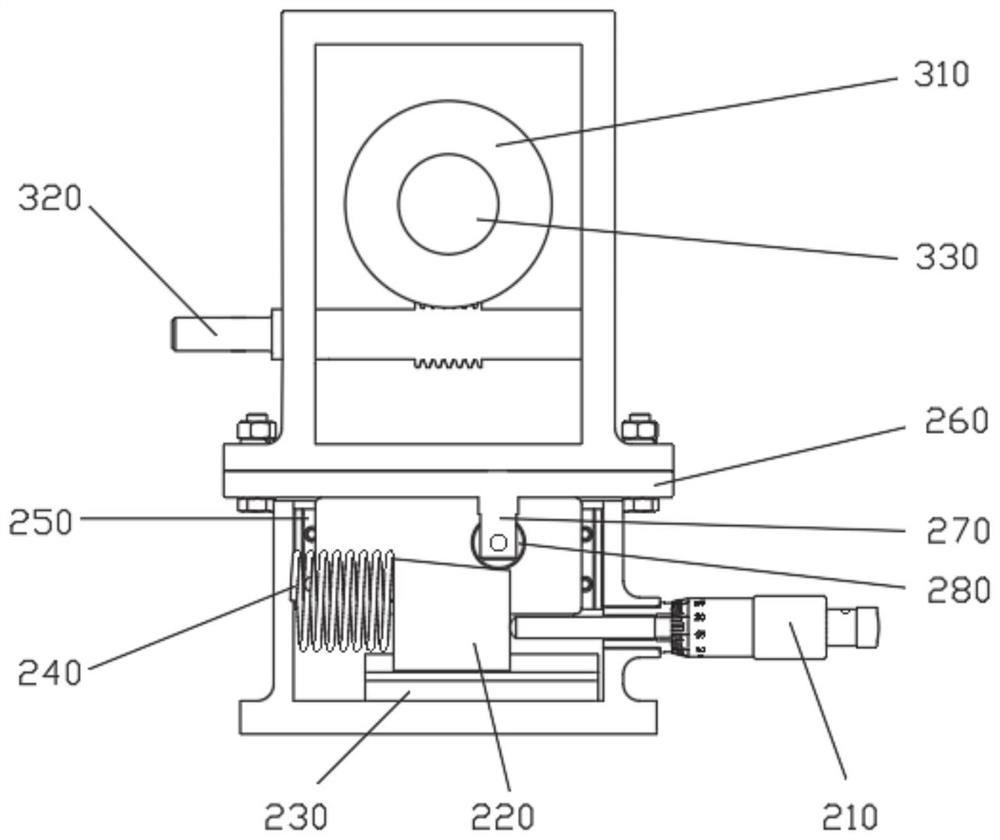

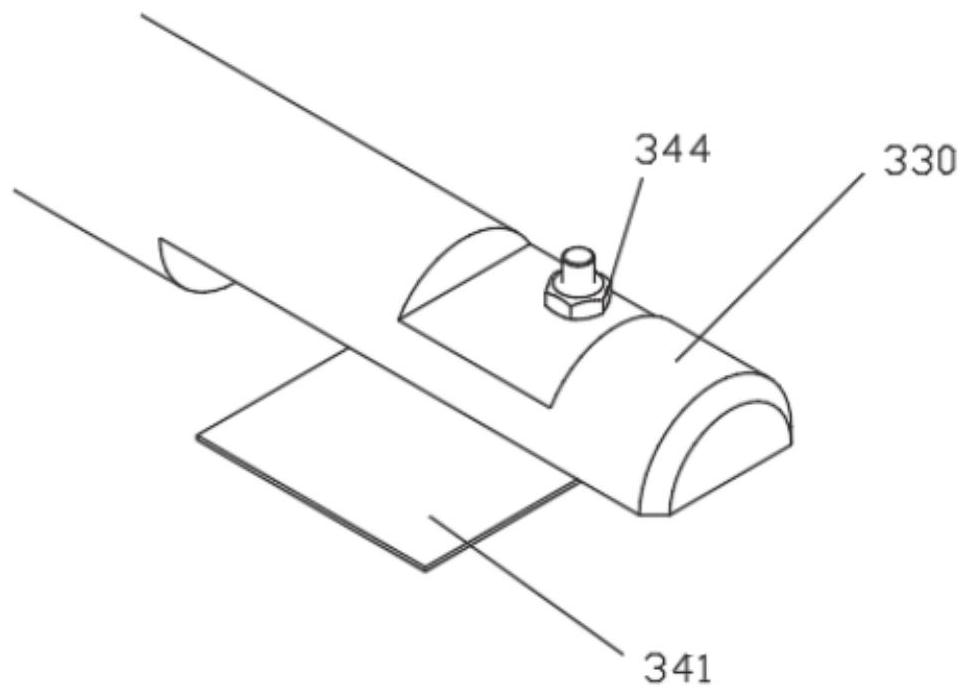

[0044] In a typical embodiment of the present invention, such as figure 1 As shown, a high-precision scraping equipment with adjustable scraping angle is proposed, which includes an electric translation platform 100, a scraper height adjustment mechanism 200, a scraper angle adjustment mechanism 300, a lifting table 400, an electric translation platform 100, and a scraper height adjustment mechanism. Mechanism 200, scraper angle adjustment mechanism 300, and lifting workbench 400 are all fixed in the cabinet. The lifting table 400 is connected with the electric translation table 100, and the electric translation table drives the lifting table to move in the horizontal direction; the scraper angle adjustment mechanism 300 is arranged on the top of the scraper height adjustment mechanism 200, and the scraper height adjustment mechanism 200 can drive the scraper angle adjustment mechanism 300 Move up and down to adjust the height of the scraper, the scraper angle adjustment mecha...

Embodiment 2

[0072] In this embodiment, compared with Embodiment 1, the difference is that: the scraping angle is 15°, the worm shaft 330 is rotated by manual rotation of the worm shaft, and the angle of the scraper 341 is adjusted to a desired angle.

Embodiment 3

[0074] In this embodiment, compared with the embodiment 1, the difference is that: the scraping thickness is 15 μm, and the differential head 210 is rotated to adjust to the desired height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com