Carrying insertion frame and stacking system for concrete molds and stacked concrete molds

A technology of concrete molds and molds, which is applied in the direction of external frames, manufacturing tools, and stacking of objects, which can solve the problems of concrete overflow, damage to the pouring surface, and limited use of the environment, and achieve the effects of convenient handling and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

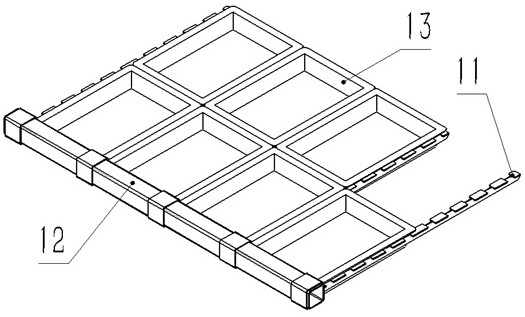

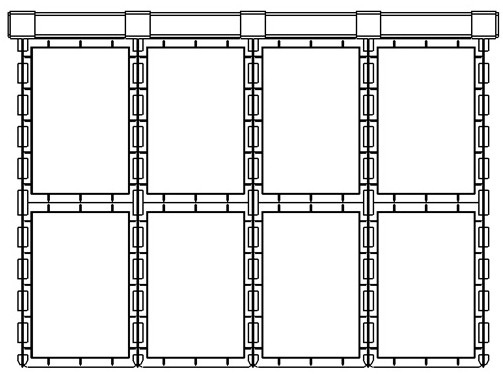

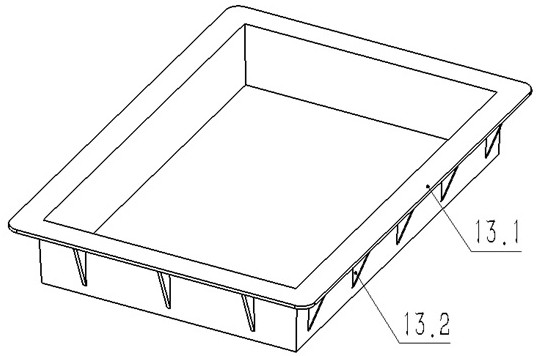

[0053] Embodiment 1, reference Figure 1 to Figure 4, a kind of concrete mold handling insert frame that one end of the insert plate is connected with the base frame, including the insert plate 11, the base frame 12, and the mold 13; the cross section of the insert plate 11 is T-shaped, and is composed of a vertical plate and a flat plate, and the flat plate has an opening, The opening corresponds to the ribs of the mould, and one end of the four parallel-placed inserts 11 is movably connected to the base frame 12, and the other end has a chamfer. There are 2 rows, 4 rows, and 8 molds 13 between the inserts 11. figure 1 One of the molds 13 is hidden to facilitate the observation of the part covered by it. There is a folded edge 13.1 on the upper edge of the mold 13. There is a rib 13.2 between the folded edge 13.1 and the side wall of the mold 13. The opening of the insert plate 11 leaves the rib 13.2 , when starting to use, adjust the distance between the plug-in boards 11, t...

Embodiment 2

[0054] Embodiment 2, refer to Figure 5 to Figure 8 , with reference to embodiment 1, a kind of concrete mold handling insert frame that the upper part of the insert plate is connected with the base frame, comprises insert plate 21, the base frame 22 that is connected as a whole two square tubes to form, mold 23, the section of insert plate 21 is I-shaped, the I-shaped lower plate has openings, and the openings correspond to the ribs of the mold 23 to avoid interference; the figure shows the state where the insert frame 21 is being inserted, the base frame 22 is connected to the hook of the crane, and the drive drives the insert frame to run Go to the front of the mold 23, adjust the height, the lower side of the inserting plate 21 is lower than the flange of the mold 23, the web of the inserting plate 21 is aligned between the two molds 23, and inserted forward until the end face of the inserting plate 21 is flush with the mold 23, At this moment, the opening of the inserting...

Embodiment 3

[0056] Embodiment 3, with reference to Embodiment 1, the embodiment of the rectangular cross-section inserting plate, as can be seen from the figure, adjacent mold flanges 13.1 are in contact with each other, and there is a space between the ribs 13.2 of adjacent molds, and this space can be Accommodate the flashboard of rectangular section, the flashboard inserts the folded edge 13.1 of mold 13, the benefit of rectangular section flashboard is needn't consider the interference of rib 13.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com